A wire gathering device for papermaking flat wire mesh

A technology of wire gathering device and flat wire mesh, which is applied in the field of wire collecting devices for drying flat wire mesh in papermaking, can solve the problems of no flat wire guiding equipment, etc., and achieve the effects of saving manpower and material resources, improving processing efficiency, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further described to facilitate the understanding of technical personnel.

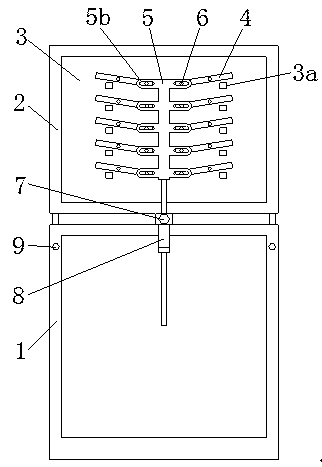

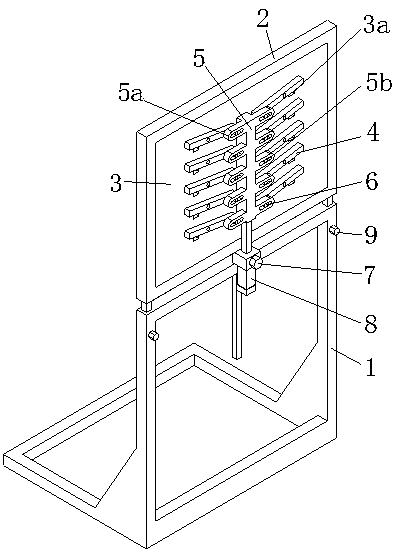

[0017] Such as Figure 1 to Figure 2 As shown, a wire gathering device for paper-making flat wire mesh includes a support frame 1, a sliding frame 2 that can move vertically along the support frame 1 is installed on the upper end of the support frame 1, and a fixed plate 3, the fixed plate 3 is evenly provided with square through holes 3a. When in use, the multi-strand flat yarn is guided by the through hole 3a, which ensures the processing quality of the flat yarn, improves the feeding efficiency of the flat yarn, and saves a lot of manpower and material resources.

[0018] The top of the through hole 3a is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com