Rotating disk apparatus for wind tunnel jet pipe

A turntable and nozzle technology, applied in the direction of measuring devices, machine/structural parts testing, instruments, etc., can solve the problems of excessive load changes of the driving device, rolling body wear, etc., and achieve simple and reliable driving devices and uniform support force distribution , the effect of strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

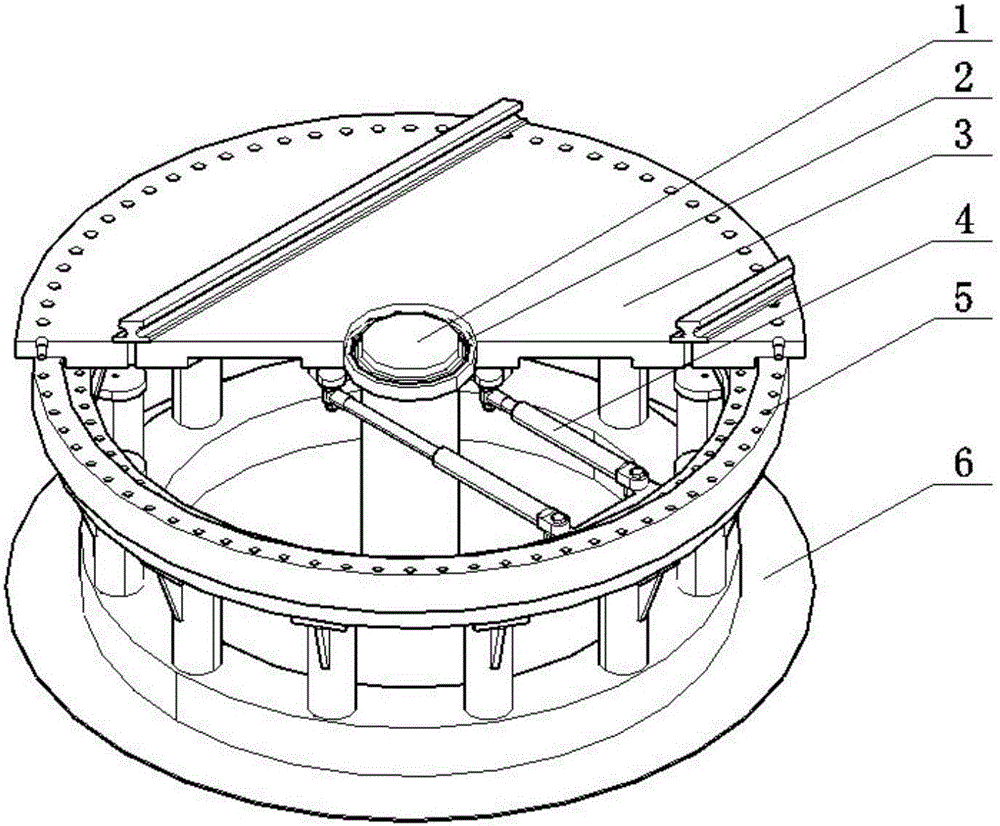

[0020] Such as figure 1 As shown, the present invention provides a turntable device for a wind tunnel nozzle, which features a central shaft 1, a central bearing 2, a turntable cover 3, a hydraulic cylinder 4, a slewing support bearing 5, and a base 6;

[0021] The central shaft 1 is fixed on the foundation and does not move. The central bearing 2 and the slewing support bearing 5 both rotate with the central shaft 1 as the center of rotation. The central bearing 2 adopts a deep groove ball bearing, the inner ring of which is sleeved on the central shaft 1, and the outer ring Embedded on the turntable cover 3, it mainly plays the role of central positioning and bearing part of the overturning moment; the slewing ring bearing 5 adopts a three-row roller type slewing ring bearing, the inner ring is connected with the turntable cover 3, and the outer ring is fixed on the foundation. The base 6 is connected to mainly bear the vertical weight load on the turntable cover 3 and most ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com