Mining centrifugal pump on-line accelerated life test platform and test method thereof

An accelerated life test, centrifugal pump technology, applied in pump control, non-variable-capacity pumps, machines/engines, etc., can solve problems such as failure to fully reflect fault characteristics, few equipment monitoring parameters, and discrete artificial fault points. Improve the efficiency of test work, reduce work intensity, and ensure the effect of accuracy

Inactive Publication Date: 2017-02-22

TAIYUAN UNIV OF TECH

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, at present, the failure data of centrifugal pumps is not comprehensive. Most of the centrifugal pump failures develop rapidly, and the monitoring parameters of equipment on the job site are few and cannot fully refl

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Login to View More

Abstract

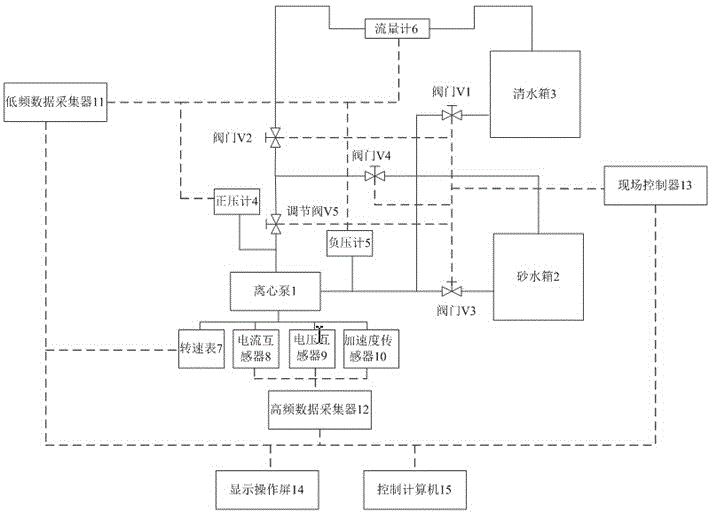

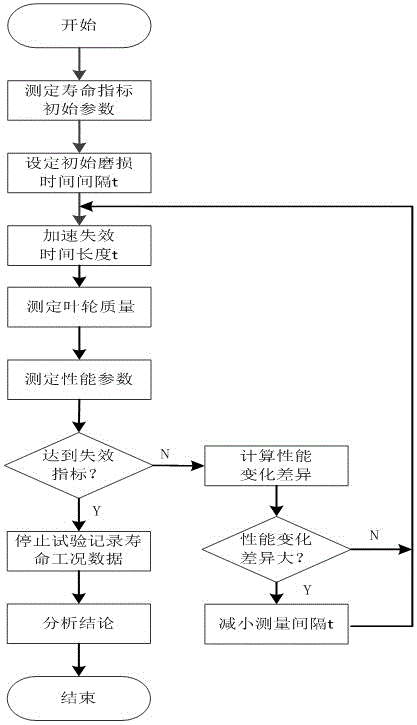

The invention discloses a mining centrifugal pump on-line accelerated life test platform and a test method thereof. The mining centrifugal pump on-line accelerated life test platform is in a double-circulation measurement isolation pipeline structure, comprises a centrifugal pump accelerated life circulation pipeline and a centrifugal pump health performance measurement pipeline, and consists of a system structure combing a field monitoring and controlling system and a control computer remote monitoring system. With the adoption of the test method, a centrifugal pump accelerated life test accomplished automatically, and centrifugal pump characteristic curves are drawn remotely and centrifugal pump health life information is stored. Monitoring parameters are comprehensive, the structure is reasonable, full life cycle data of a centrifugal pump in a failure process can be monitored effectively, other components like a sensor and a pipeline are protected from being eroded, and the foundation for acquiring centrifugal pump accelerated life data is laid.

Description

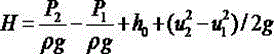

technical field [0001] The invention relates to an online centrifugal pump test platform and a test method thereof, in particular to a centrifugal pump accelerated life test platform for online measurement and a test method thereof. Background technique [0002] Centrifugal pump is a kind of rotating mechanical equipment widely used in industrial drainage, and it plays an important role in many industries such as electric power, mining, chemical industry, and agriculture. When the centrifugal pump transports the fluid medium, due to the erosion of the particles and impurities in the medium, the blades of the centrifugal pump will wear to a certain extent, which will eventually lead to the failure of the centrifugal pump. In order to reduce the economic losses and potential safety hazards caused by unexpected failure of centrifugal pumps, it is necessary to establish a condition-based maintenance system for centrifugal pumps. The basis for realizing condition-based maintenan...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F04D15/00

CPCF04D15/0088

Inventor 宋建成田慕琴姚宇郭文琪郑丽君

Owner TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com