Heat source tower liquid distribution device with variable flow self-adaptive function

An adaptive, heat source tower technology, applied in the field of heat source towers, can solve the problems of fixed design flow, simple structure, cumbersome disassembly and replacement, etc., and achieve the effect that the uniformity of liquid distribution is basically unchanged, the replacement is simple and easy, and the overall structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the specific embodiments and the accompanying drawings.

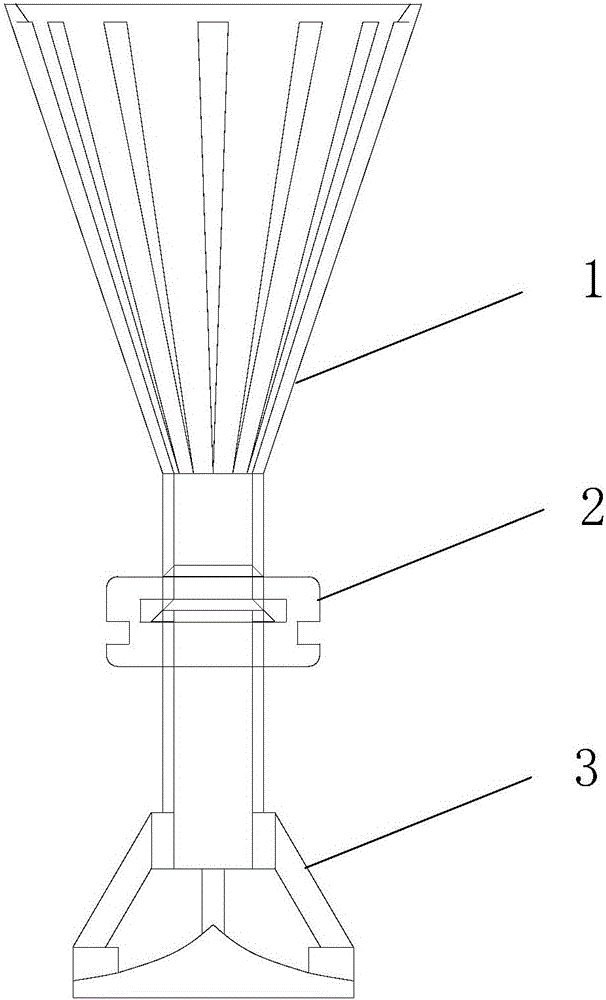

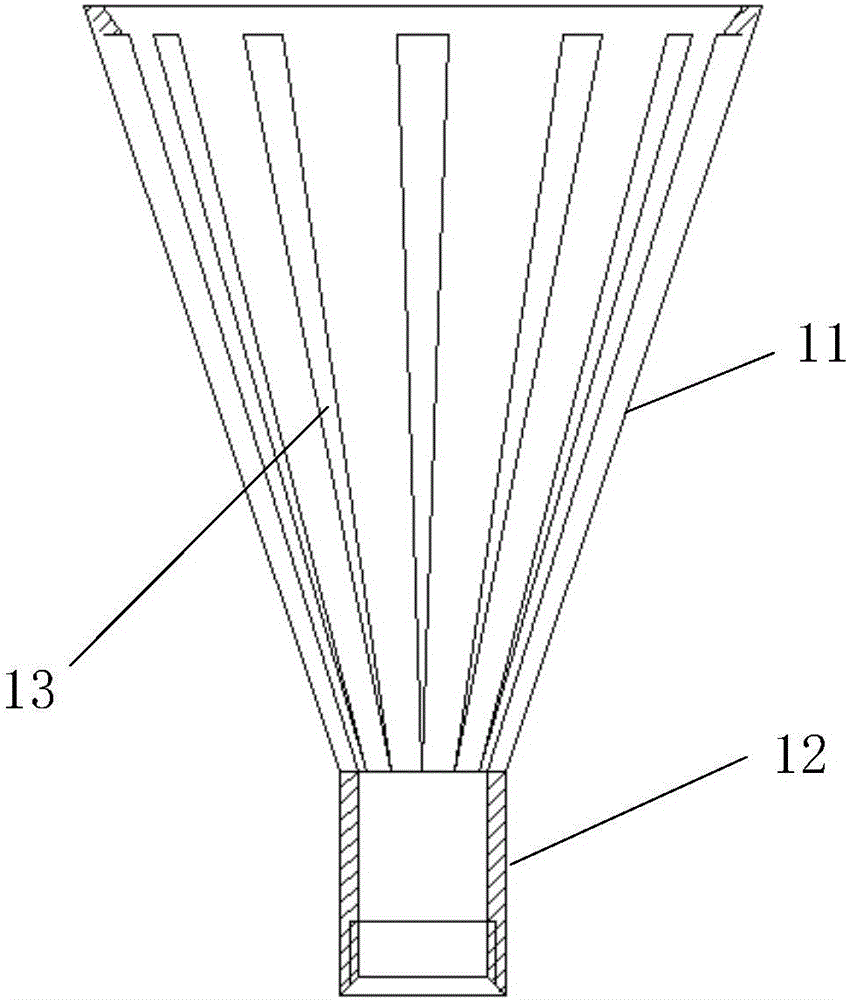

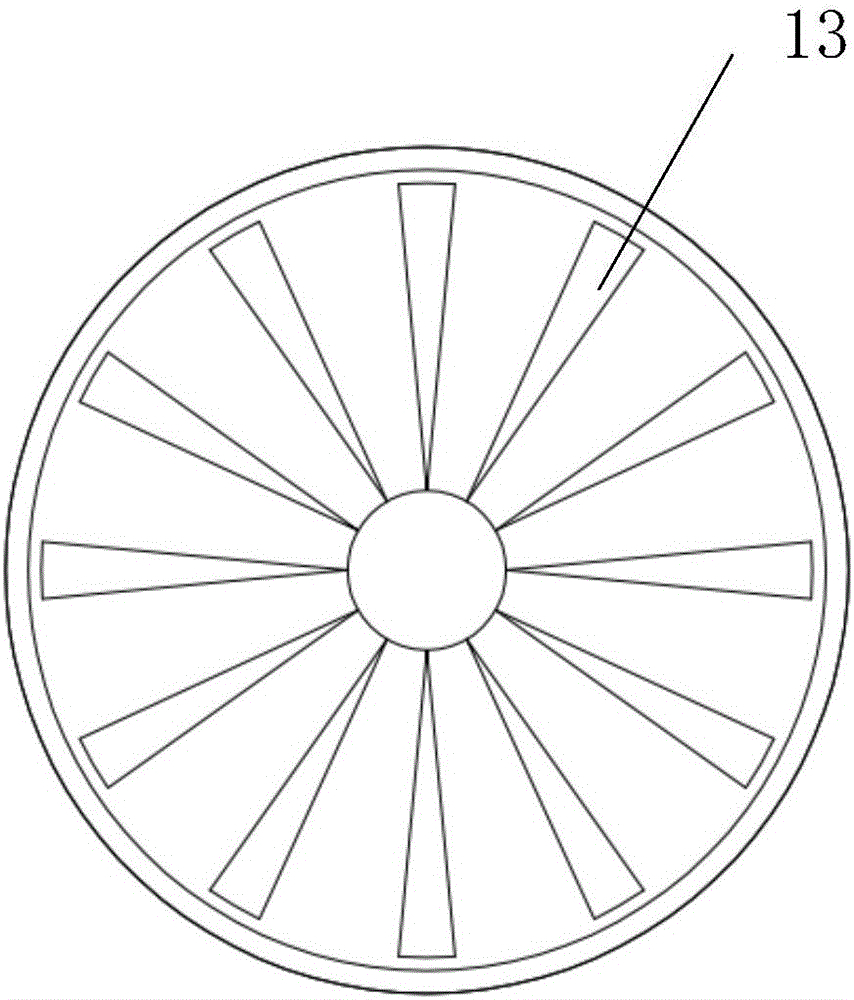

[0023] The heat source tabby liquid device with variable flow self-adaptive function of the present invention includes three parts: a funnel 1 , an apron 2 and a nozzle 3 . The funnel 1 includes a bucket body 11 and a lower tube 12, and an internal thread is arranged inside the lower tube 12; an annular groove 21 is arranged inside the apron 2, and an annular groove 22 is arranged outside; the nozzle 3 includes a splash tube 31, a support frame 32, and a splash plate 33. The splash tube 31 is provided with external threads and shoulders, the top of the support frame 32 is connected with the splash tube 31, and the bottom end is connected with the splash plate 33; the funnel 1 and the nozzle 3 are fixed by threaded connection, the apron 2 and the nozzle 3. Fix by inserting the card shoulder into the annular groove. The bucket body 11 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com