Workpiece multi-dimension multi-parameter measuring method based on image processing

A measurement method and image processing technology, applied in measurement devices, instruments, optical devices, etc., can solve the problem of not many measurement platforms, and achieve the effect of saving measurement time, ensuring measurement accuracy, and reducing measurement difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

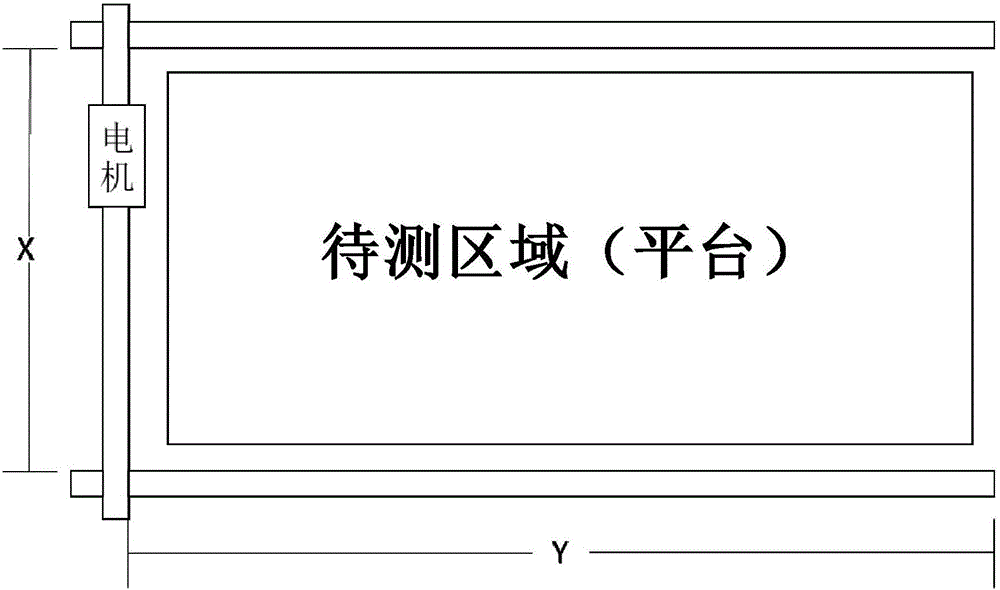

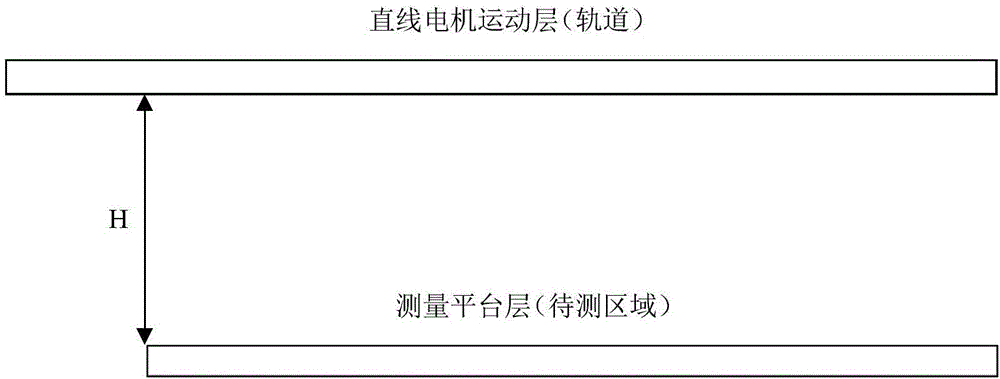

[0035] Embodiment 1 measuring method:

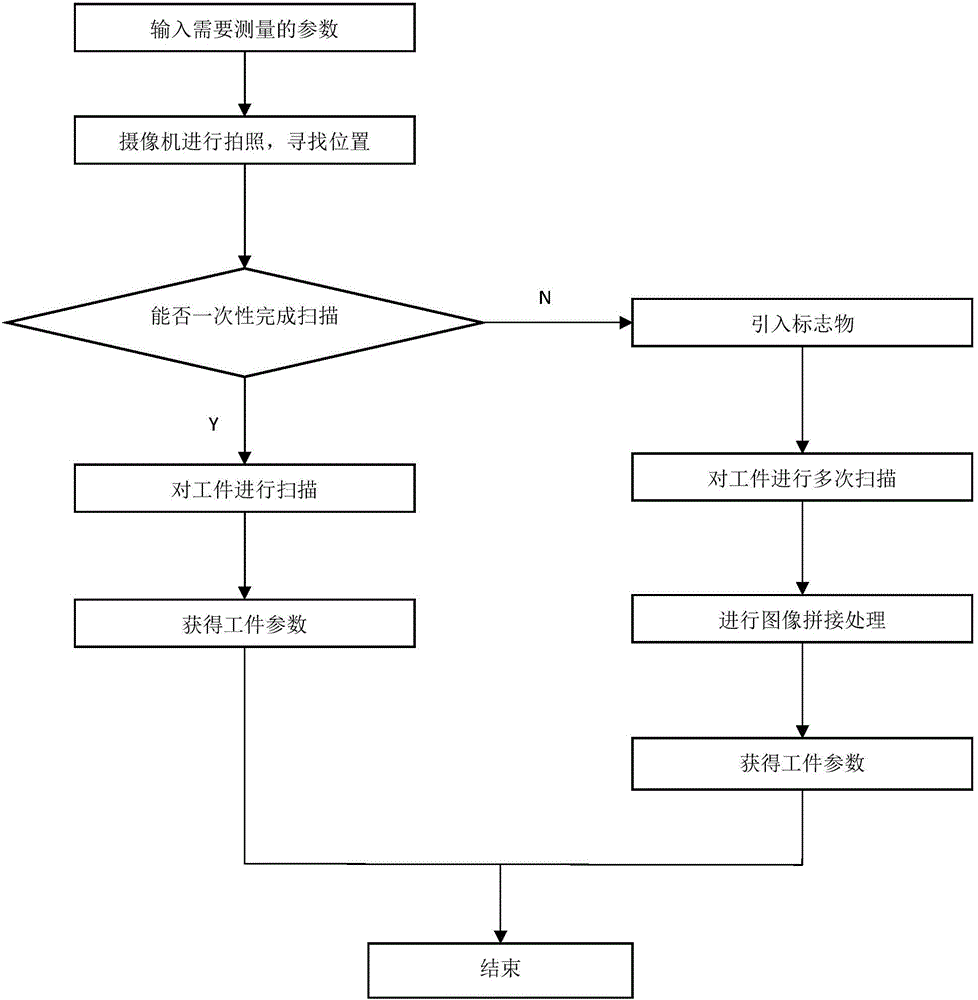

[0036] In some cases, it is necessary to use laser scanning to obtain workpiece parameters, then use such as diagram 2-1 The process of measuring workpieces includes the following steps:

[0037] Step 1. Input the workpiece parameters to be measured. The workpiece parameters include workpiece size, hole diameter, center distance of the hole, etc.;

[0038] Step 2: Fix the industrial measurement camera to shoot the workpiece, and use the scale calibration of the platform in the area to be measured to estimate the size and position of the workpiece;

[0039] Step 3. Through the relationship between the estimated length of the workpiece in the X-axis direction and the single scanning width of the laser scanner, it is judged whether the workpiece can be scanned once;

[0040] Step 4. If the workpiece can be scanned once, move the motor to the corresponding position, scan the workpiece with a laser scanner, process the point cloud data obt...

Embodiment 2

[0043] Embodiment 2 measuring method:

[0044] In some cases, it is necessary to take pictures to obtain workpiece parameters, for example: the image parameter information of the workpiece surface is required or only unilateral workpiece surface information is required, then use such as Figure 2-2 The process of measuring workpieces includes the following steps:

[0045] Step 1. Input the surface parameter information of the workpiece to be measured;

[0046] Step 2: Fix the industrial measurement camera to shoot the workpiece, and use the scale calibration of the platform in the area to be measured to estimate the size and position of the workpiece;

[0047] Step 3. According to the estimated size of the workpiece, determine whether the industrial measuring camera installed on the motor can obtain the surface image of the workpiece at one time;

[0048] Step 4. If the surface image of the workpiece can be captured by the industrial measuring camera once, the linear motor m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com