Preparation method for carbonized wood with super waterproof sterilization self-cleaning function

A carbonized wood and self-cleaning technology, applied in wood treatment, impregnating wood, manufacturing tools, etc., can solve the problem that carbonized wood does not have waterproof and anti-corrosion functions, and achieve the effect of solving water loss, maintaining lasting efficacy, and being environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

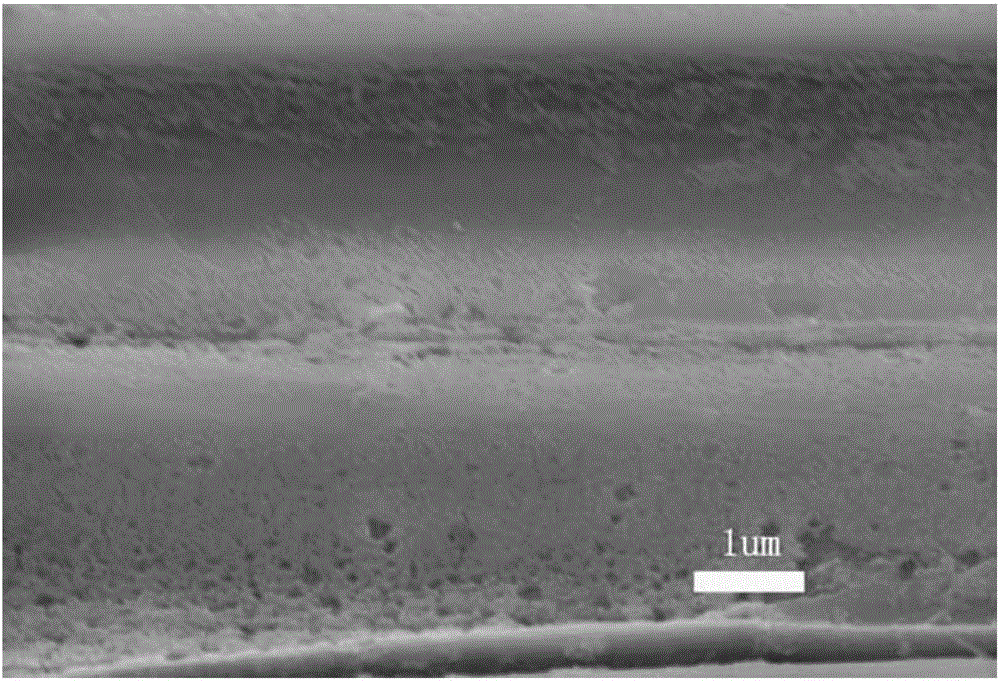

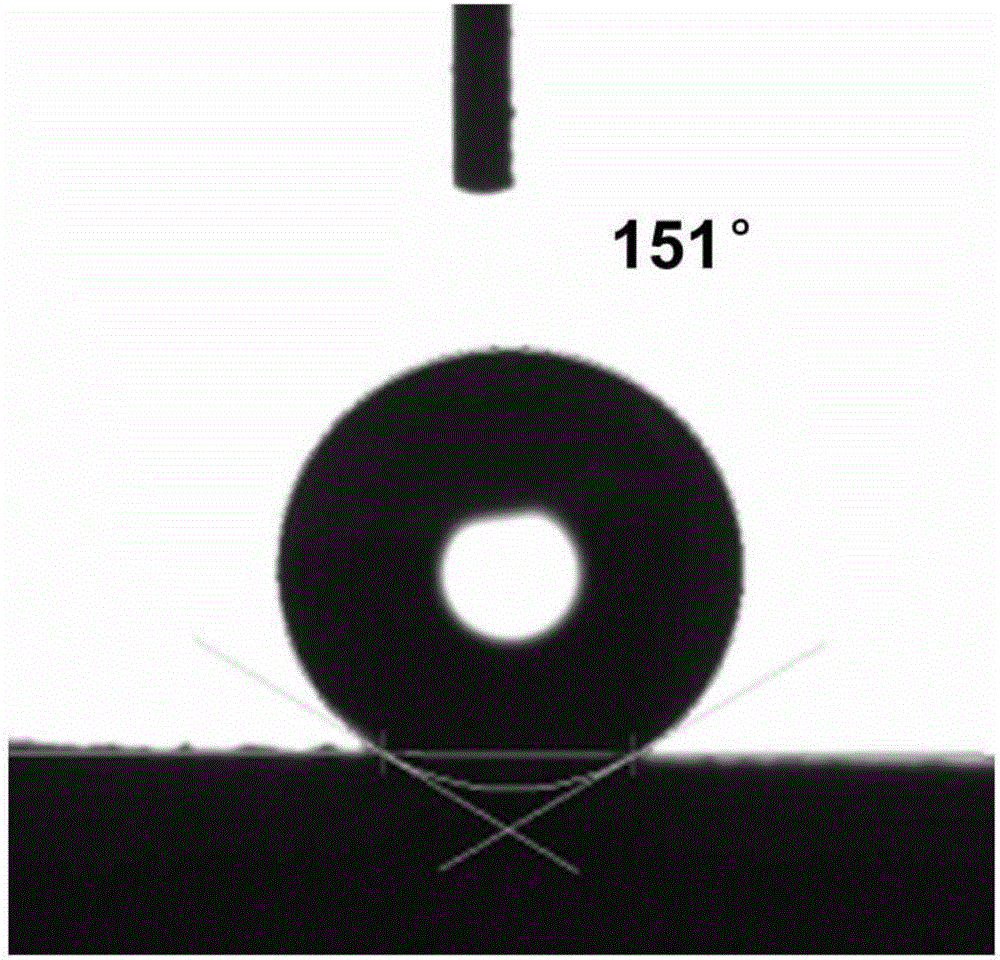

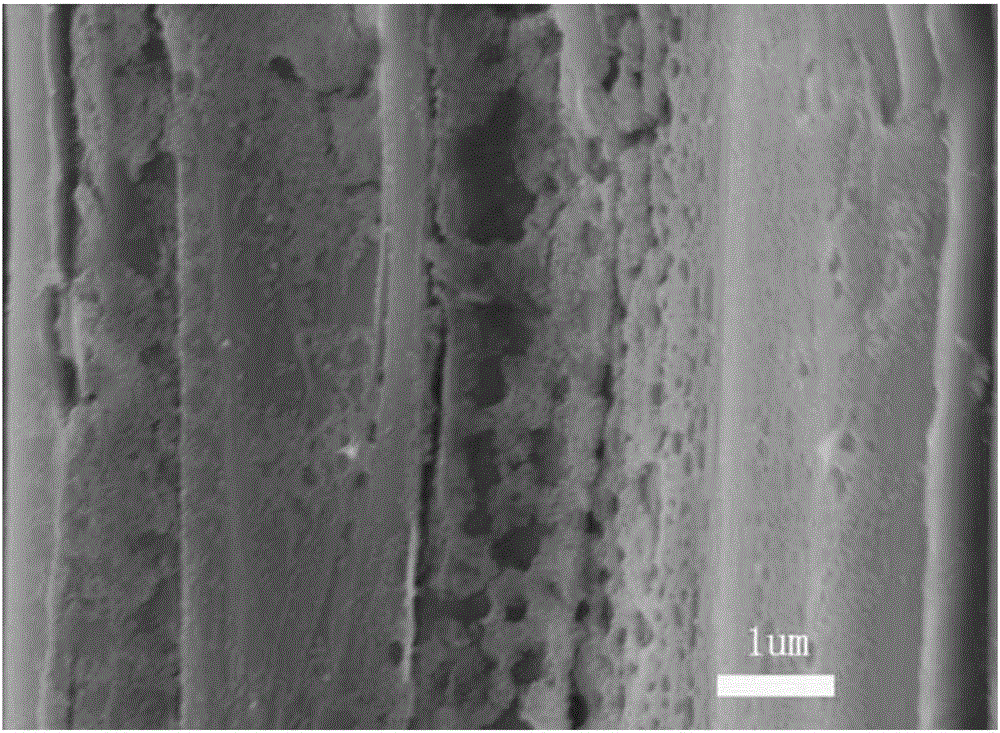

[0035] Specific implementation mode one: the preparation method of carbonized wood with ultra-waterproof, sterilizing and self-cleaning functions in this embodiment is carried out according to the following steps:

[0036] 1. Nanoparticle impregnation wood treatment:

[0037] ① Take 0.4-0.7 parts by mass of nano-titanium dioxide or nano-silver, disperse it in a mixture of 90-110 parts by mass of ethanol and deionized water, and disperse it ultrasonically in a 450-550 Hz ultrasonic instrument for 30-40 minutes;

[0038] ②Place the wood in the ultrasonic nanoparticle / ethanol-water mixed solution, then place it in a pressurized device, and impregnate it for 20 to 30 minutes under a pressure of 1 MPa;

[0039] ③Relieve the pressure, return to normal pressure, then take out the wood, wipe the surface of the wood, and place it at room temperature for later use;

[0040] 2. Hydrophobic treatment:

[0041] ① Mix 90-110 parts by mass of absolute ethanol and 0.01 parts by mass of hept...

specific Embodiment approach 2

[0051] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the diameter of nano-titanium dioxide in Step 1 is 5-50 nm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0052] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the diameter of the nano-silver in step 1 is 5-20 nm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com