Continuous composting device for organic refuse

A technology for organic waste and composting, applied in fertilization devices, organic fertilizers, organic fertilizer equipment, etc., can solve the problems of difficult to maintain composting temperature, difficult composting devices, and small processing capacity, so as to save the pretreatment process and shorten the composting cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The purpose of the invention of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the embodiments cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following embodiments.

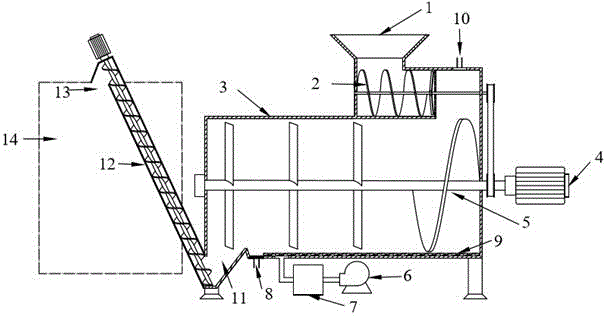

[0021] as attached figure 1 Described, a kind of organic waste continuous composting device, comprises the primary composting chamber 3 that is provided with inlet 1, discharge port 11, and the secondary composting chamber 14 that is connected with primary composting chamber 3 by screw conveyor 12, also includes Stirring device, feeding crushing device and air supply device,

[0022] The stirring device includes a horizontal agitator 5 arranged in the center of the primary composting chamber 3, a motor 4 located at one end of the primary composting chamber 3 and driven and connected to the horizontal agitator 5, and the motor 4 is a right-handed m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com