Vertical loading testing device for integral ring tunnel structure

A tunnel structure, vertical loading technology, applied in the testing, measuring devices, instruments, etc. of machines/structural components, which can solve the problem of the incompetence of the loading device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

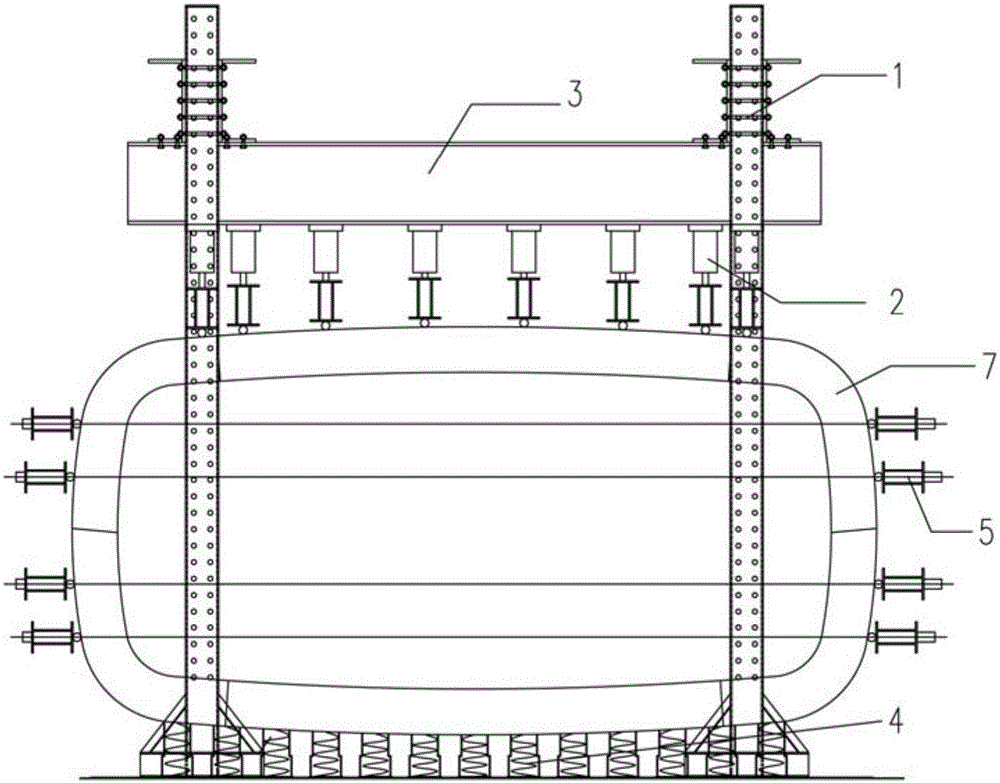

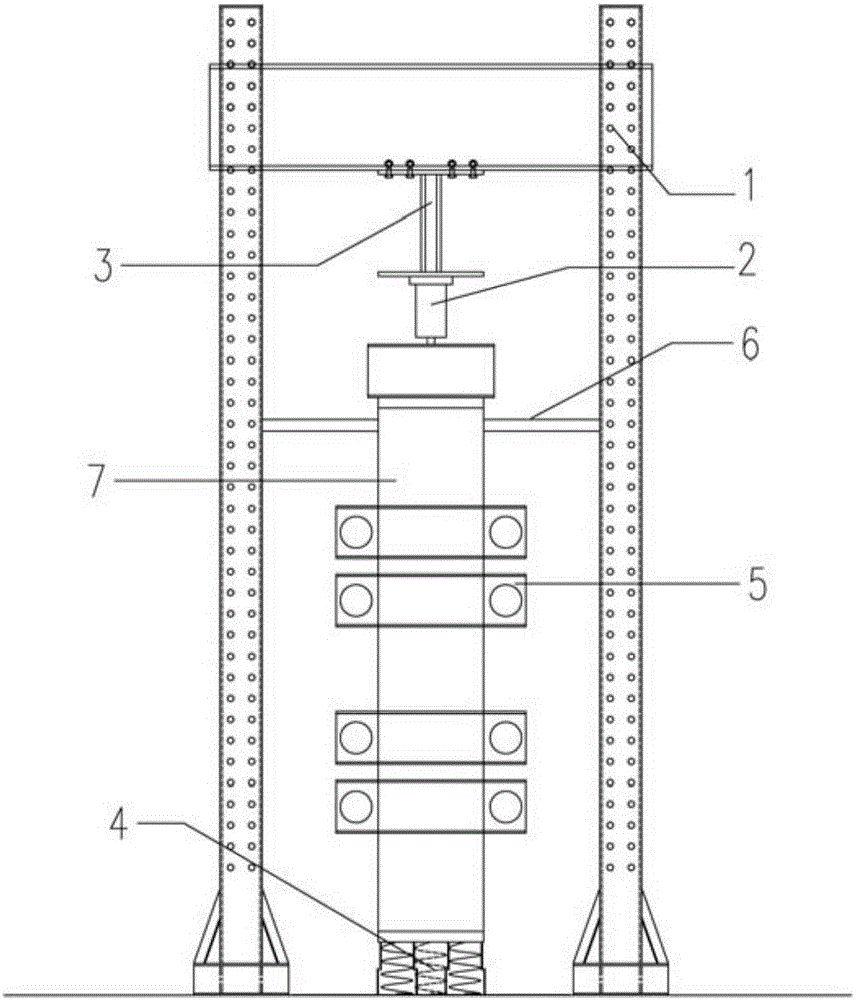

[0023] The vertical loading test device for the whole-ring tunnel structure includes a reaction frame composed of columns 1 and beams 3. The base of the reaction frame is provided with a spring support group 4, and the whole-ring tunnel structure is placed on the spring support group 4. 7. A number of jacks 2 are provided on the lower part of the beam 3. The upper ends of the jacks 2 are fixed on the beam 3, and the lower ends of the jacks are placed on the loading points on the whole-ring tunnel structure 7. Lateral loading components 5 are arranged on the left and right sides of the whole-ring tunnel structure 7. The lateral loading assembly 5 is left-right symmetrical. The lateral loading assembly 5 is composed of multiple sets of symmetrical tension self-balancing system loading devices, which are evenly distributed along the height direction of the entire ring tunnel structure. The tensioning self-balancing system loading devices include left and right loading beams, jacks,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com