Filter element backwashing device

A technology of backwashing and filter elements, which is applied to special treatment targets, water/sewage treatment, osmosis/dialysis water/sewage treatment, etc. It can solve problems such as short life, inability to flush micropores, and no effect of ultrafiltration membrane life extension. Achieve the effect of saving cost, prolonging service life and improving life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

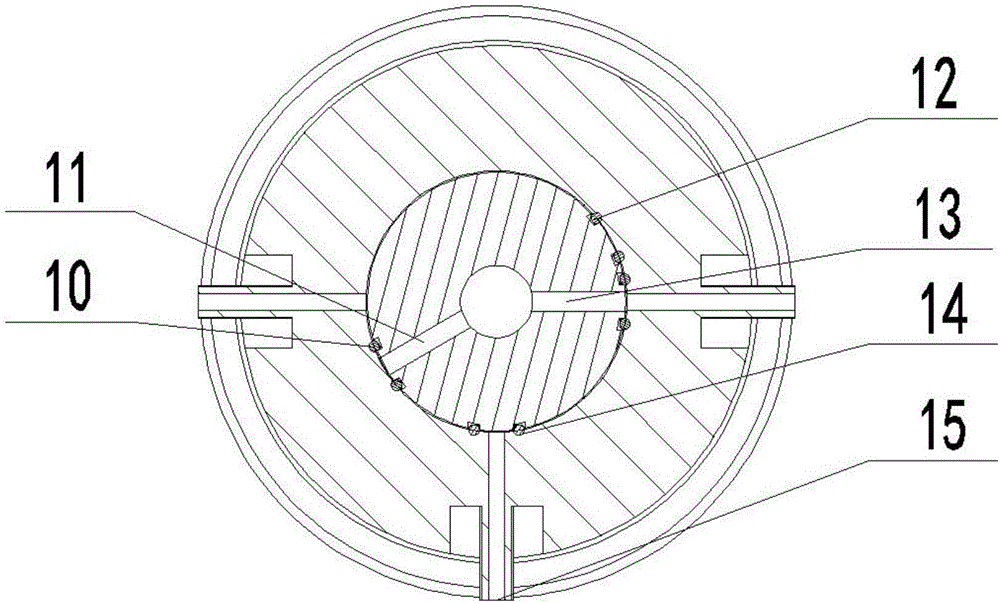

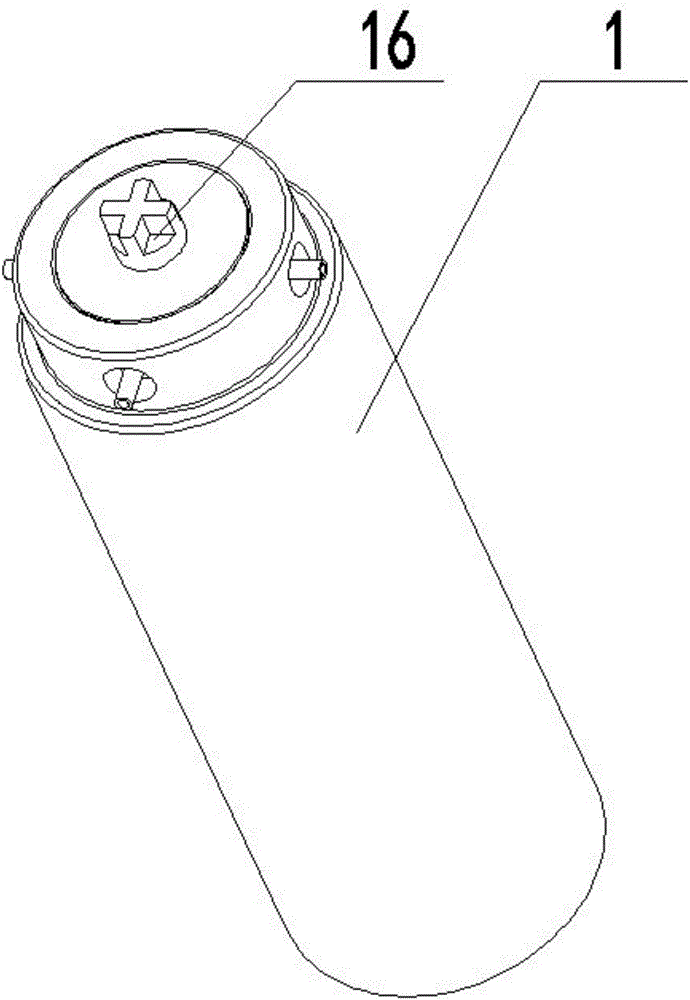

[0014] A filter element backwashing device, comprising a filter element 2, a clean water storage chamber 9 is provided inside the filter element 2, a filter bottle 1 is placed outside the filter element 2, and a raw water storage is provided between the filter bottle 1 and the filter element 2 Cavity 8, a filter bottle cap 3 is installed on the top of the filter bottle, and a raw water inlet hole 5, a clean water outlet hole 6 and a flushing water outlet hole 15 are opened on the filter bottle cap 3, and a switch The rotary switching mechanism of the filter element water purification and backwashing state, the rotary switching mechanism includes a switching turntable 7 fixedly connected to the top of the filter element, the outer wall of the switching turntable 7 and the inner wall of the filter bottle are provided with a communication raw water storage chamber 8 and The raw water inlet hole 5 and the raw water circulation channel 4 of the flushing water outlet hole 15 are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com