Cylinder unit of printing press

A technology of printing presses and cylinders, applied in printing presses, rotary printing presses, printing, etc., can solve the problems of inability to adjust printing pressure with high precision, complexity, etc., and achieve the effect of simple structure and high-precision printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

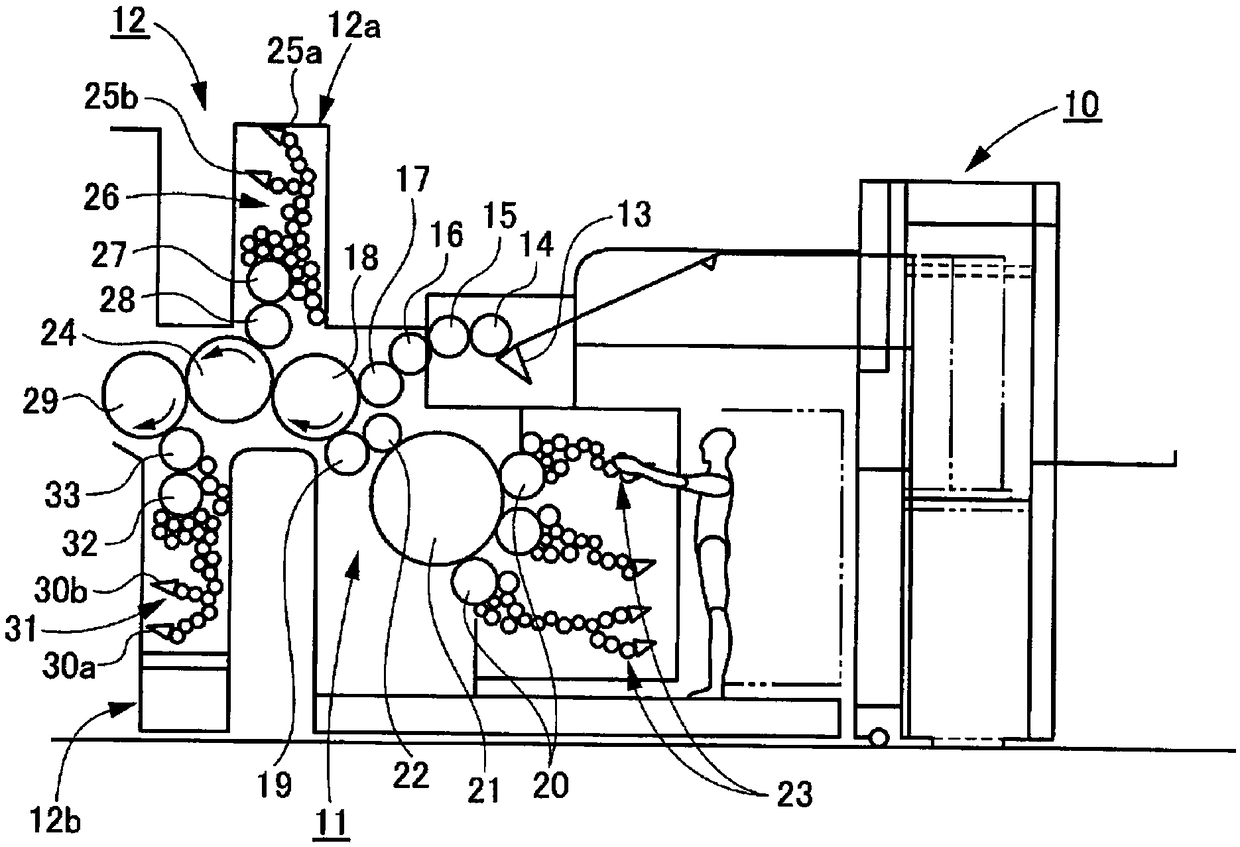

[0049] figure 1 The polychromatic printing press shown is a printing press that combines a polychromatic printing section and a double-sided offset printing section.

[0050] That is, as figure 1 As shown, the multicolor printing machine includes a supply unit 10, a multicolor printing unit 11, a double-sided offset printing unit 12, and a discharge unit (not shown) in this order from the upstream side toward the downstream side in the paper feeding direction. As a result, the sheets fed from the feeding section 10 are transferred one by one to the impression cylinder 18 of the multi-color pattern printing section 11 via the oscillating device 13 and the four transfer cylinders 14, 15, 16, and 17, and are then fed to the between the impression cylinder 18 and the blanket cylinder 19.

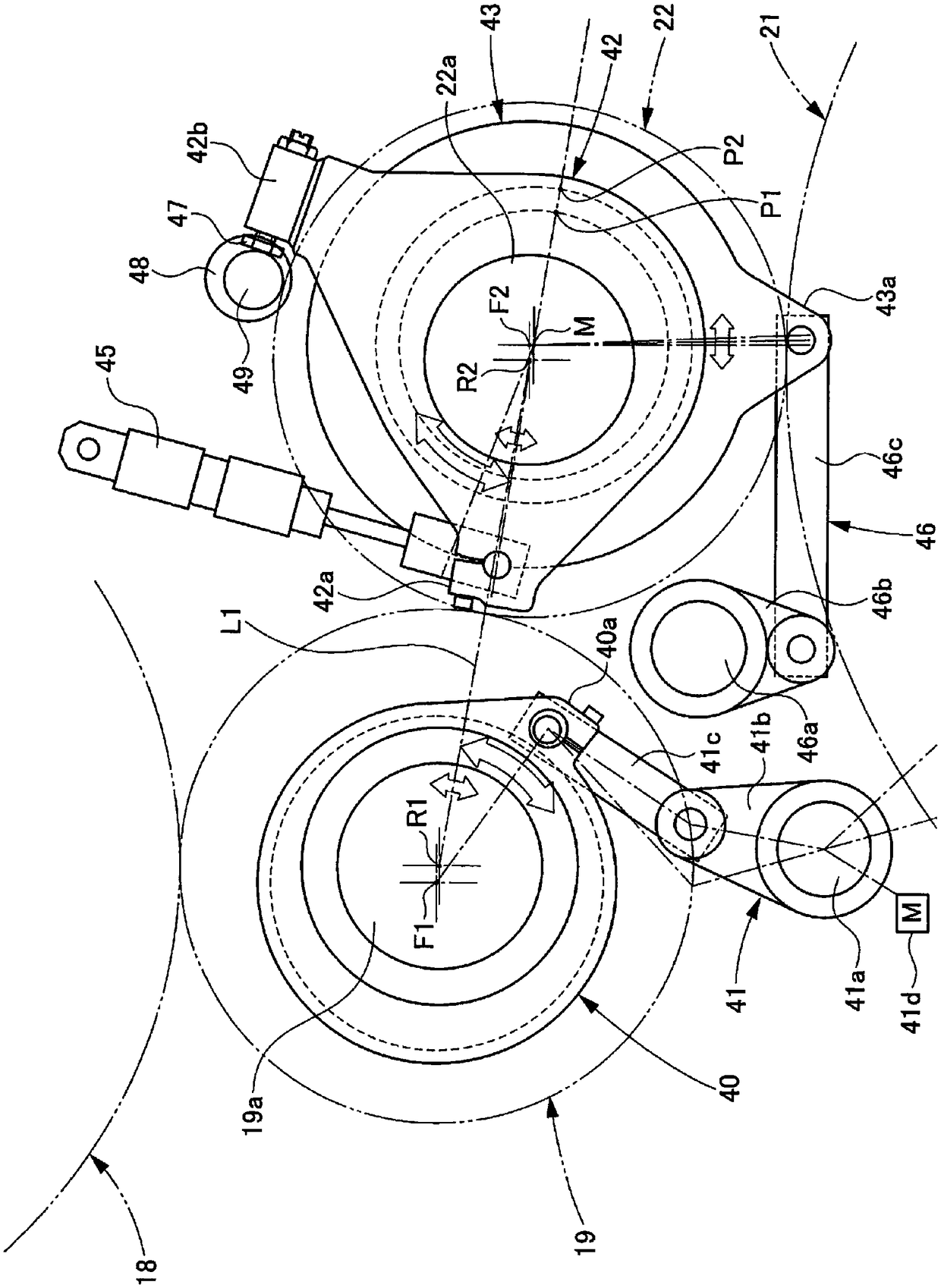

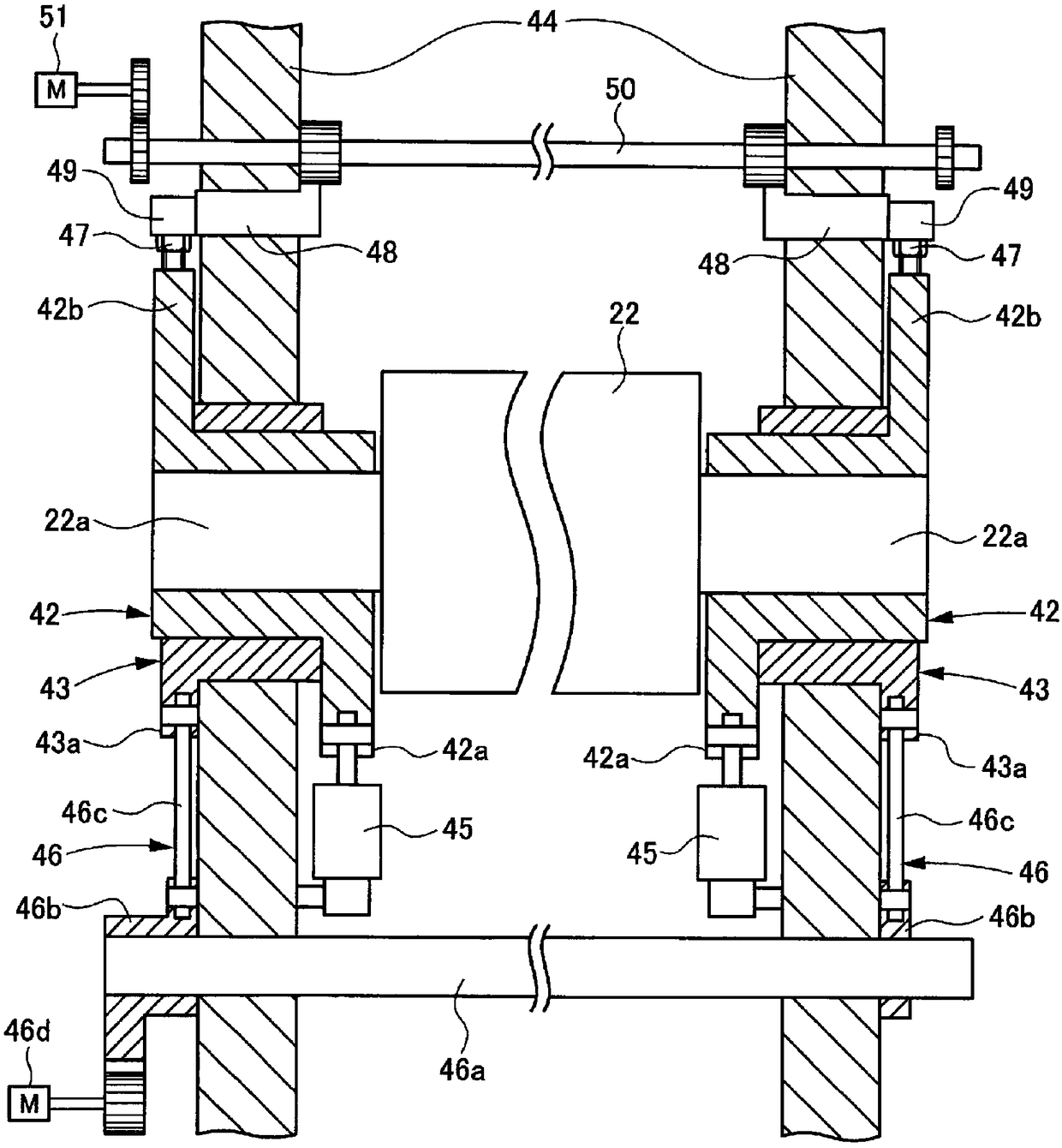

[0051] The multi-color pattern printing section 11 includes three partial printing cylinders 20 , a collective blanket cylinder 21 , a collective printing cylinder 22 , a blanket cylinder 19 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com