Double wishbone or mcpherson suspension with transverse leaf spring and dimensioning method thereof

A technology of transverse plates and suspensions, applied in the direction of suspensions, elastic suspensions, vehicle springs, etc., which can solve the problems of reducing vehicle performance, increasing weight and size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

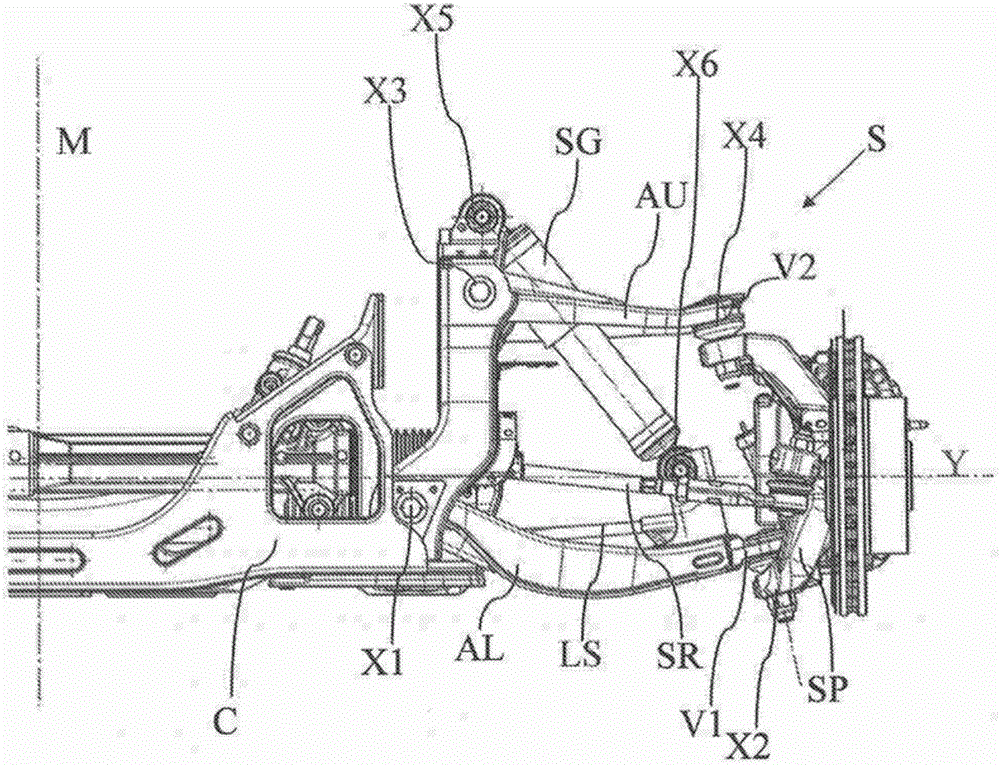

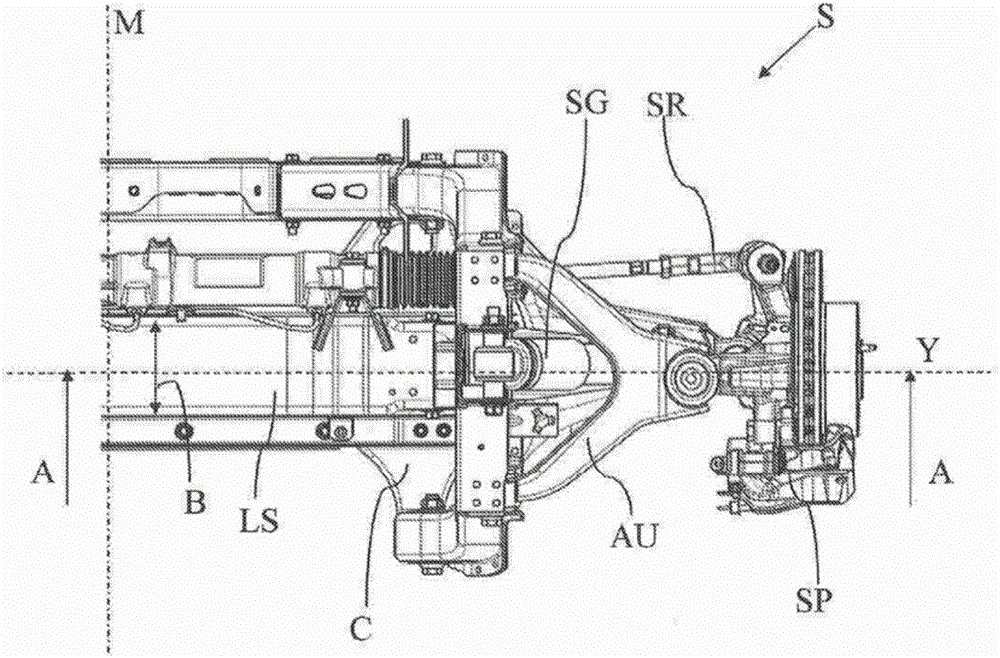

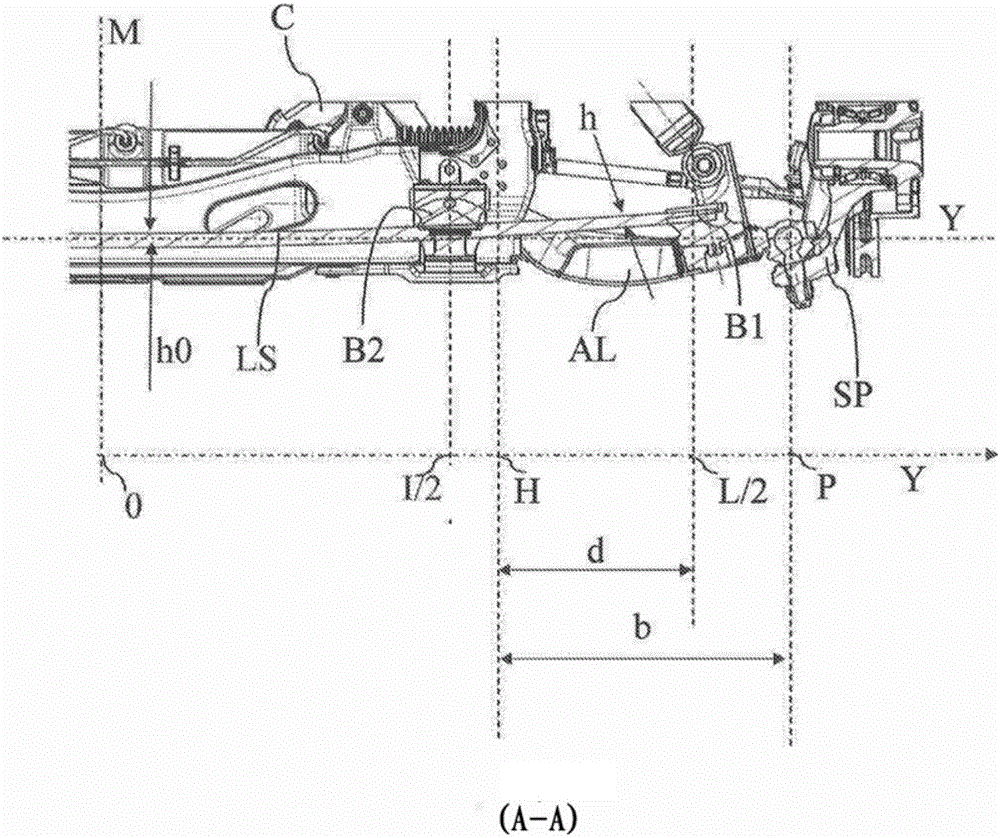

[0026] figure 1 A quadrilateral suspension with transverse leaf springs dimensioned by the method of the invention is shown. The method of the invention is also applicable to MacPherson arrangements.

[0027] Since the axles are symmetrical about the axis M, only the half shafts are shown.

[0028] The fixed portion C defines the structural part of the body to which the suspension of the same axle is connected.

[0029] The lower arm AL is shown generally substantially V-shaped or Y-shaped, the two forked ends of the lower arm AL being hinged to the fixed part C by means of a hinge X1 . The apex V1 of the lower arm opposite the aforementioned forked end is connected to the lower part of the hub SP by means of a ball joint X2.

[0030] Also shown is the upper arm AU, also generally substantially V-shaped or Y-shaped, the two forked ends of which are hinged to the fixed part C by means of a hinge X3 above the hinge X1. The apex V2 of the upper arm AU is connected to the uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com