Method for producing an electrical circuit, electrical circuit and motor vehicle electrical system with corresponding electrical circuit

A technology of electric lines and wire harnesses, which is applied in the field of motor vehicle power grids, can solve the problems of high cost and high cost, and achieve the effect of good roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

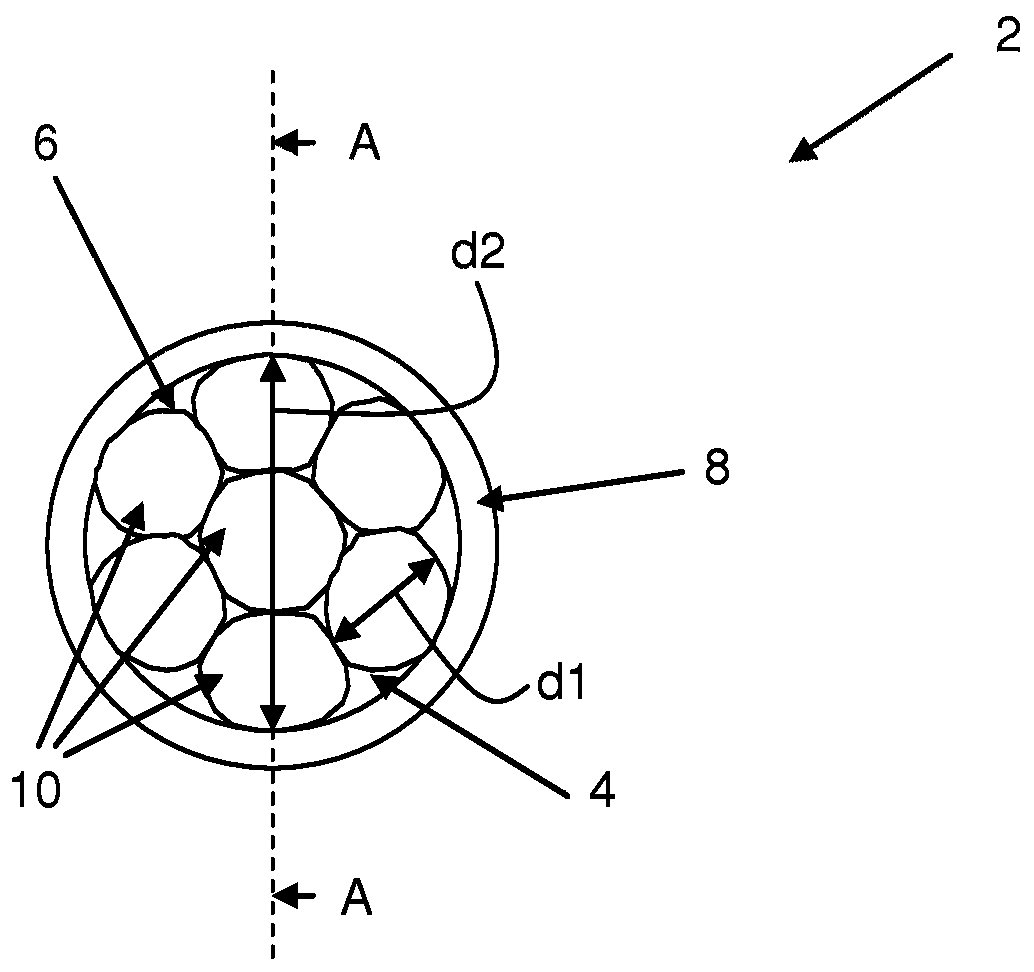

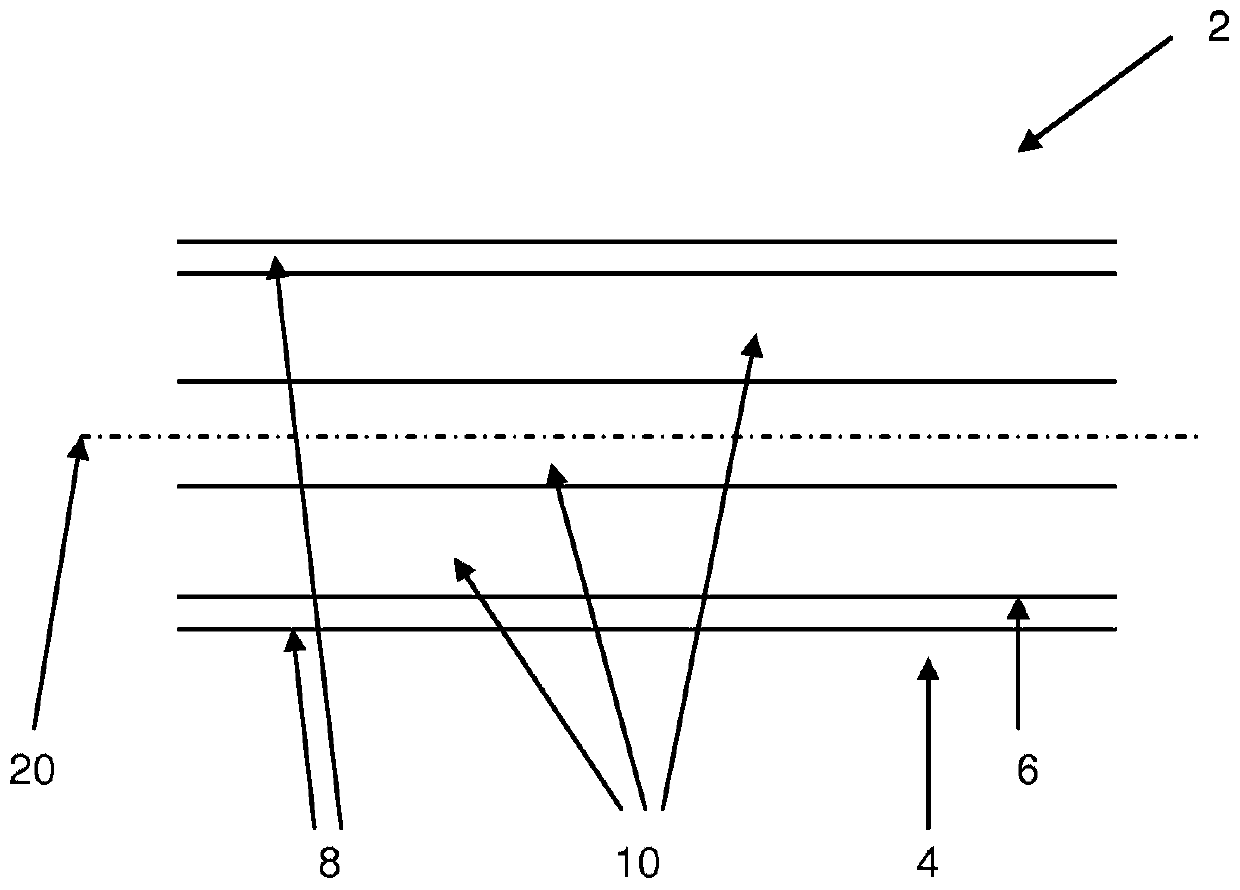

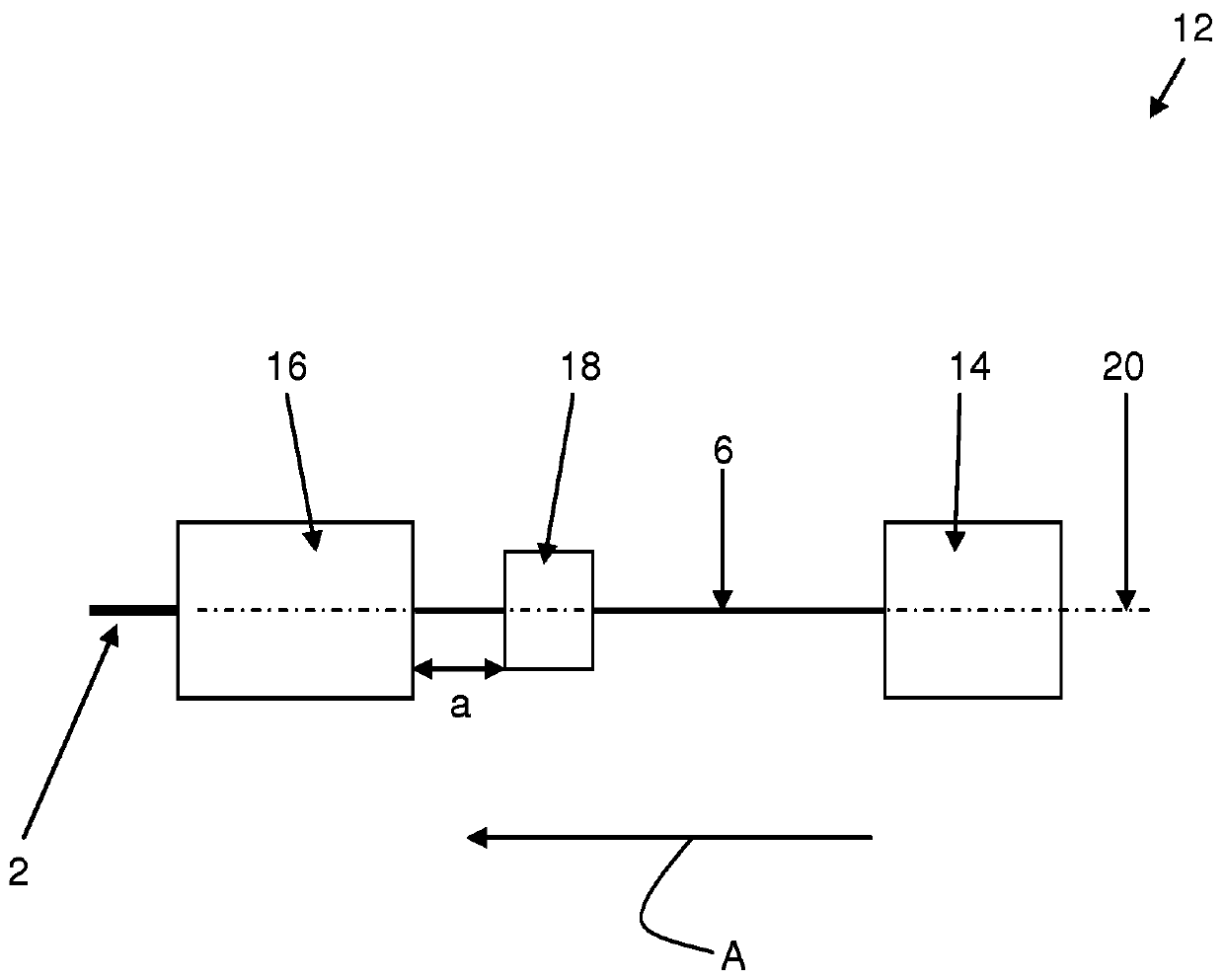

[0038] exemplarily described below and in figure 1 The line 2 of the single-core wire shown in the not-to-scale cross-sectional view is formed by the core wire 4 .

[0039] The line here comprises a wire harness 6 which is sheathed by an insulating sheath 8 made of plastic. In the exemplary embodiment, each strand 6 here consists of seven individual wires 10 with a diameter d1<1 mm, wherein six individual wires 10 rest on the central individual wire 10 at the periphery.

[0040] as in figure 1 As shown in , the wire harness 6 is embodied as a compressed wire harness 6 , and the individual wires 10 are correspondingly pressed against one another. Therefore, the thickness of each wire bundle 6 or the diameter of each wire bundle 6 is reduced, and the cross-sectional shape of each single wire 10 also deviates from a circular shape due to the deformation each single wire 10 undergoes during the pressing of the wire bundle 6 . The overall diameter d2 of the harness 6 is, for exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com