Winding head arrangement for electric rotating machine

A technology for a rotating electrical machine and a winding head, which is used in the manufacture of a winding head device for a rotating electrical machine and the field of rotating electrical machines, can solve the problems of increasing the overall length and weight of the rotating electrical machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

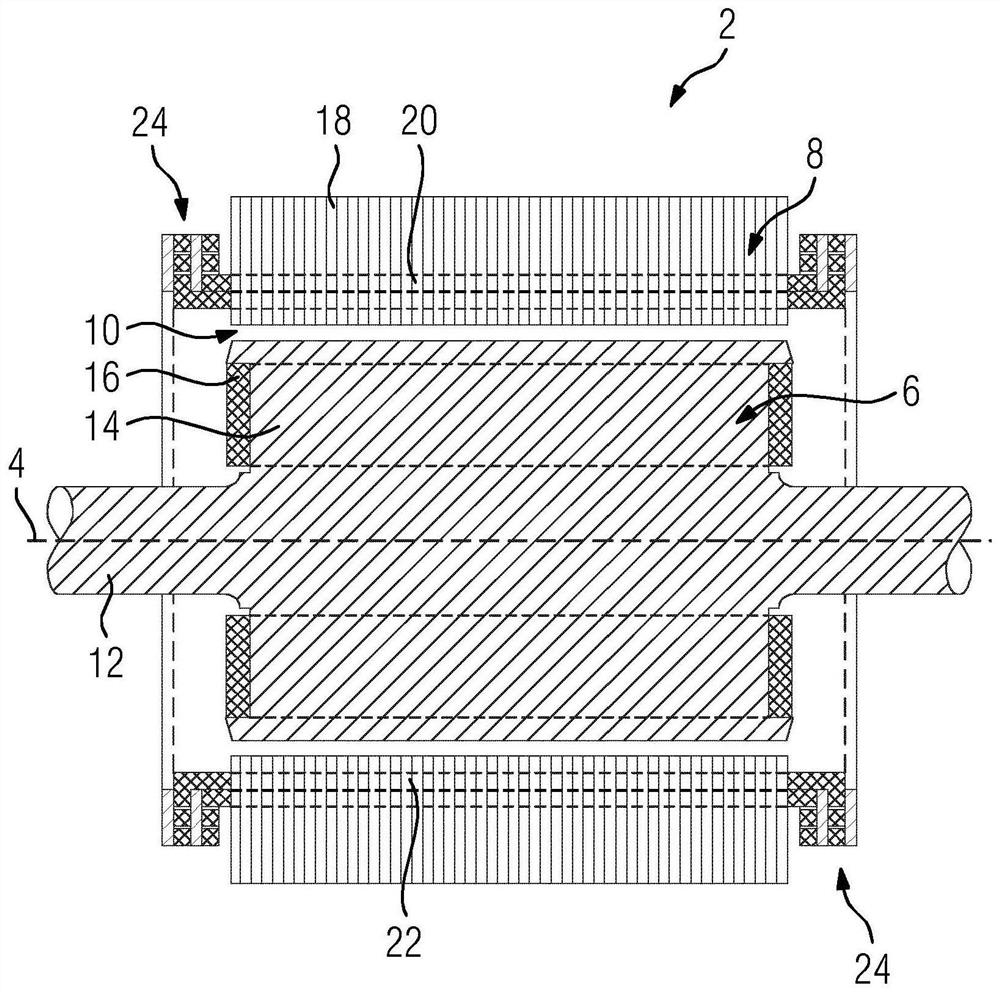

[0043] figure 1 A longitudinal section through a rotary electric machine 2 is shown, which is embodied as a synchronous machine by way of example. The synchronous machine has a rotor 6 rotatable about an axis of rotation 4 , embodied as an example as a salient-pole armature, and a stator 8 adjacent to the rotor 6 . Between the rotor 6 and the stator 8 there is a gap 10 which is embodied in particular as an air gap. The rotor shaft 4 defines an axial direction, a radial direction and a circumferential direction. The rotor 6 includes a shaft 12 and a salient pole 14 with an excitation winding 16 . Alternatively, the rotor 6 has permanent magnets or a squirrel-cage winding.

[0044] The stator 8 comprises a magnetically conductive, in particular eddy current-suppressing, stator element 18 , for example embodied as laminations, and a stator winding 20 . The stator winding 20 comprises a coil bar 22 , for example made of copper, which extends in the axial direction through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com