Implementation method of automatic gyro drift compensation of two-axis four-frame photoelectric pod

A photoelectric pod and gyro drifting technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of long time consumption, poor compensation accuracy, and cost, and achieve the effect of fast compensation speed and high compensation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

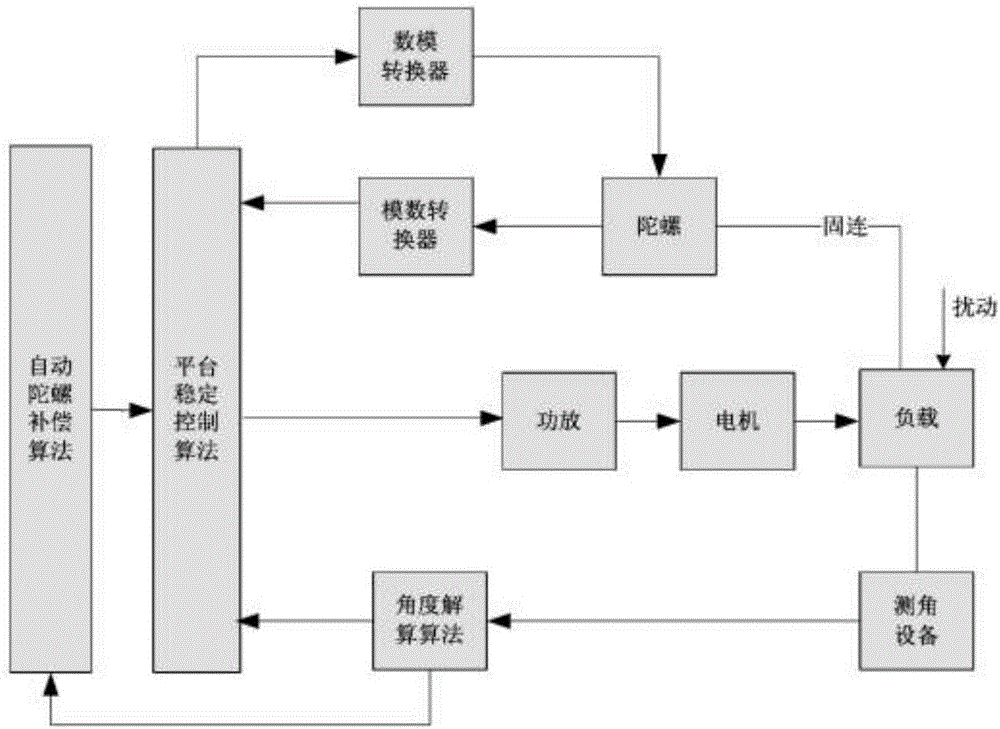

[0020] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

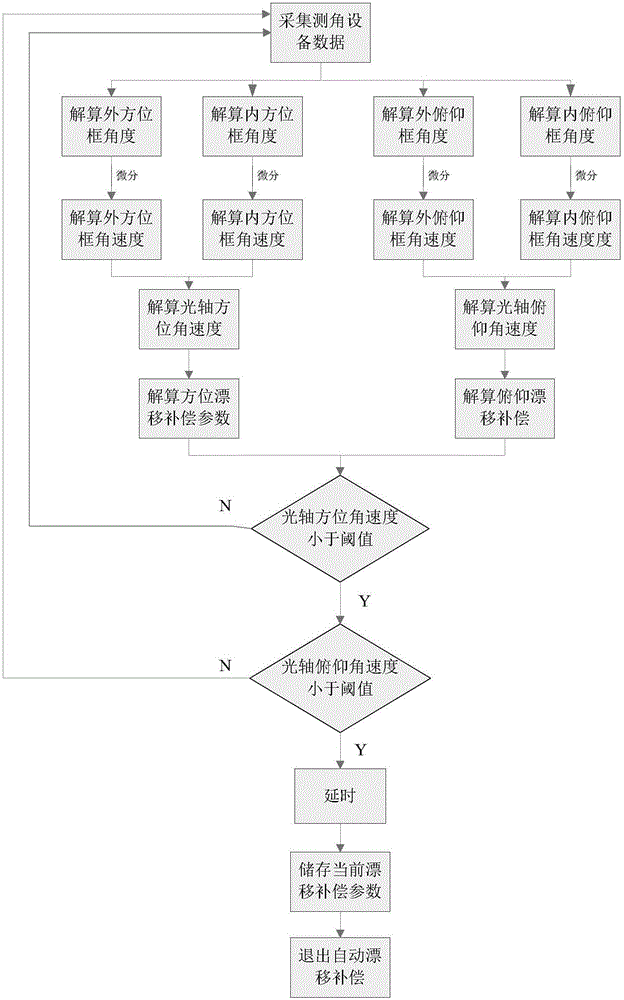

[0021] The two-axis four-frame photoelectric pod has two frames, the outer frame and the inner frame, on each axis of the azimuth and pitch. After the photoelectric pod is started and self-inspected, the pod is kept still. At this time, the angle measuring equipment is continuously collected. The angles of the outer frame and the inner frame on the two axes of azimuth and pitch are calculated by differentially calculating the angular velocity of the outer frame of the pod relative to the pod on the two axis systems.

[0022] Let the angular velocity of the pod relative to the inertial space on a shaft system be ω pod , the angular velocity of the outer frame of the pod relative to the pod is ω o , the angular velocity of the inner frame of the pod relative to the pod is ω i , the angular velocity of the pod optical axis on the corresponding shaft system is ω a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com