Automatic glue injection system and manufacturing method of porous ferrule assembly

A ferrule and glue injection technology, which is applied to the coupling of optical components, optical waveguides, light guides, etc., can solve problems such as low efficiency, difficulty in accurately controlling the amount of glue injected, and reduce the optical performance of ferrule components, so as to improve the glue injection efficiency. , improve the quality of manufacturing, the effect of precise glue injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

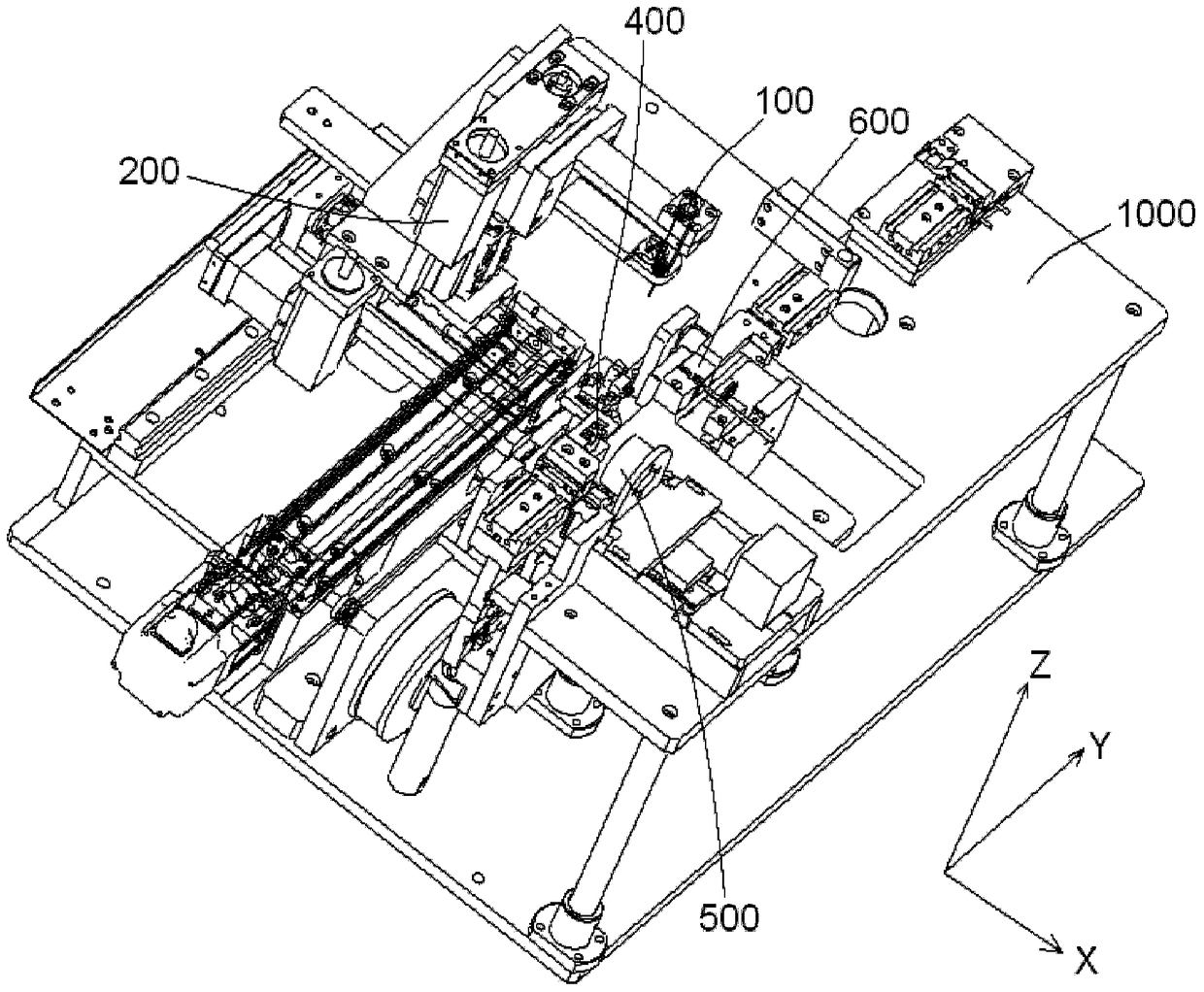

[0038] The technical solutions of the present invention will be further described in detail below through embodiments and in conjunction with the accompanying drawings. In the specification, the same or similar reference numerals refer to the same or similar parts. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, and should not be construed as a limitation of the present invention.

[0039] Furthermore, in the following detailed description, for convenience of explanation, numerous specific details are set forth in order to provide a thorough understanding of the embodiments of the present disclosure. Obviously, however, one or more embodiments may be practiced without these specific details. In other instances, well-known structures and devices are shown in diagram form in order to simplify the drawings.

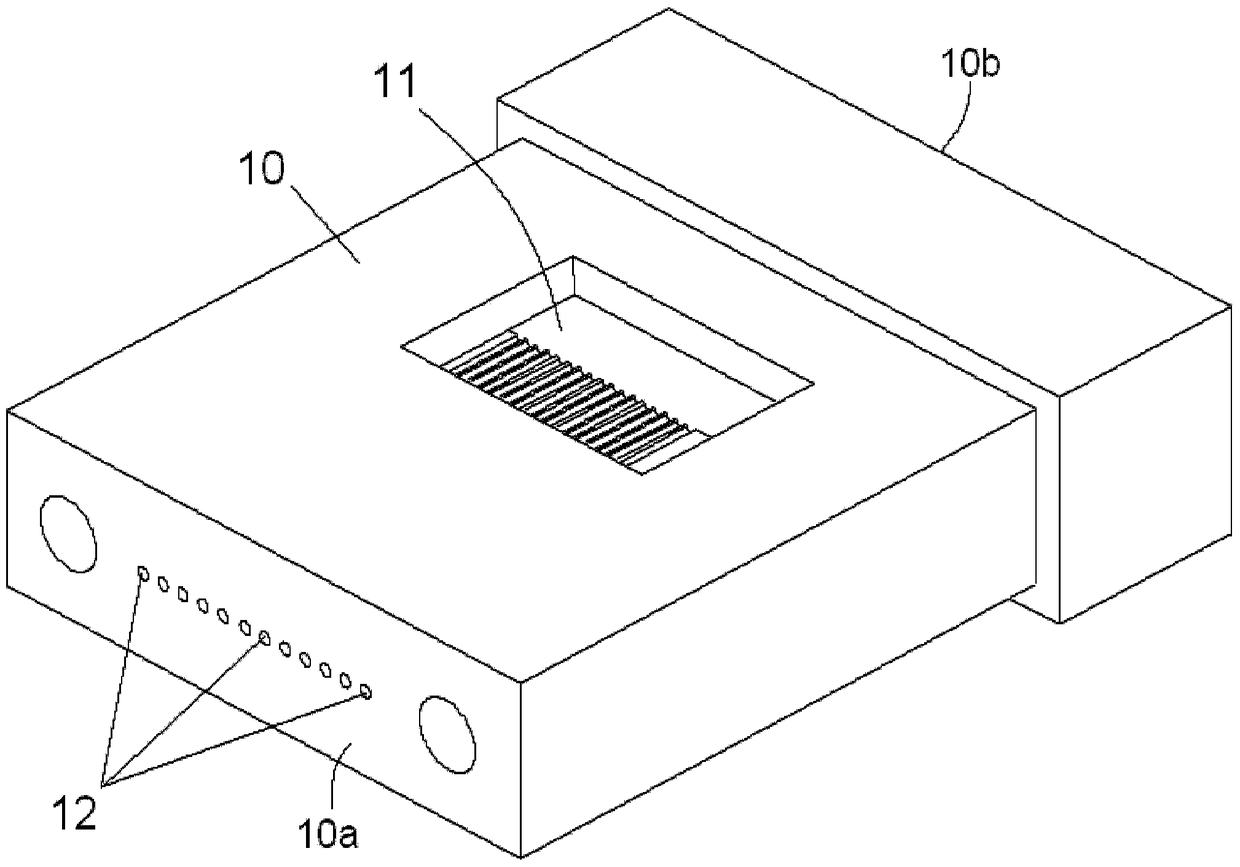

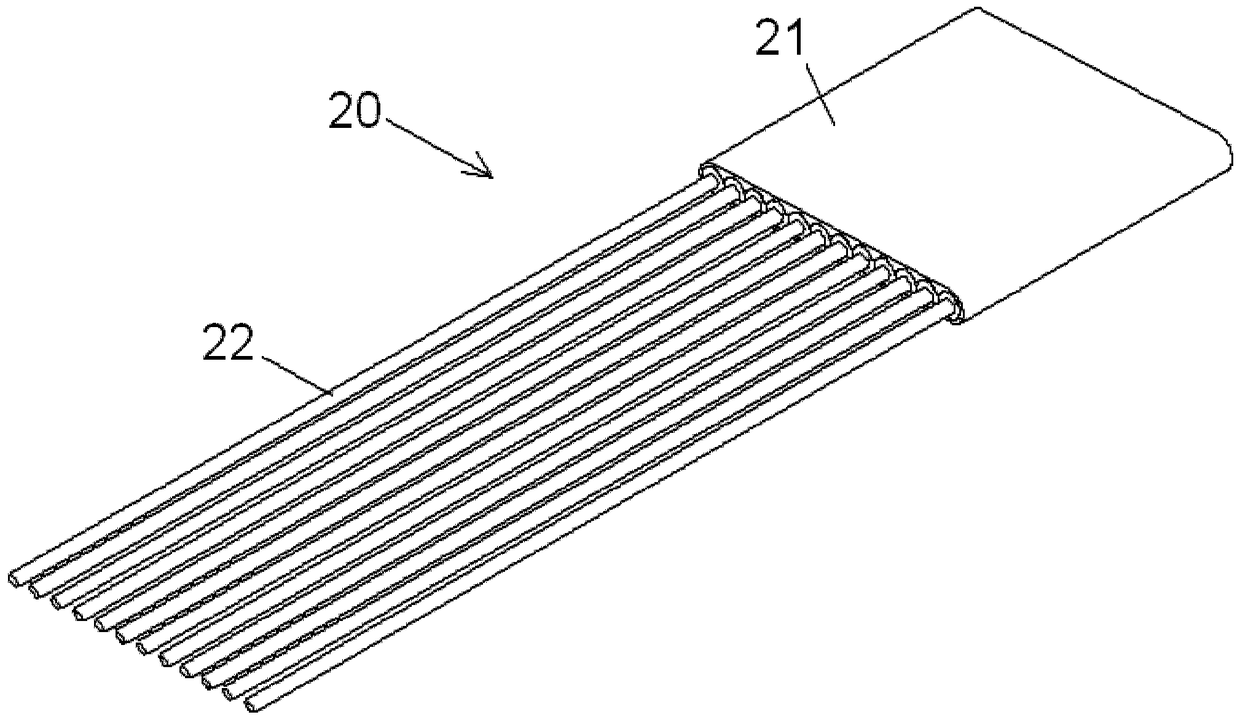

[0040] According to a gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com