High-speed shaftless driven metal tank printer

A shaftless transmission, metal can technology, used in printing presses, rotary printing presses, general parts of printing machinery, etc., can solve the problem that printing accuracy and speed are limited by mechanical structure, operator's technical experience is highly dependent, installation, maintenance Difficulty and other problems, to avoid disturbance and error infection, low energy consumption, easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

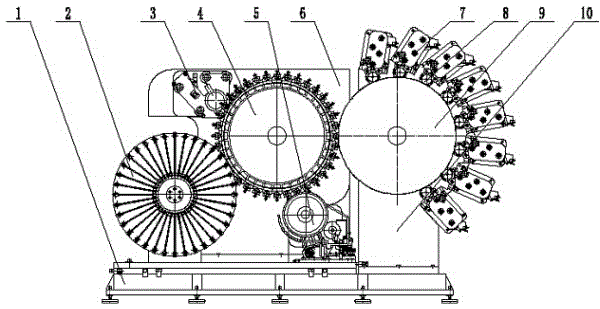

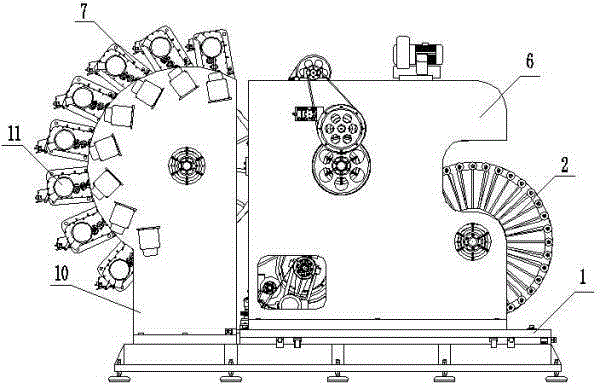

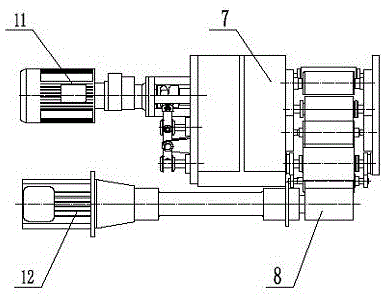

[0022] like figure 1 and figure 2 As shown, a high-speed shaftless transmission metal can printing machine includes a machine base 1, a rear frame 6, a can feeding mechanism 3, a mandrel turntable 4, a transmission plate 2, a varnish machine 5, a front frame 10, glue The plate wheel 9, the printing plate cylinder 8 and the inking mechanism 7 are characterized in that: the front frame 10 and the rear frame 6 are installed on the base 1, and the core is installed in the middle of the rear frame 6. Shaft turntable 4, the outer circle of the mandrel turntable 4 is evenly equipped with several sets of movable mandrel assemblies, and the mandrel roller 16 at the rear of the mandrel assembly can move along the cam groove on the frame with the rotation of the mandrel turntable 4. Rolling, the tank feeding mechanism 3 is located at the upper left corner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com