Conveying and installation vehicle for hanging-type full-automatic edge roller

An edge pulling machine and fully automatic technology, which is applied in the direction of transportation and packaging, motor vehicles, trolleys, etc., can solve the problems of affecting the operating radius of the vehicle, the small area of the installation site, and the low efficiency of transportation and installation, so as to reduce the installation cost. The effect of low production cost and easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

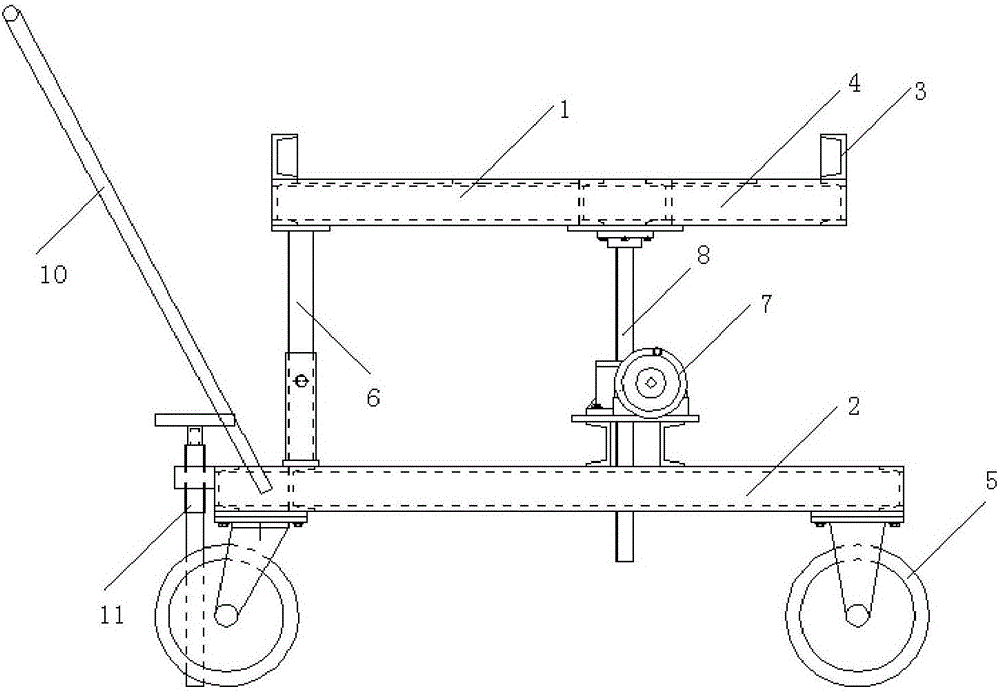

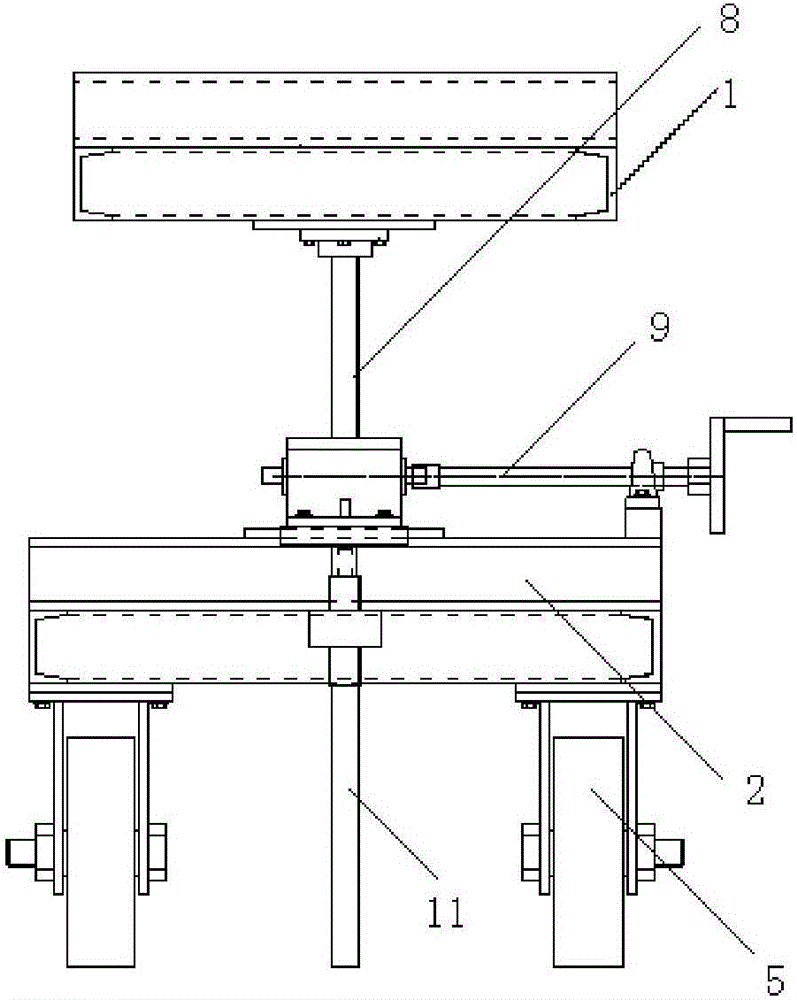

[0014] Referring to the accompanying drawings, a hanging type automatic edge pulling machine transportation and installation vehicle includes an installation platform 1 and a support platform 2, the two ends of the installation platform 2 are respectively provided with baffles 3, and the installation platform 2 is provided with a hanging edge Machine installation hole 4, roller 5 is installed on the bottom of support platform 2, guide bar 6 is installed between support platform 2 and the end of installation platform 1, lift 7 is installed in the middle of installation platform 1 and support platform 2, lift 7 includes fixed The elevating rod 8 connected to the bottom of the installation platform 1, and the rocking rod 9 that rotates laterally on the supporting platform 2, the elevating rod 8 and the rocking rod 9 are vertically arranged, and are connected through a bevel gear mechanism or a worm gear mechanism.

[0015] A push handle 10 is installed at the rear end of the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com