A kind of ethyl acetate energy-saving production process

A technology of ethyl acetate and production process, which is applied in the field of energy-saving production process of ethyl acetate, can solve the problems of high water content, many side reactions, waste of finished product output, etc., and achieve mild esterification reaction, reduced dosage, and few side reactions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

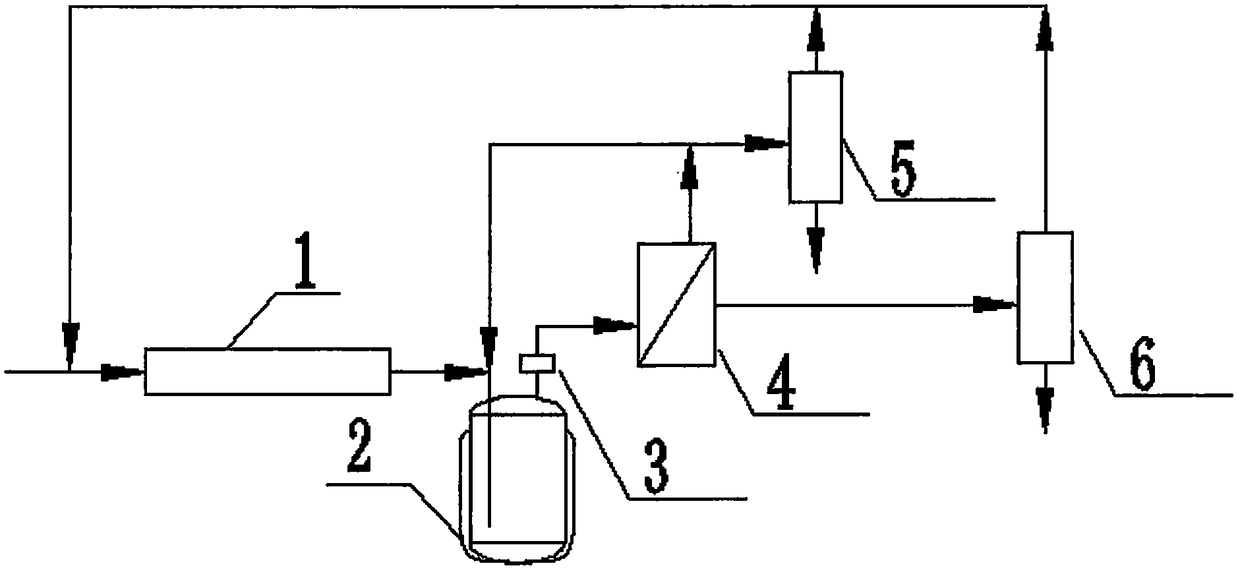

Method used

Image

Examples

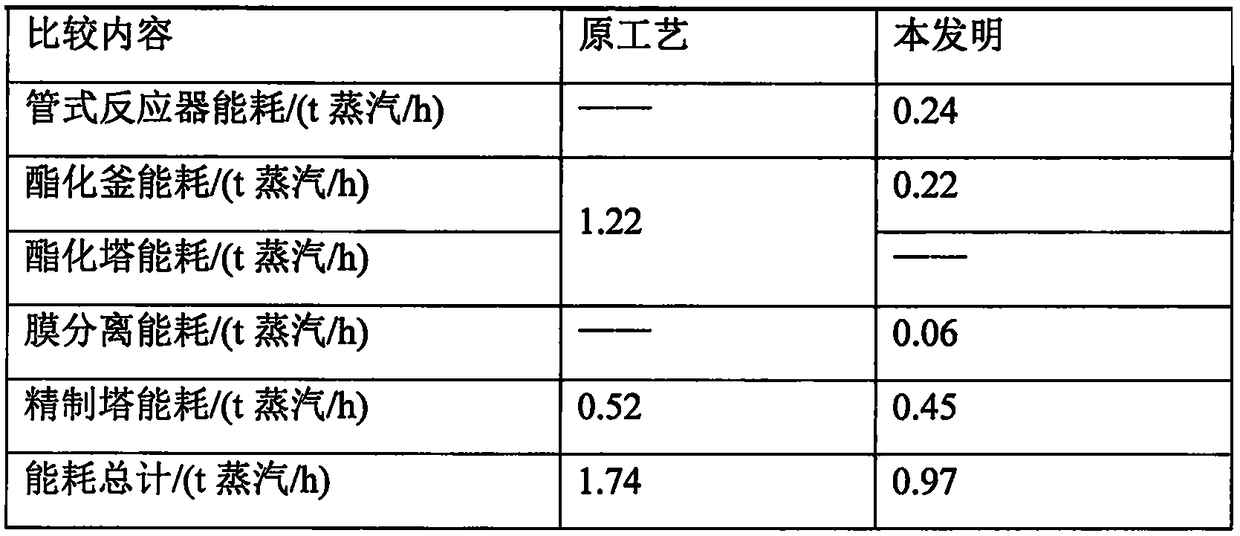

Embodiment 1

[0019] Taking a set of 50,000 t / a ethyl acetate test equipment as an example, the catalysts of the tubular reactor and the esterification kettle are all made of strong acidic macroporous cation exchange resin Amberlyst-15, and the membrane components of the membrane separation unit are made of a zeolite Molecular sieve membrane; the raw materials acetic acid and ethanol enter the tubular reactor 1 with a molar ratio of 1:1. 2. There is excess ethanol in the esterification kettle 2, the ethanol content is about 60wt.%, the internal reaction temperature of the esterification kettle is 75°C, and the azeotrope steamed from the top of the esterification kettle goes through the demister 3 to remove solid impurities and foam and then enters the membrane Separation unit 4, the entry temperature is 72°C, the vacuum pressure on the permeation side of membrane separation unit 4 is 300pa absolute pressure, the water phase after membrane treatment enters the recovery tower 6, and the water ...

Embodiment 2

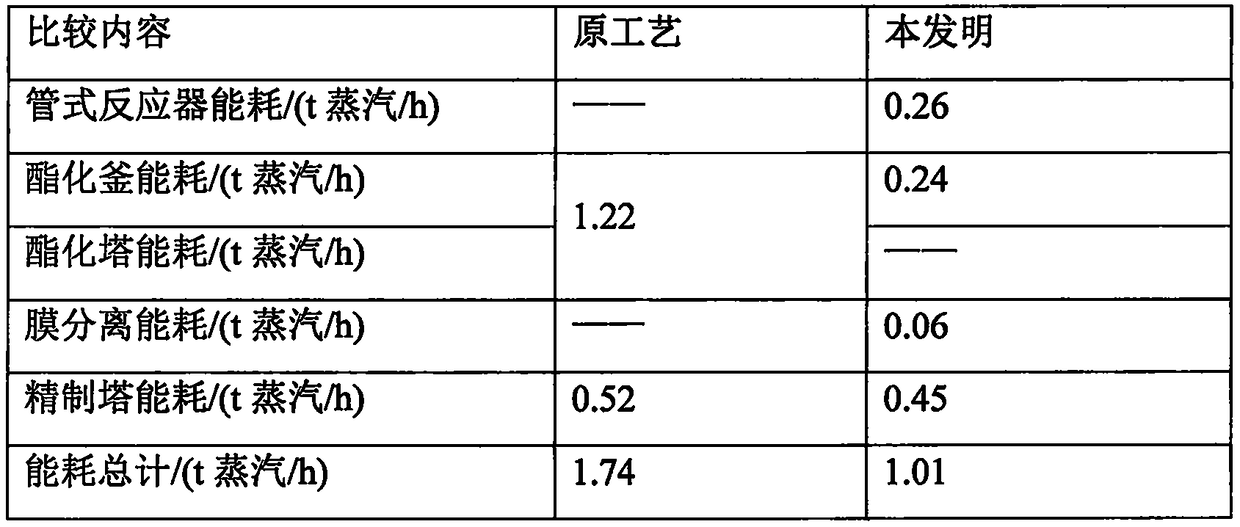

[0023] Taking a 50,000 t / a ethyl acetate large-scale test plant as an example, the tubular reactor and the esterification kettle use the strong acidic macroporous cation exchange resin Nafion NR50 as the catalyst, the membrane module uses a zeolite molecular sieve membrane, and the raw materials are acetic acid and ethanol Enter the tube reactor 1 for pre-reaction with a molar ratio of 1:1. The reaction temperature in the tube reactor is 80°C. About 50wt.%, the reaction temperature of the esterification tank 2 is 80 ° C, the azeotrope steamed from the top of the esterification tank passes through the demister 3 to remove solid impurities and foam, and then enters the membrane separation unit 4, and the temperature entering the membrane separation unit 4 is 75°C, the vacuum pressure on the permeation side of the membrane is 350pa absolute pressure, the water phase after membrane treatment enters the recovery tower 6, and the water content of the vapor phase distillate after memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com