A kind of integrally formed aluminum electrolytic cell anode composite covering layer and method

An integral forming, aluminum electrolytic cell technology, applied in the field of aluminum electrolysis, can solve the problems of dissatisfaction, difficulty in recruiting and retaining electrolytic workers, etc., to reduce the load of the crane, reduce the probability of pollution, and reduce the cycle cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

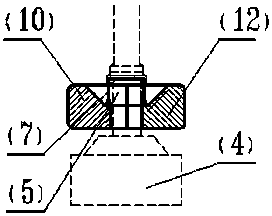

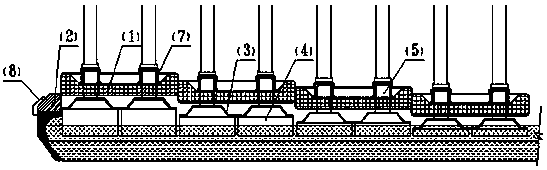

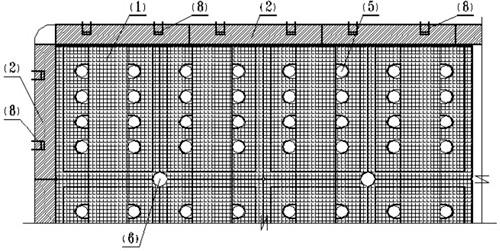

[0064] The existing aluminum electrolysis electrolyte and alumina mixed covering material layer methods are as follows: figure 2 , the anode cover material layer 9 is covered on the anode 4; the present invention provides a composite cover layer of an aluminum electrolytic anode that is integrally formed and can be reused many times, such as figure 1 , which can meet the requirements of heat preservation, gas collection and anti-oxidation of the traditional covering material layer, and can reduce the circulation and processing capacity of the covering material system; it can reduce the process and flow of covering material circulation, and reduce the cycle cost; it can reduce the cost caused by the pole change operation Fluctuations in the tank conditions can improve the operation stability; it can avoid the heat loss of the residual pole covering material and the heat expenditure of the new pole covering material; it can reduce the pole change process of the crane and shorten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com