Pipeline system three-way active/passive vibration absorbing ring

A pipeline system, active and passive technology, applied in the direction of pipe components, shock absorbers, vibration suppression adjustment, etc., can solve the problems of limited vibration suppression effect and unsatisfactory vibration suppression, and achieve easy disassembly and installation, fast response speed, and control Mode flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

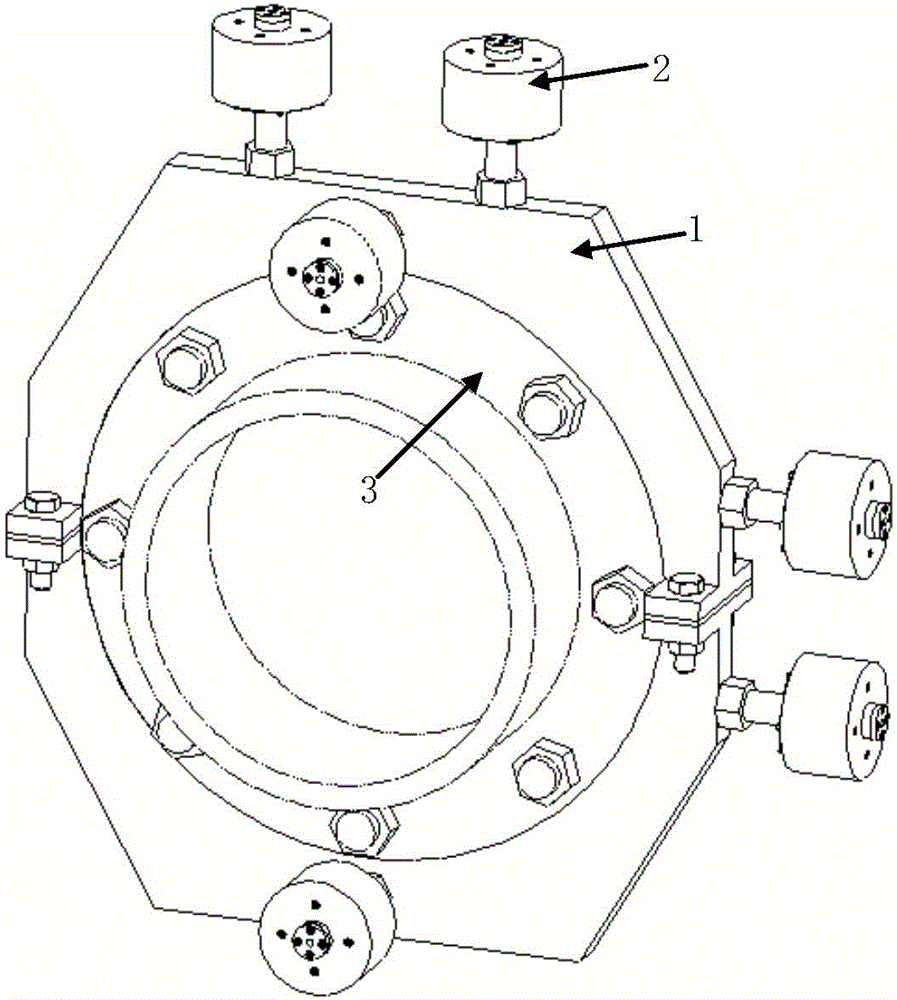

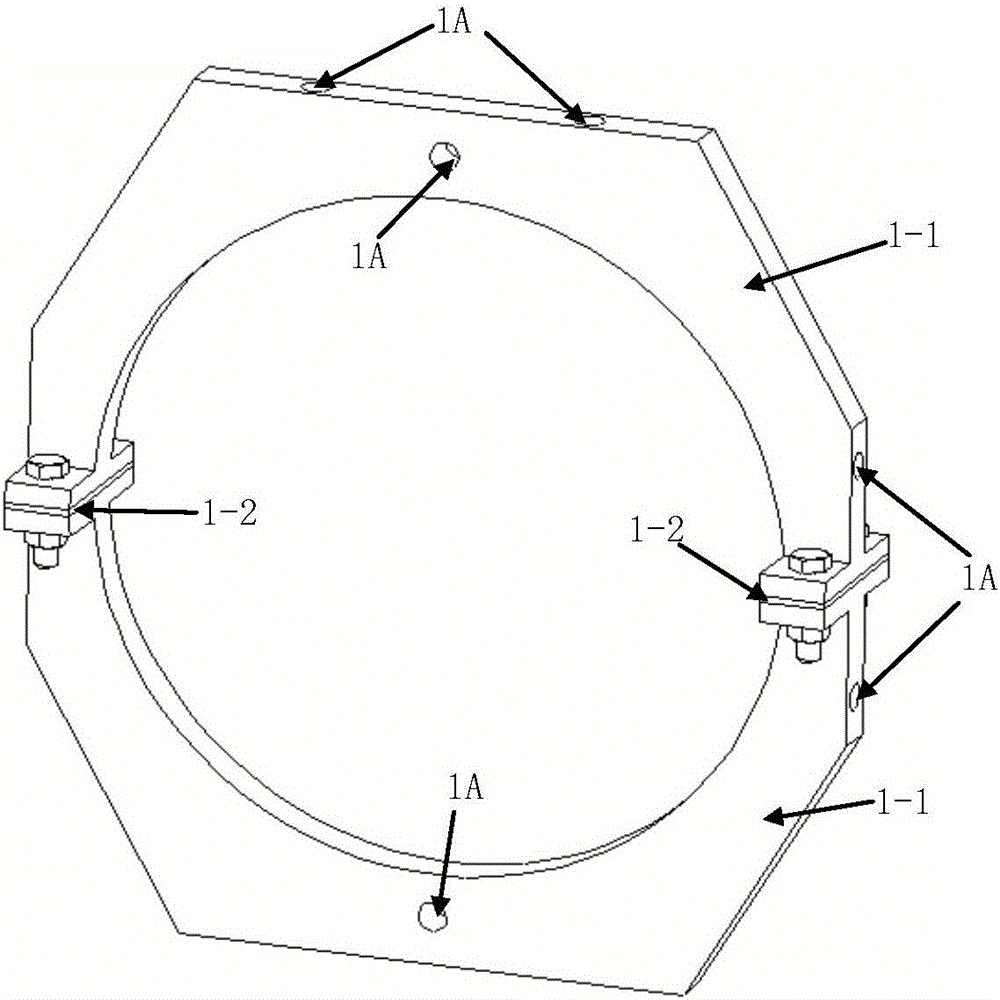

[0019] Referring to the accompanying drawings, a three-way active and passive vibration absorbing ring of a pipeline system includes: an annular clamp 1, and six single-degree-of-freedom active and passive dynamic vibration absorbers 2;

[0020] The ring clamp 1 is made of stainless steel and consists of two half clamps 1-1, with a hexagonal or other polygonal structure; the two sides of the two half clamps 1-1 are connected together by two bolts, and the There are adjustable rubber pads 1-2; the upper end face, the right end face and the front end face of the ring clamp 1 are respectively provided with two symmetrically distributed threaded holes 1A, which are used to connect the single-degree-of-freedom active and passive dynamic shock absorber 2;

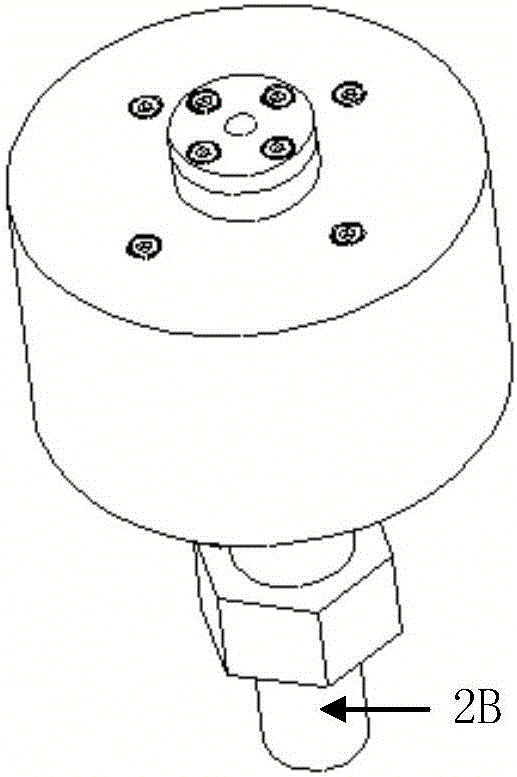

[0021] Single degree of freedom active and passive dynamic vibration absorber 2 includes: permanent magnet 2-1, housing 2-2, linear bearing 2-3, end cover 2-4, diaphragm spring 2-5, coil sleeve 2-6, guide rod 2-7, threaded connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com