Air bearing

A stage and air flotation technology, which is applied in the direction of instruments, measuring instrument components, measuring devices, etc., can solve the problems of uneven flow rate at the air outlet, difficult level effect of the substrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

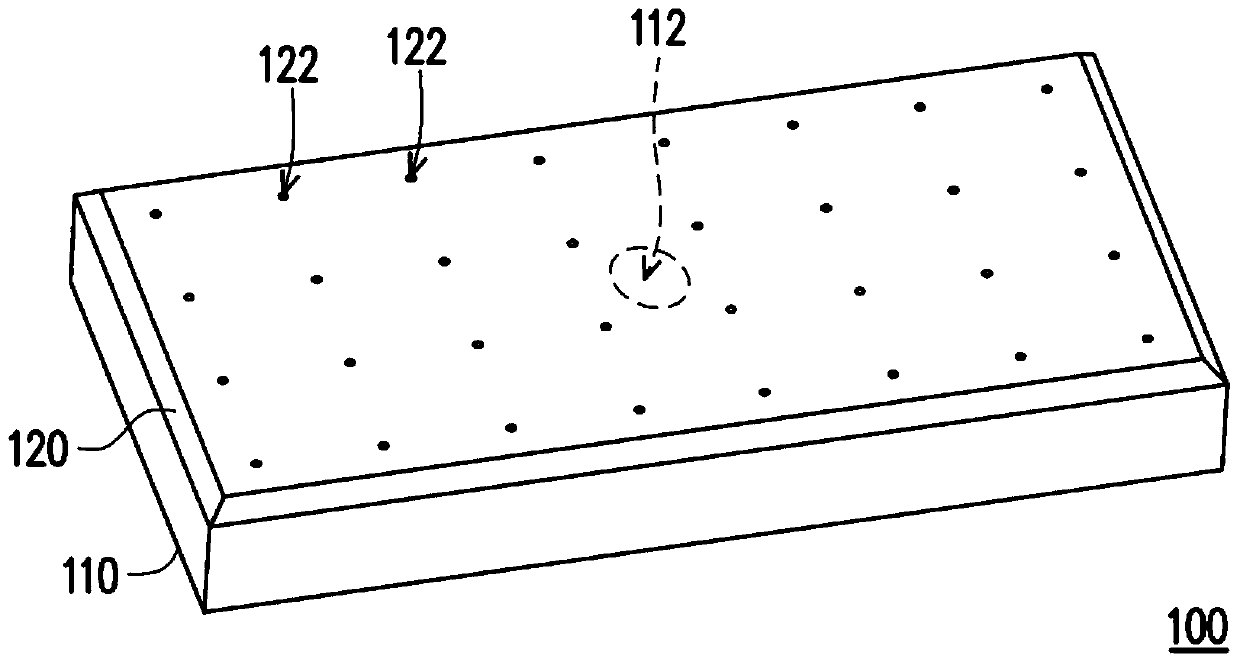

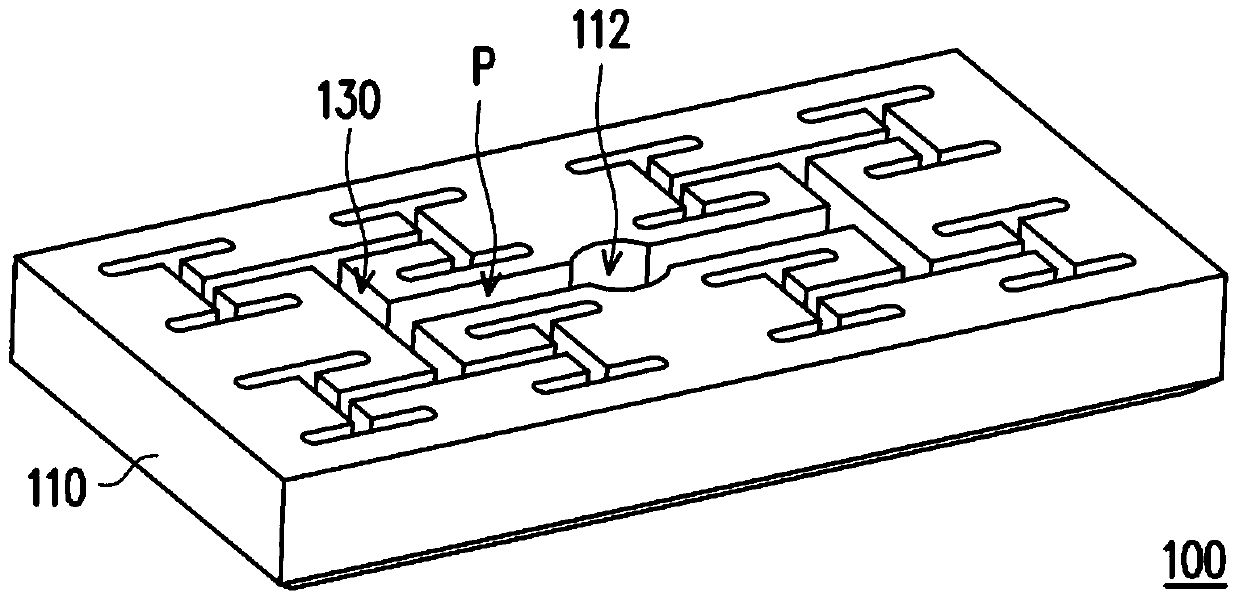

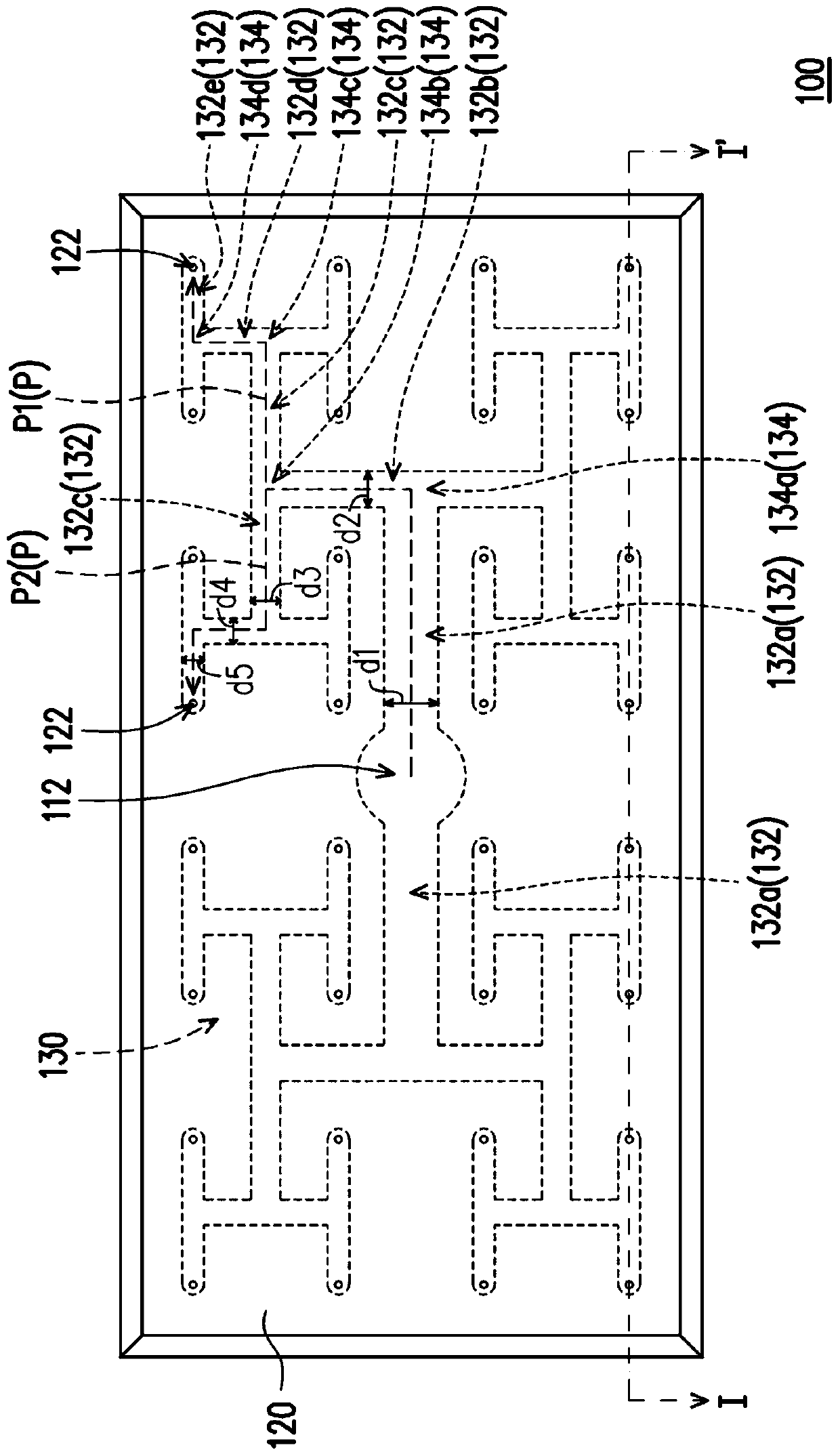

[0025] figure 1 is a schematic diagram of an air bearing platform according to an embodiment of the present invention. figure 2 yes figure 1 A partial schematic diagram of the air bearing platform. Please refer to figure 1 and figure 2 , in this embodiment, the air bearing platform 100 includes a bottom layer 110 , a top layer 120 and an air chamber 130 . The bottom layer 110 has an air inlet 112 . The top layer 120 is disposed above the bottom layer 110 and has a plurality of air outlets 122 . The air chamber 130 is located between the top layer 120 and the bottom layer 110 , and communicates with the air inlet 112 on the bottom layer 110 and the air outlet 122 on the top layer 120 . For example, in this embodiment, the air chamber 130 is fabricated on the bottom layer 110 (such as figure 2 shown), but in other non-illustrated embodiments, the air chamber 130 can also be fabricated on the top layer 120 , or be fabricated in another layer member between the top layer...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap