Arc Tubes for Single-Ended Ceramic Metal Halide Lamps

A ceramic metal and halide lamp technology, applied in the field of photoelectric power supply, can solve problems such as poor output parameters, and achieve the effect of improving load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the following, the present invention will be described in detail and specifically through specific examples, so as to better understand the present invention, but the following examples do not limit the scope of the present invention.

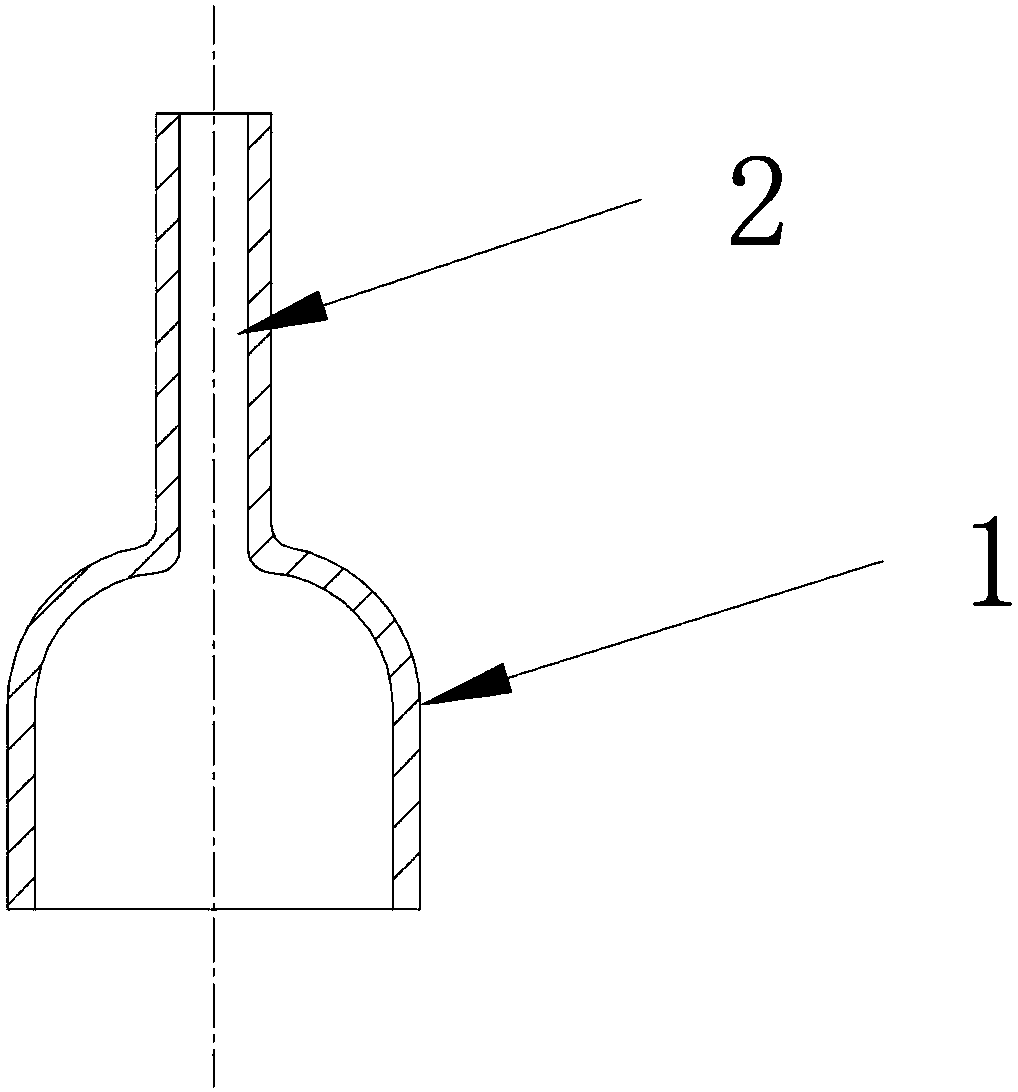

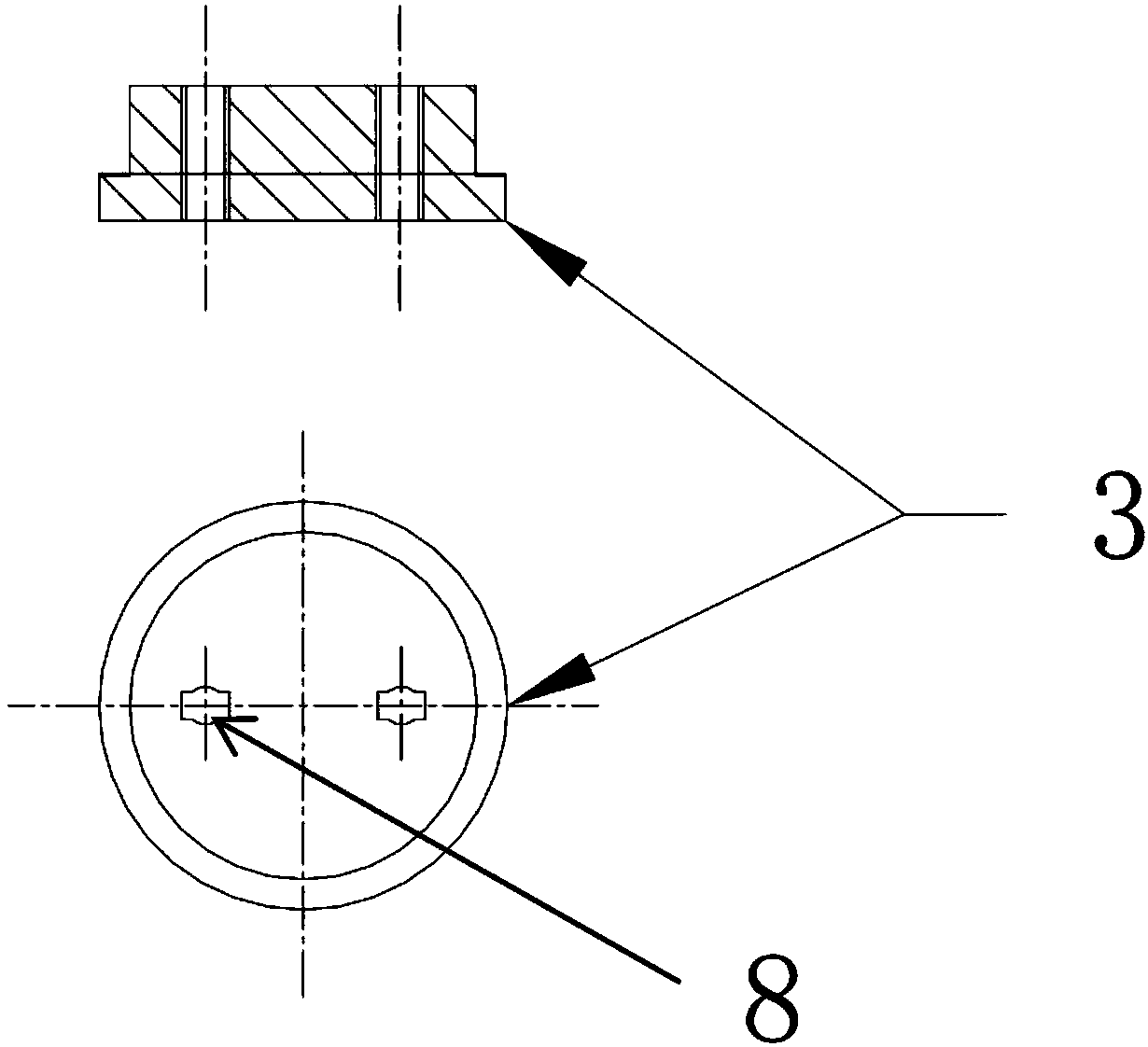

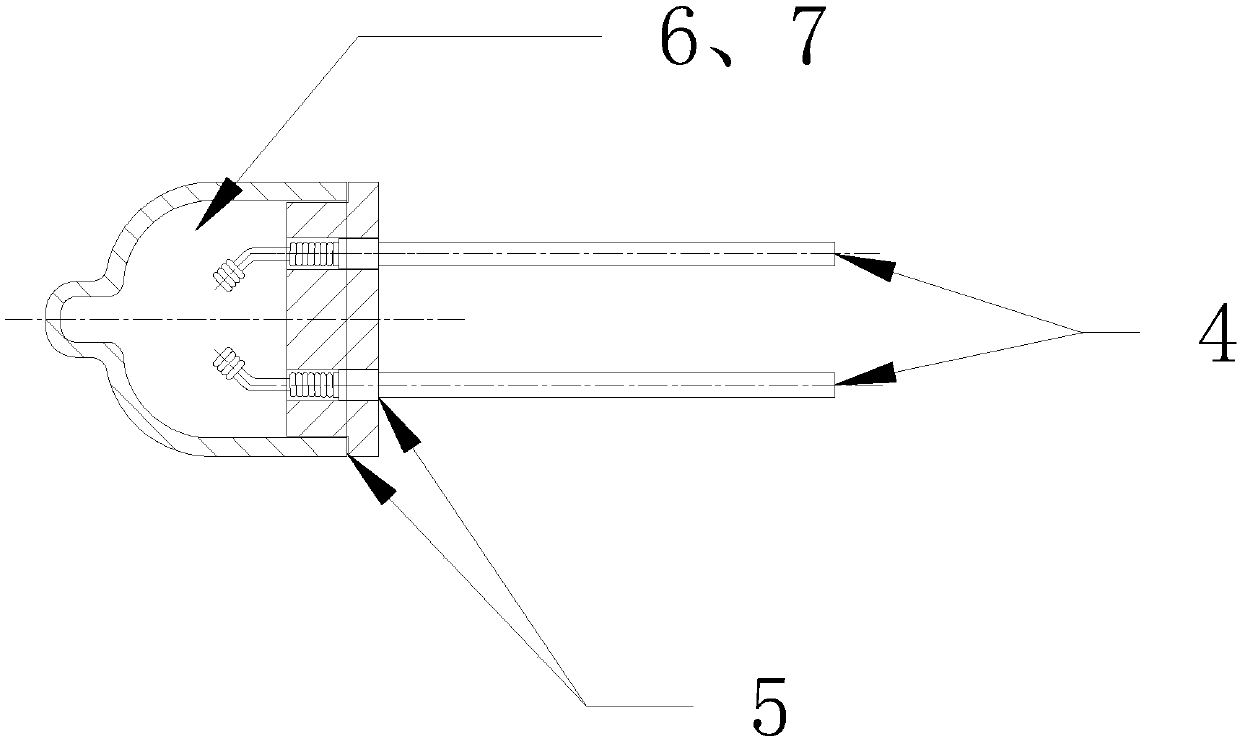

[0022] Such as Figure 1-3 As shown, this embodiment provides a single-ended ceramic metal halide lamp arc tube, which includes an open cavity 1, a capillary 2 arranged at the top of the hemisphere of the cavity 1, and a capillary 2 arranged at the opening of the cavity 1. Stepped ceramic plug 3, two emitter electrodes 4 are fixedly installed on the ceramic plug 3, and the cavity 1 is filled with halide, mercury 6 and starting gas 7 through the capillary 2.

[0023] The key point of the design of this embodiment is that two emitter electrodes 4 are arranged on the ceramic plug 3 on one end surface of the cavity body 1. The emitter electrode 4 is composed of an electrode and a porcelain tube. The distance between the two emitter electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com