Sample bottle capping machine used for sample collect regulation

A technology of capping machine and sample bottle, which is applied in the direction of flanged bottle caps, etc., which can solve the problems of difficult separation, heavy labor, and capping failure, so as to improve the accuracy of docking, prevent safety accidents, and long pressing and setting strokes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

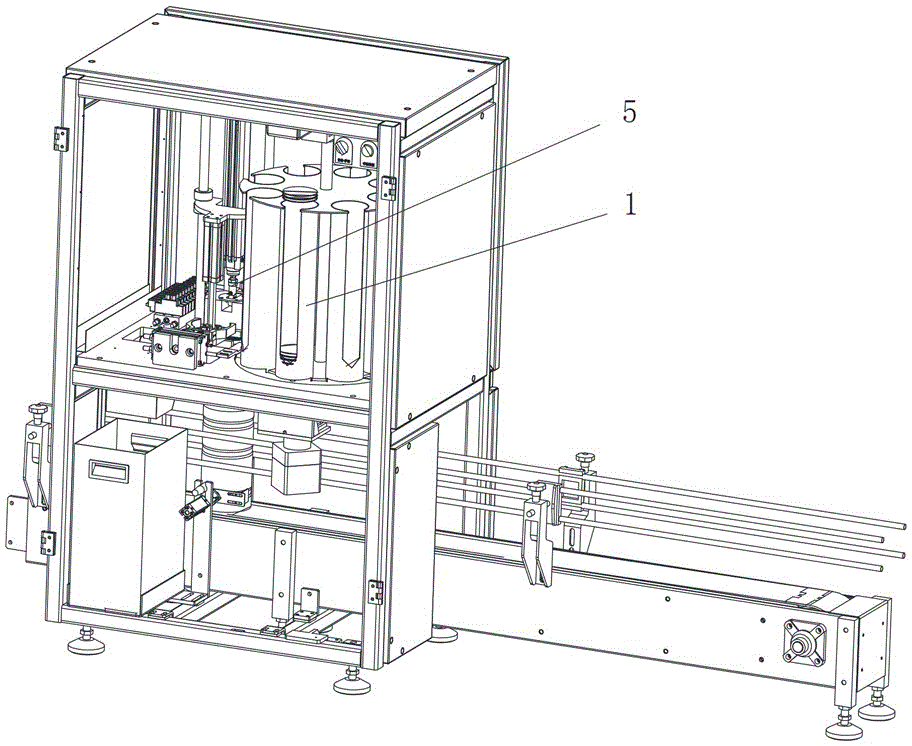

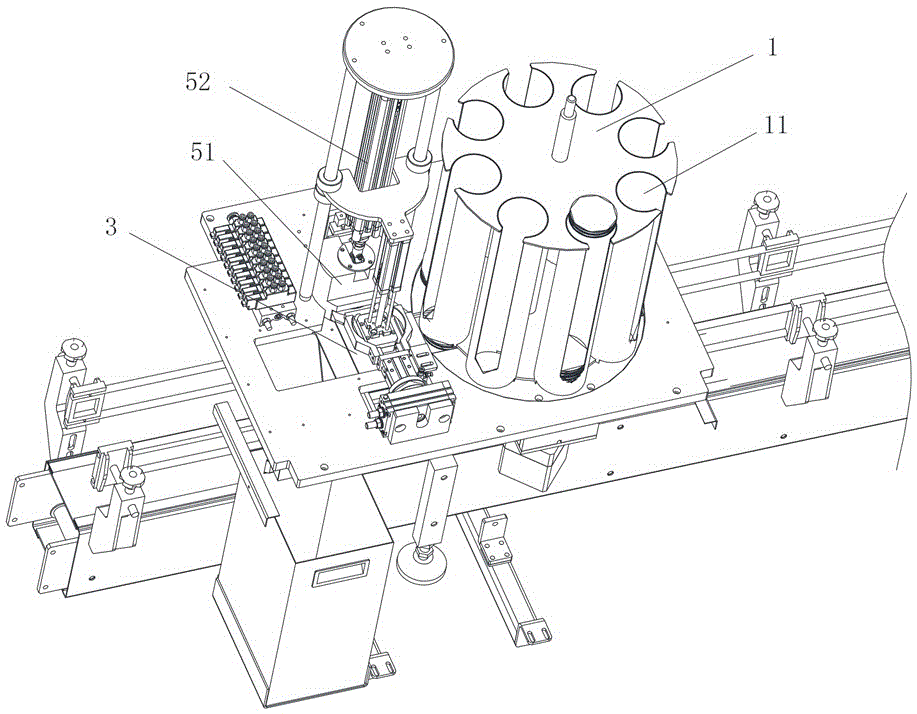

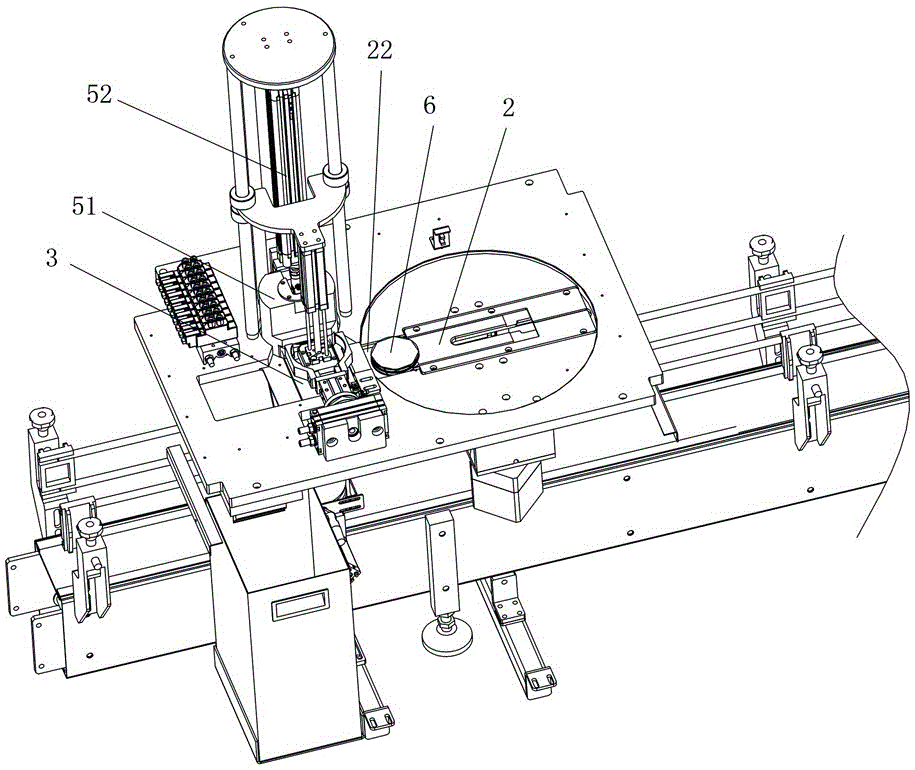

[0039] like Figure 1 to Figure 8 As shown, the present invention provides a sample bottle capping machine for sample collection and preparation, including a storage mechanism 1, a translation jacking mechanism 3 and a capping mechanism 5, and the storage mechanism 1 is used to store a plurality of bottles with the caps facing downwards. Cap 6, the translation jacking mechanism 3 has a translation stroke for translating and transporting the bottle cap 6 output by the storage mechanism 1 to the bottom of the capping mechanism 5. The capping mechanism 5 includes a matching capping punch 51 and a capping lift The driver 52, the capping punch 51 is provided with a suction cup 511 for absorbing and fixing the bottle cap 6, and the cap lifting driver 52 is arranged above the capping punch 51 to drive the capping punch 51 to move downward To co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com