A connector for photovoltaic modules

A photovoltaic module and connector technology, which is applied to the support structure of photovoltaic modules, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of troublesome C-shaped steel wiring, large space occupied by springs, and reduced space of C-shaped steel, etc., to save space. , The effect of convenient mobile positioning and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

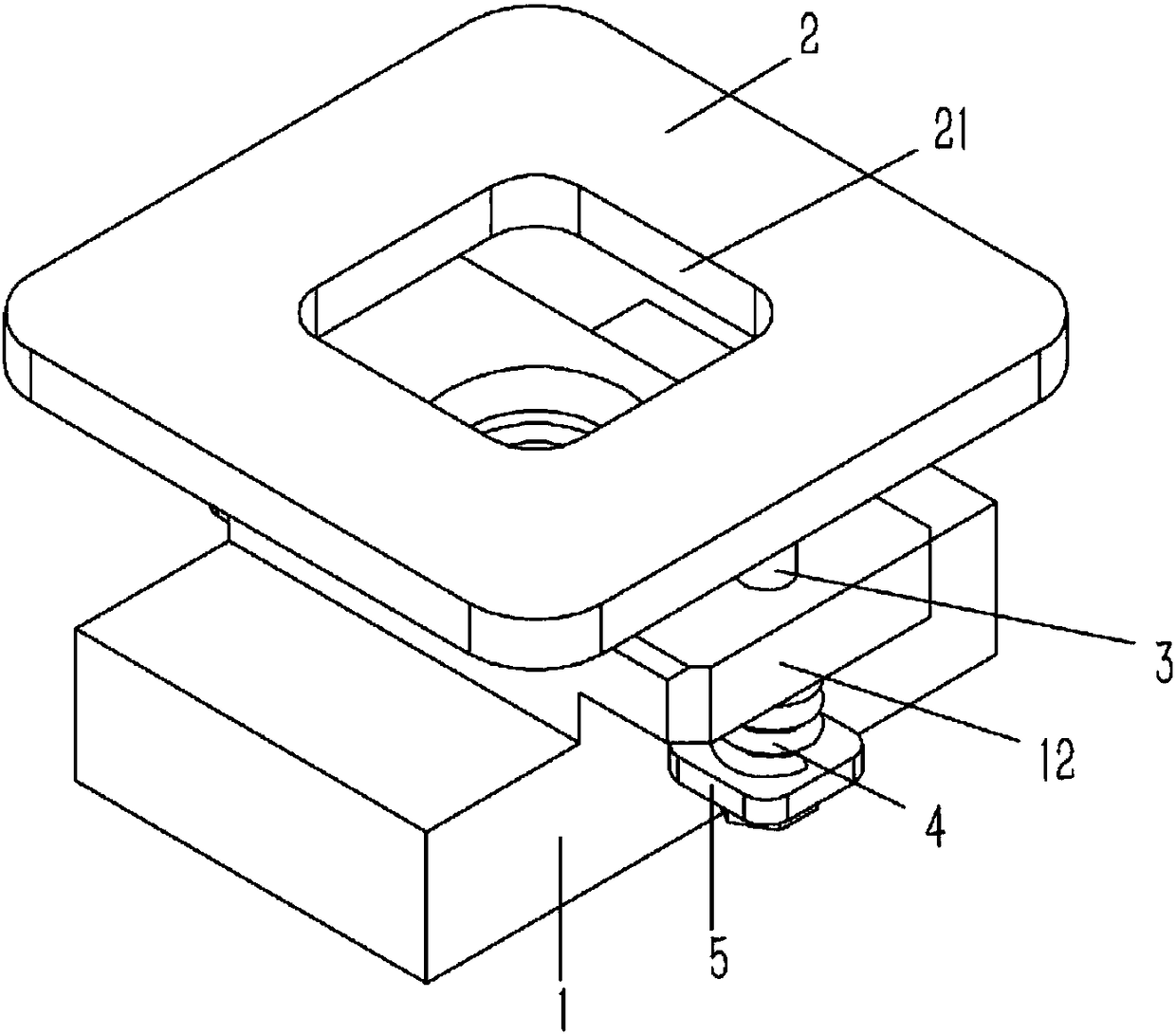

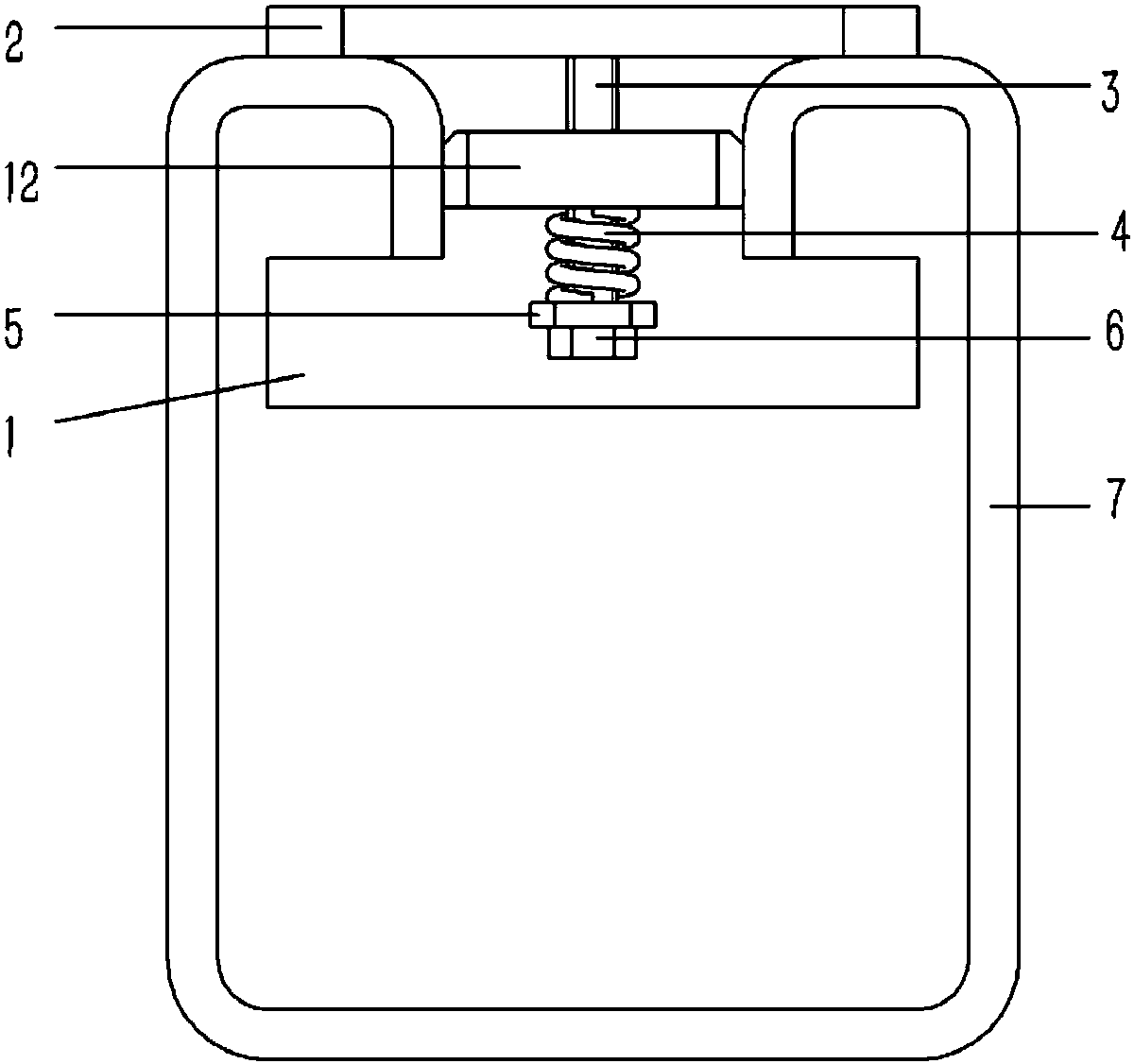

[0017] Example: see Figures 1 to 4 As shown, a connector for a photovoltaic module includes an inverted T-shaped block 1, the center of the upper end surface of the T-shaped block 1 is formed with a threaded hole 11 that runs through the lower end surface of the T-shaped block 1, and the front of the T-shaped block 1 1. Bosses 12 are formed on the side walls of the rear two sides, and vertical screw rods 3 are inserted on the bosses 12. The upper end of the screw rods 3 is fixed on the limit plate 2, and the limit plate just above the threaded hole 11 of the T-shaped block body 1 A via hole 21 is formed on the bit plate 2, and the lower end of the screw rod 3 passes through the boss 12 and is inserted into a compression spring 4 and a cushion block 5. The two ends of the compression spring 4 are pressed against the boss 12 and the cushion block 5 respectively, and the cushion The block 5 is pressed against the nut 6 which is screwed on the screw 3 .

[0018] The limiting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com