Needle cylinders for circular knitting machines

A technology of circular weft knitting machine and needle cylinder, which is applied in the directions of knitting, weft knitting, textile and paper making, etc., can solve the problems of expensive, abnormal sharpness and mutual interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

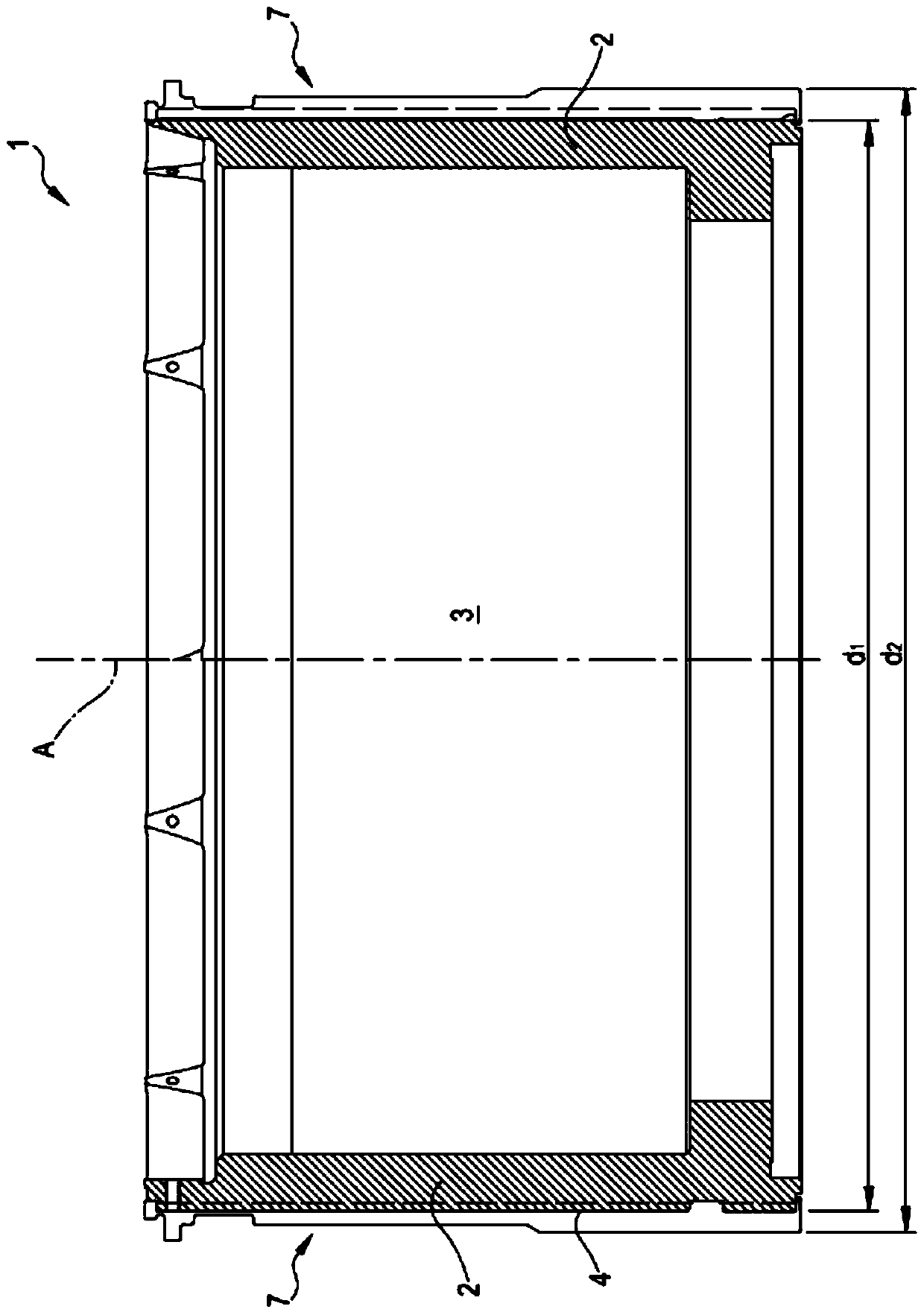

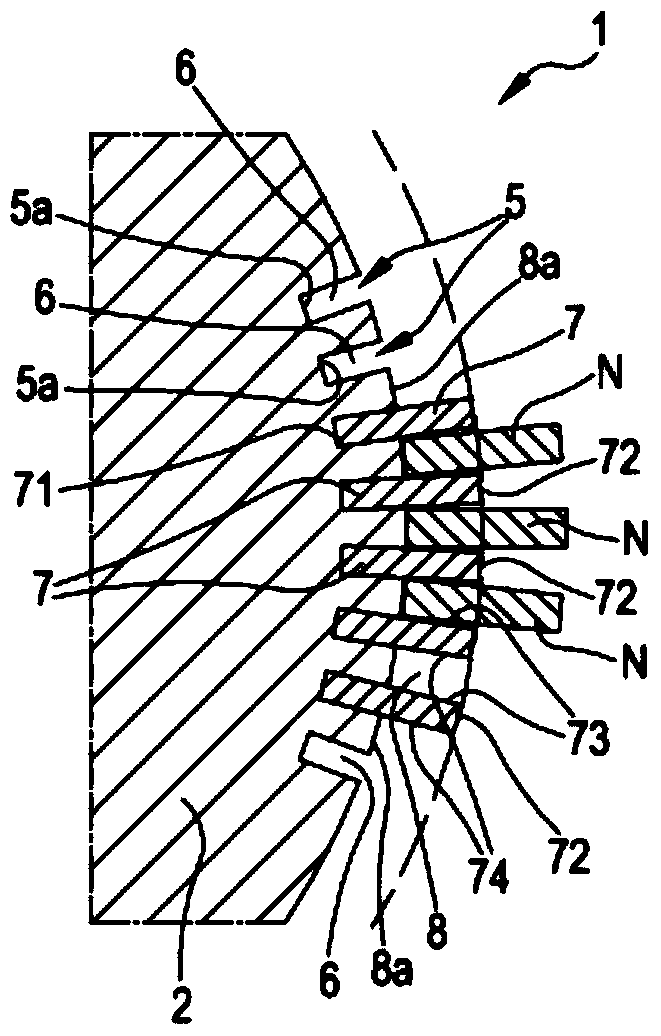

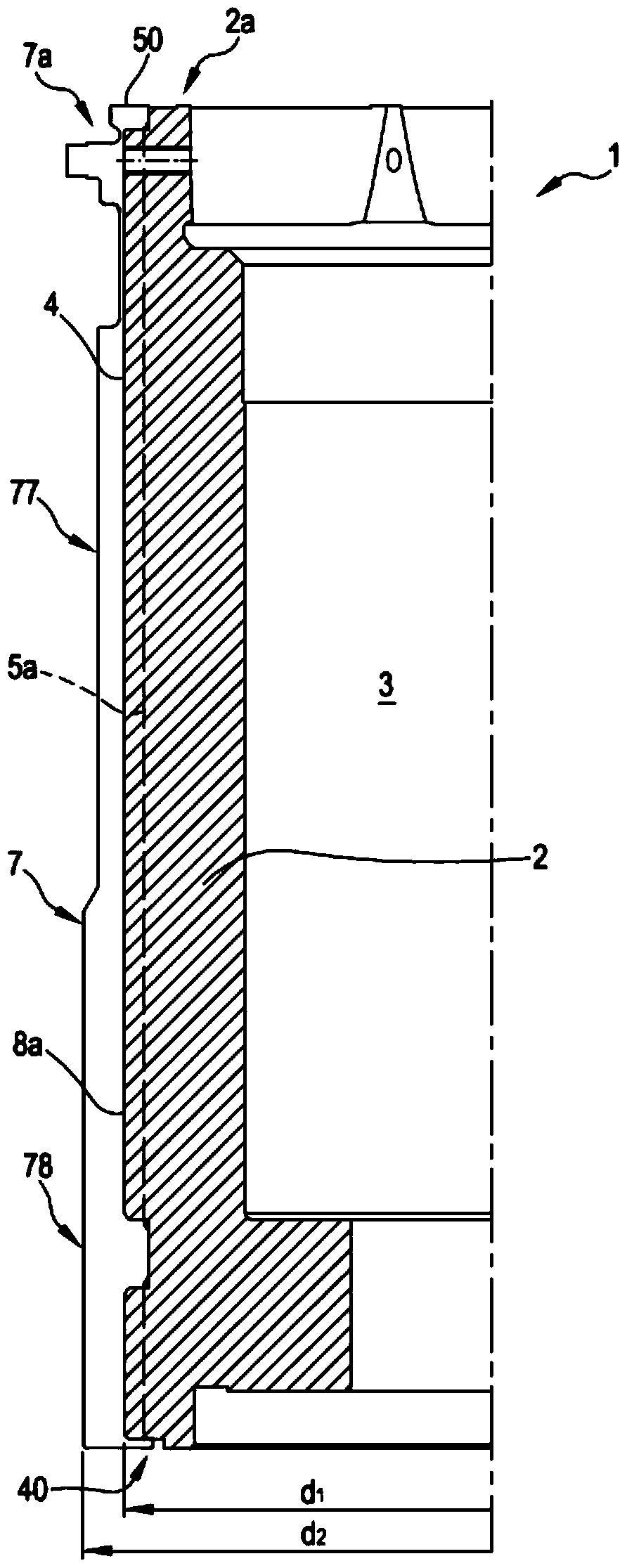

[0098] With reference to the above-mentioned figures, reference numeral 1 denotes the entire cylinder for a circular knitting machine according to the present invention. In general, the same reference numbers are used for the same or similar elements, even if these elements are present in different embodiments.

[0099] figure 1 A possible embodiment of a cylinder according to the invention for a circular knitting machine with some parts removed is shown. In particular, the description of the knitting machine focuses on the cylinder and the elements connected to the cylinder (especially the partition wall), and the description of the knitting machine facilitates the understanding of the present invention. The base of the knitting machine, the control elements of the knitting head, the part containing the central processing unit and other parts of the knitting machine are not shown in detail, since these are of known and conventional type. From the perspective of knitting tec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com