Novel wood chip dryer

A technology of dryer and sawdust, applied in dryer, drying, wood particle drying and other directions, can solve problems such as short drying time, low heat exchange efficiency, dryer explosion, etc., and achieve controllable drying temperature , The effect of uniform quality of wood chips and uniform drying temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

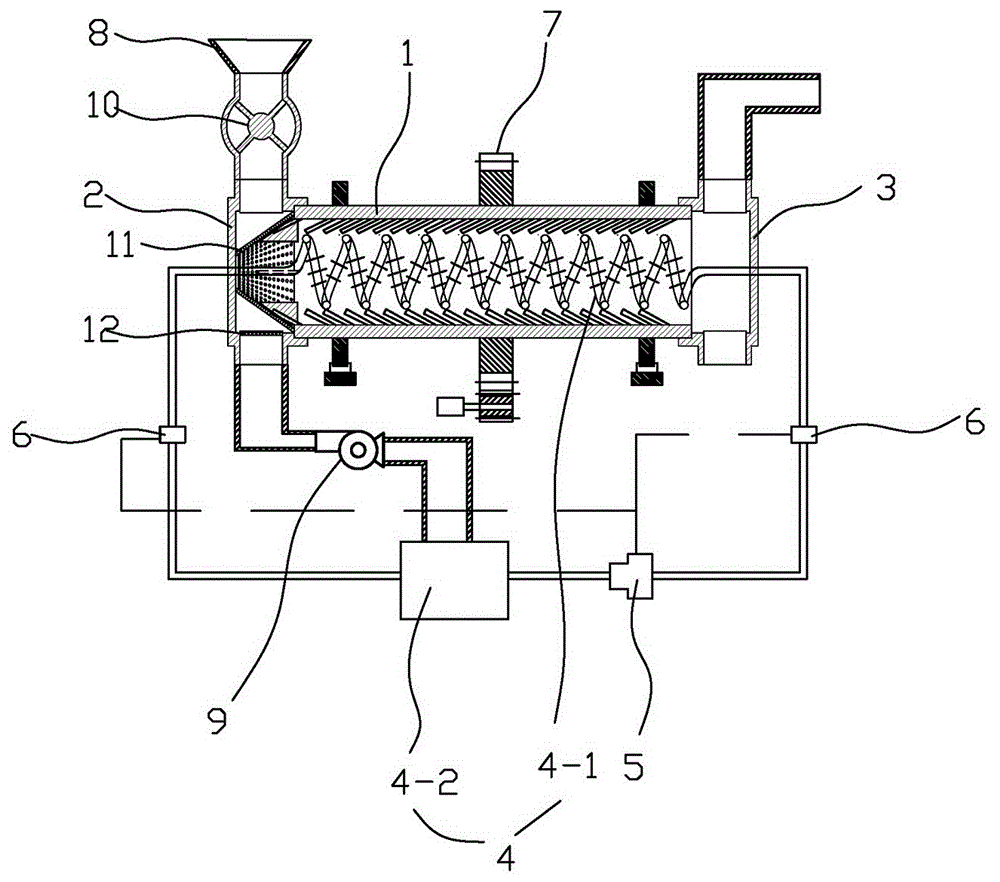

[0035] Example 1: Reference figure 1 , a new type of sawdust dryer, including a drum 1 with heat preservation function, a left end cover 2 sleeved on the left end of the drum, a right end cover 3 sleeved on the right end of the drum, and a rotating mechanism 7 that drives the drum to rotate, and also includes Circulating heating device 4, said circulating heating device 4 includes a heat pipe 4-1 arranged inside the drum 1 and a heat supply device 4-2 connected to both ends of the heat pipe 4-1, and the heat supply device 4-2 is connected to the heat pipe 4-1. A circulation loop is formed between the heat conduction pipes 4-1, and the circulation loop is filled with a heat-conducting medium, and a circulating electric pump 5 is provided on the circulation loop, and the circulating electric pump 5 drives the heat-conducting medium to circulate in the circulation loop.

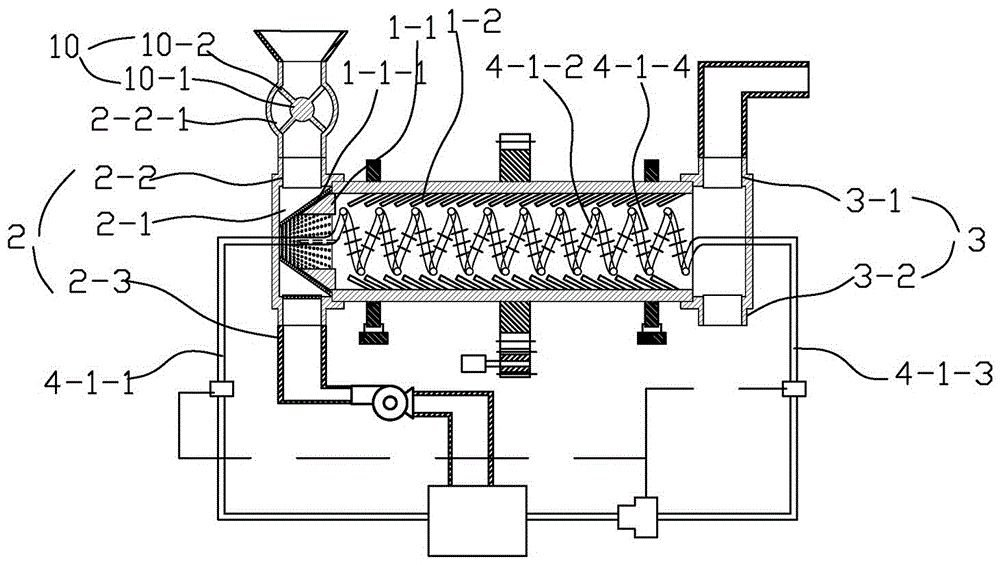

[0036] refer to figure 2, the heat pipe 4-1 sequentially includes a heat conduction medium feeding section ...

Embodiment 2

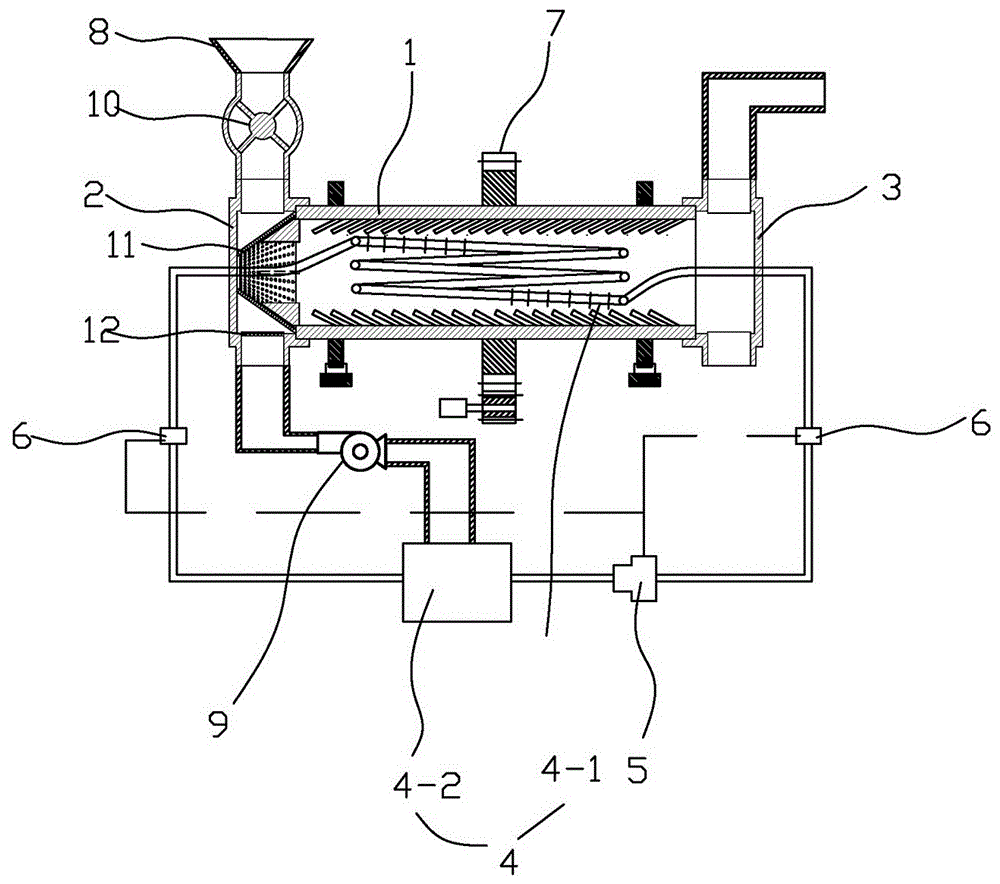

[0047] Example 2: Reference image 3 , this embodiment is basically the same as the embodiment, the only difference is: the spiral coil and the drum 1 are vertically arranged.

[0048] During work, the screened materials are discharged from the feed channel 2-2 to the storage chamber 2-2-1, and the material shifting mechanism 10 in the storage chamber 2-2-1 dials the materials into the left end cover 2. In the blanking chamber 2-1, the air supply device 9 blows the filtered hot air from the chimney of the heating device 4-2 boiler into the blanking chamber 2-1 from the air inlet channel 2-3 at the same time, and the material is During the process, the distributing part 11 screens and separates them, and the larger diameter and heavier materials fall on the spacer mesh 12 under the distributing part 11, while the smaller and lighter materials fall under the action of hot air. Carry out pre-drying and screening, because drum 1 rotates under the effect of rotating mechanism 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com