Rotary assembly robot gripper

A robot gripper and frame technology, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of unsatisfactory multi-function, poor versatility, and small adaptability, etc., achieve compact structure, reduce labor intensity, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

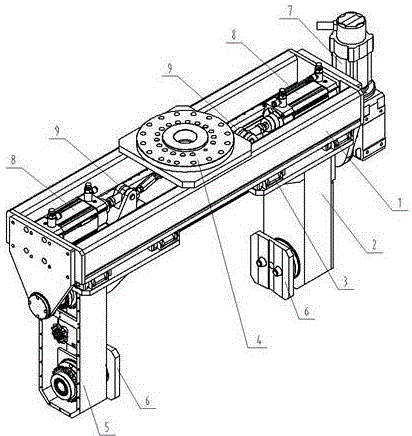

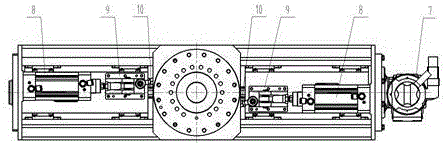

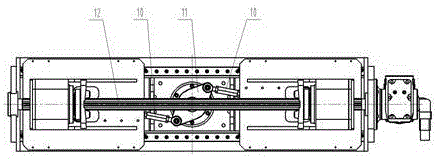

[0015] The present invention will be further described below in conjunction with the accompanying drawings. As shown in Figures 1 to 3, a rotary combined robot gripper includes: frame 1, left gripper arm 2, linear guide rail 3, connecting plate 4, right gripper arm 5, gripper 6, servo motor 7, cylinder 8 , hinge seat 9, connecting rod 10, synchronous rotation mechanism 11, and ball spline 12; among them, the connecting plate 4 is installed on the frame 1 to connect with the robot arm, and a pair of parallel linear guide rails 3 are fixed on the frame 1. The arm 2 and the right grabbing arm 5 are equipped with a chain transmission mechanism, and any structure in the prior art can be used, and will not be repeated here. The left grabbing arm 2 and the right grabbing arm 5 are symmetrically installed on the left and right sides of the linear guide rail 3. Can slide along the linear guide 3.

[0016] A hinge seat 9 is fixed on the left grabbing arm 2 and the right grabbing arm 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com