Drilling-free hierarchical cementing method and cementing device

A step-by-step cementing device and a step-by-step cementing technology, which are applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., can solve the problem that the rubber plug cannot fall freely to the bottom of the well smoothly, and electrical testing of well completion cannot be performed Operation, unable to effectively clean casing cement block and other problems, to achieve the effect of simple and easy manufacturing and processing, strong stability and reliability, and economical manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

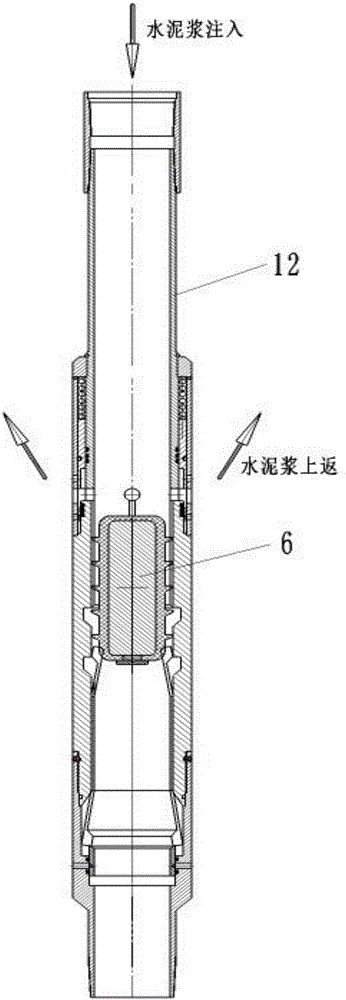

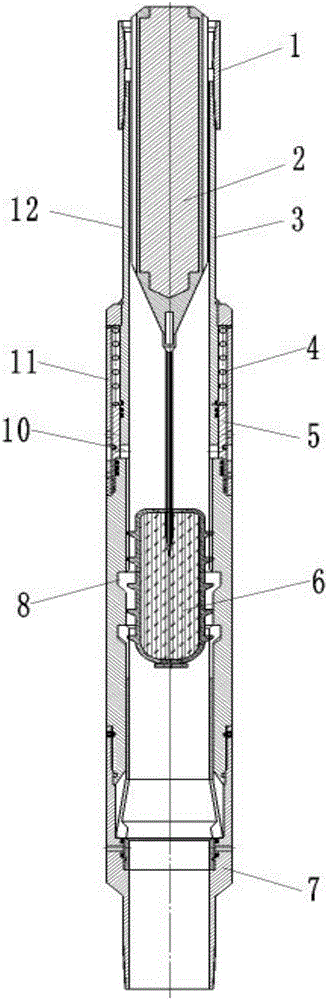

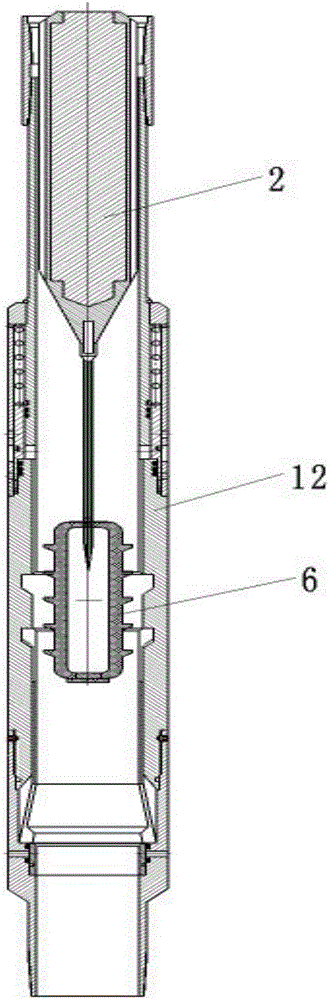

[0024] Embodiments of the present invention: the structural representation of the drill-free graded cementing device of the present invention is as follows Figure 1~3 As shown, it is composed of a full-bore differential pressure grading hoop 12, a rubber plug 6 and a gravity hammer 2. The full-bore differential pressure grading hoop 12 includes a casing 3 and upper ends connected to both ends of the casing 3. The coupling 1 and the lower coupling 7 are respectively provided with a grouting hole 10 and an annular clamping groove 8 on the inner wall of the casing 3 from top to bottom, and a pressure difference is set at the position of the grouting hole 10 on the outer wall of the casing 3 The sleeve 11 is provided with a sealing sleeve 5 that can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com