Packaging machine for mosquito nail plastic boxes

A technology of plastic boxes and packaging machines, applied in the direction of packaging, etc., can solve problems such as slow speed, achieve the effects of speeding up production speed, realizing packaging automation, and reducing labor input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings. Preferred embodiments of the invention are shown in the accompanying drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein.

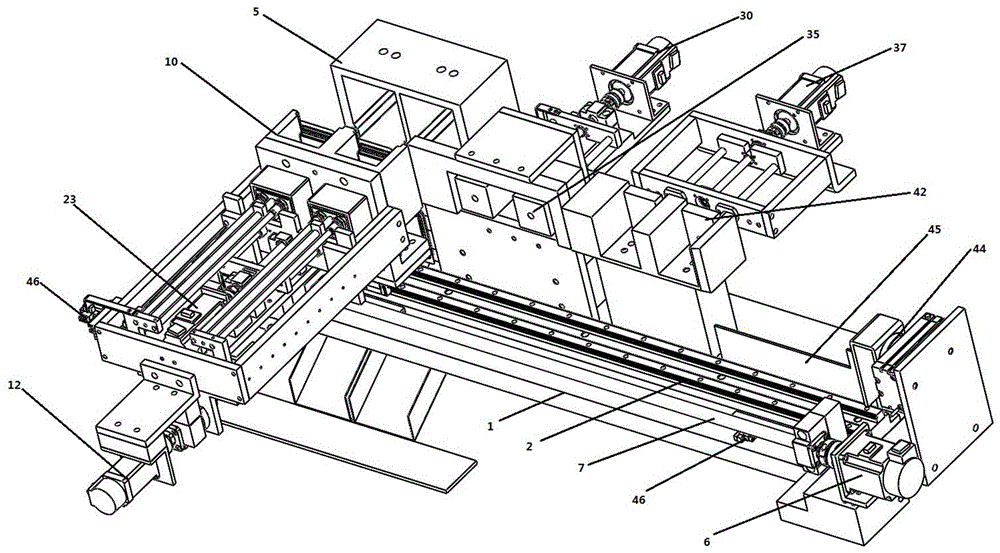

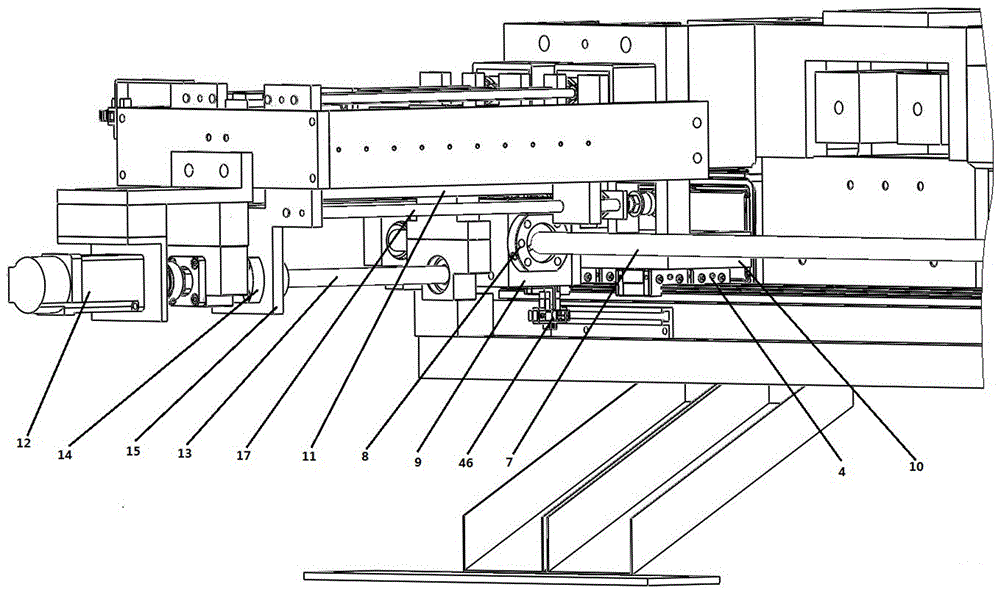

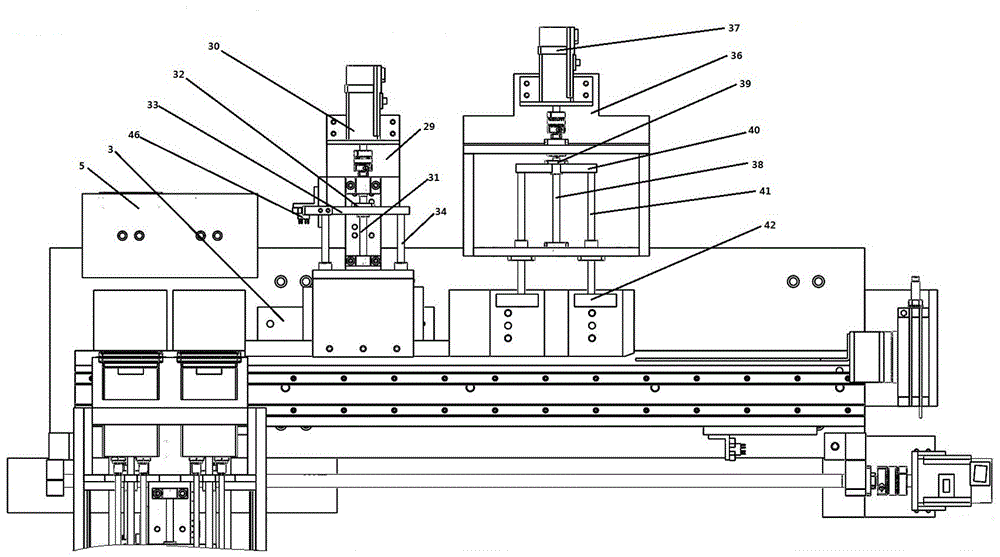

[0021] A mosquito nail plastic box packaging machine, comprising a working board 1, a first slide rail 2 and a support member 3 installed on the working board 1, a first slider 4 installed on the first slide rail 2, and a The adsorption device on the first slider 4, the plastic box placer 5 installed on one side, the pressing mechanism and the pushing mechanism installed on the middle support member 3, are installed on the other side of the working plate 1 close to the The rotating mechanism of the pusher mechanism is installed on the first screw mandrel 7 parallel to the first slide rail 2 on the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com