Whole-process leakage-plugging and well-cementing design method for high-temperature and high-pressure ultra-deep well

A high-temperature, high-pressure, ultra-deep well technology, applied in wellbore/well components, design optimization/simulation, calculation, etc., can solve problems such as leakage, adverse effects of cementing operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] Embodiments of the present invention will be described in detail below in conjunction with examples.

[0082] Taking the 206.38mm liner cementing of a gas well as an example, the construction parameters of plug flow cementing are calculated:

[0083] A. According to the circulation displacement of 16L / s during well drilling, the formation pressure bearing capacity is calculated to be 7.45MPa;

[0084] B. According to the pressure bearing capacity, drilling fluid performance and liner string structure calculated in step A, the maximum liner string lowering speed is calculated to be no more than 0.195m / s, and the liner string is lowered according to the calculated speed;

[0085] C. After running the casing, calculate the circulating displacement of 14L / s according to the pressure bearing capacity, drilling fluid performance and annular space calculated in step A, and circulate the drilling fluid according to the calculated displacement;

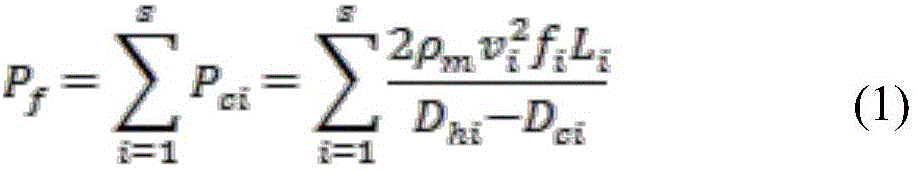

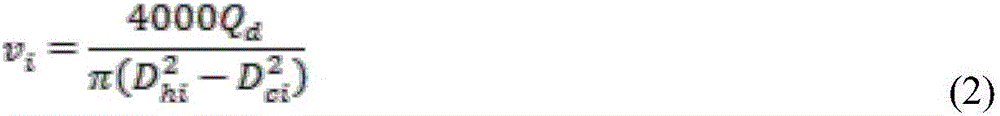

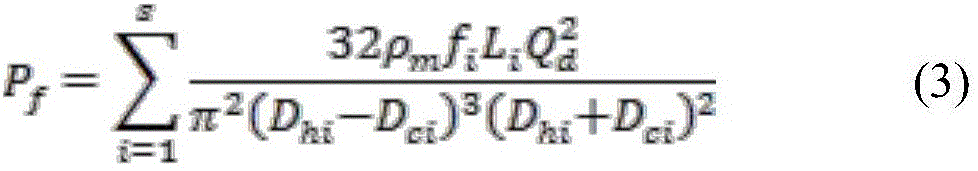

[0086] D. Calculate the plug fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com