Warhead dismantling device and method

A warhead and power device technology, applied in the direction of ammunition, weapon accessories, offensive equipment, etc., can solve the problems that the steel bullet core, armor and lead sleeve cannot be effectively separated, the recycling rate of materials is low, and the economic benefit is poor. Achieve the effects of convenient sorting and recycling, low manufacturing cost, and convenient maintenance in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

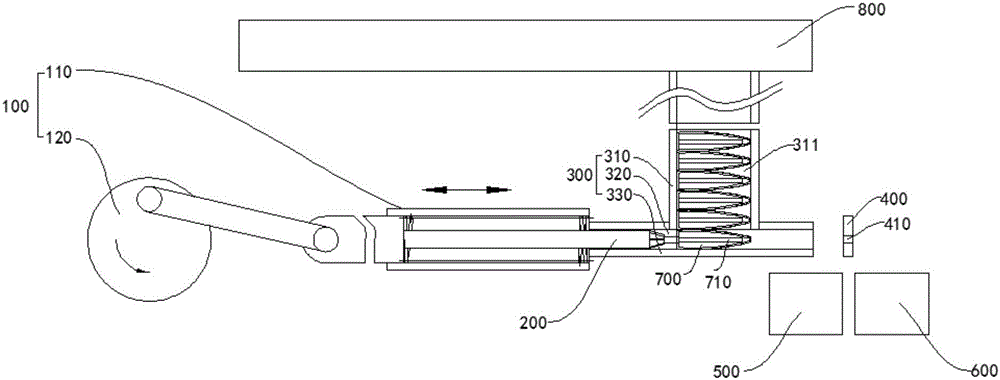

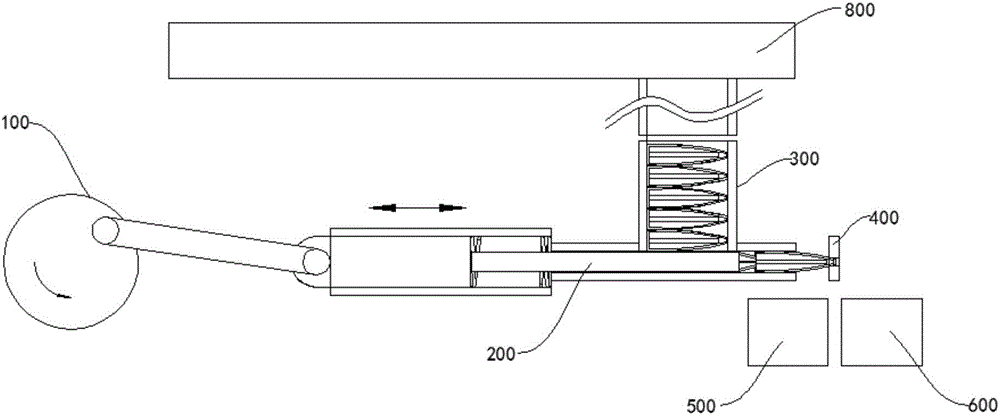

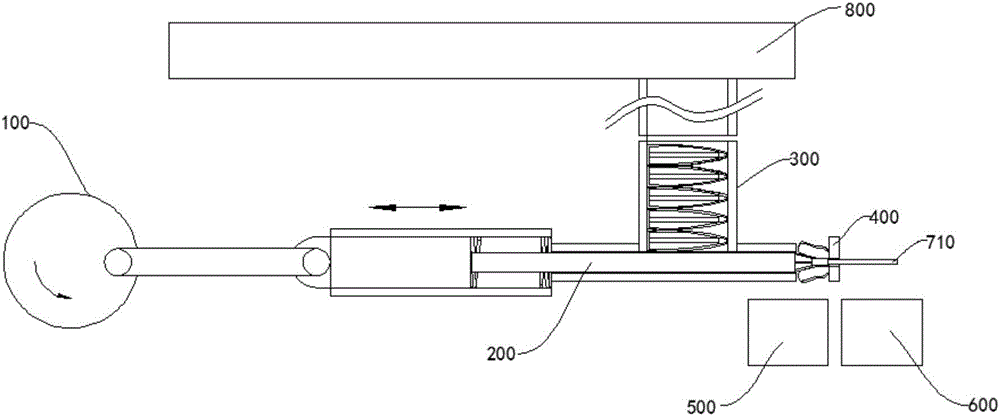

[0036] Such as figure 1 , figure 2 , image 3 As shown, a warhead dismantling device includes a power unit 100, an armor-piercing knife 200, a bullet holder 300, and a cutting knife 400; in this embodiment, the armor-piercing knife 200 uses a three-edged knife or a four-edged knife, This can effectively puncture the armor of the warhead, and at the same time, the armor can be separated into multiple pieces, which facilitates the separation of the first separator in the later stage; Side; cutting knife 400 is less than the length of bullet 700 apart from the shortest distance of holder bullet holder 300; The diameter of the hole 410 is smaller than the diameter of the warhead 700. The inner hole 410 has three fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com