Gauss sphere cluster based machine part reverse engineering modeling method

A technology of mechanical parts and reverse engineering, applied in the field of reverse engineering modeling of mechanical parts based on Gaussian spherical clustering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are schematic diagrams of actual operation, thereby showing the constitution related to the present invention.

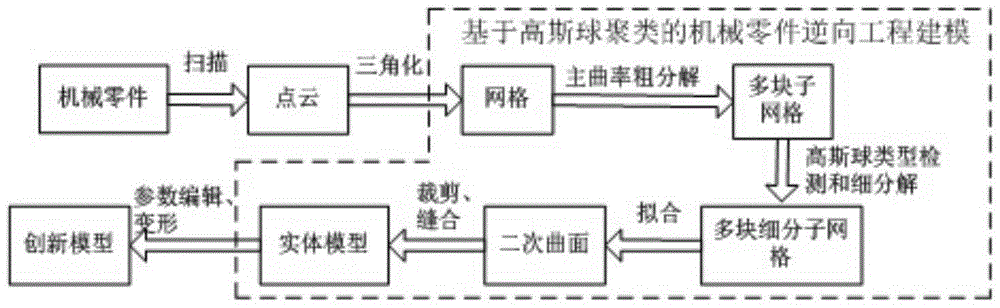

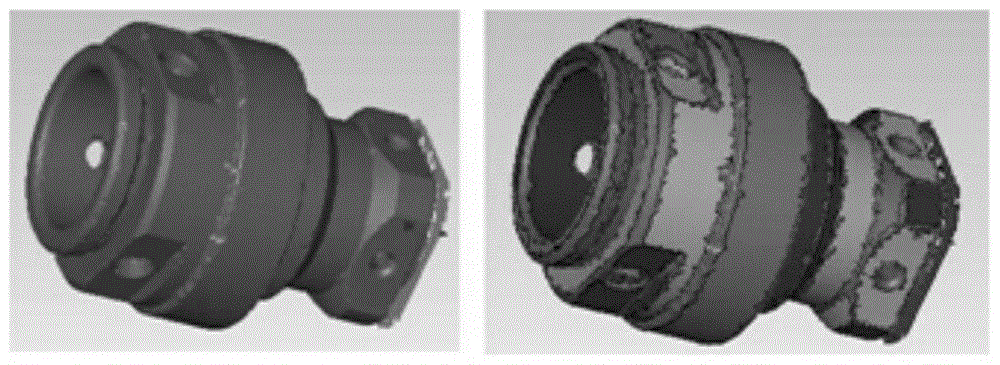

[0025] Such as figure 1 As shown, the present invention provides a method for reverse engineering modeling of mechanical parts based on Gaussian spherical clustering. The method flow is to scan the mechanical parts into a point cloud model using a laser three-dimensional scanner, and then use the triangulation method to convert the point cloud model into a point cloud model. It is automatically converted into a mesh model, and then coarsely decomposes the entire mesh using the discrete principal curvatures of the triangular faces. The grid is divided into several sub-grids; the goal is to make each quadratic surface in the part independently fall into the relevant sub-region, and then use the Gaussian spherical clustering method to perform type d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com