Pollution-free heating coal combustion gasifier

A gasifier, non-polluting technology, applied in the field of non-polluting heating coal-fired gasifiers, to achieve the effects of reducing comprehensive living costs and social costs, high carbon monoxide content, and improving gas quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

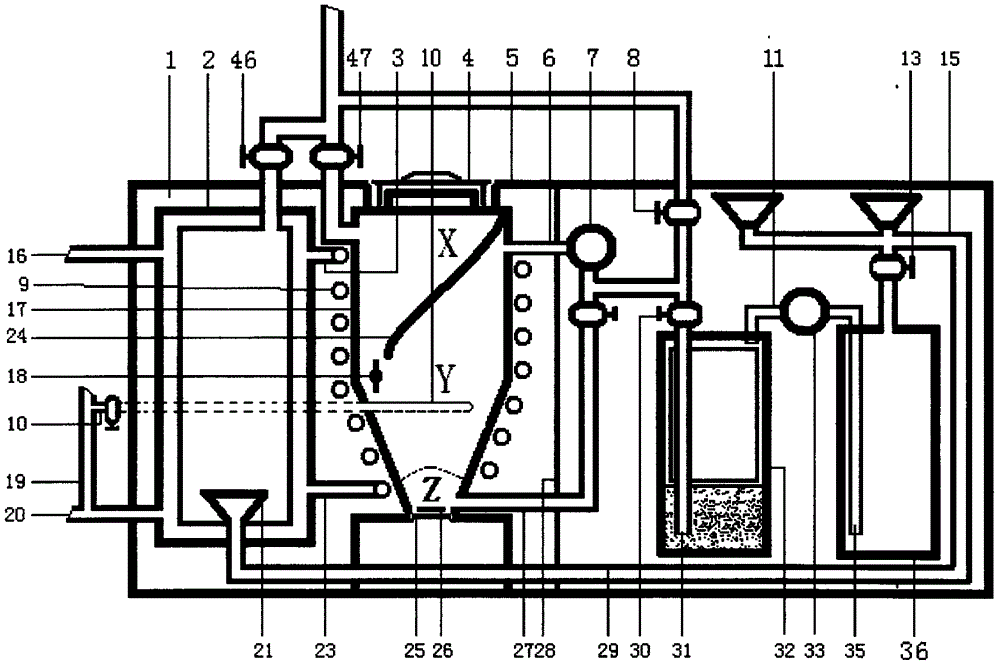

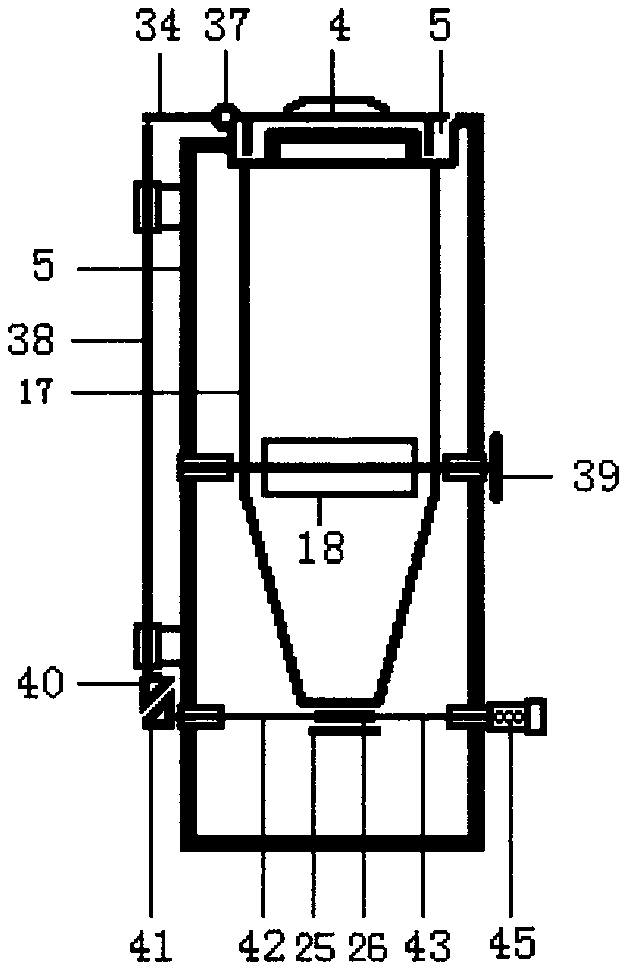

[0021] As shown in the accompanying drawings, the pollution-free heating coal-fired gasification furnace has a furnace body 5, a furnace liner 17, a hot water coil 9, a heating water heater 2, a gas purifier 32, a gas storage tank 36, and an air extractor 7 , an air pump 33, a grate closing mechanism, and a raw smoke utilization device.

[0022] There is an inclined partition 24 inside the furnace 17, which divides the inner cavity of the furnace into a coal storage chamber X and a gasification chamber Y. There is a coal inlet at the lower end of the inclined partition 24, and there is a coal inlet at the coal inlet. Switch 18, turn the knob 39, make the coal feed switch 18 be in an upright state, the coal will enter the gasification chamber Y from the coal storage chamber X, and carry out incomplete combustion and gasification in the gasification chamber Y and the lower combustion chamber Z.

[0023] Generate coal gas, then be sucked away by air extractor 7 and the pipeline 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com