Robot for taking out springs

A robot and spring machine technology, applied in the field of robotics, can solve problems such as difficulty in falling into the box, difficulty in manual sorting, long spring length, etc., and achieve the effect of good clamping effect, high grasping quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

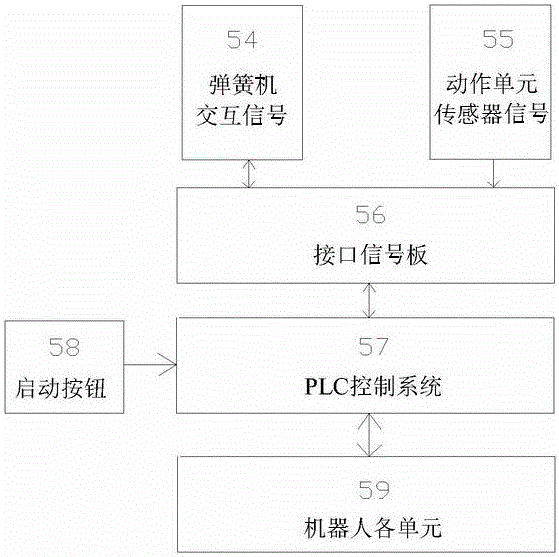

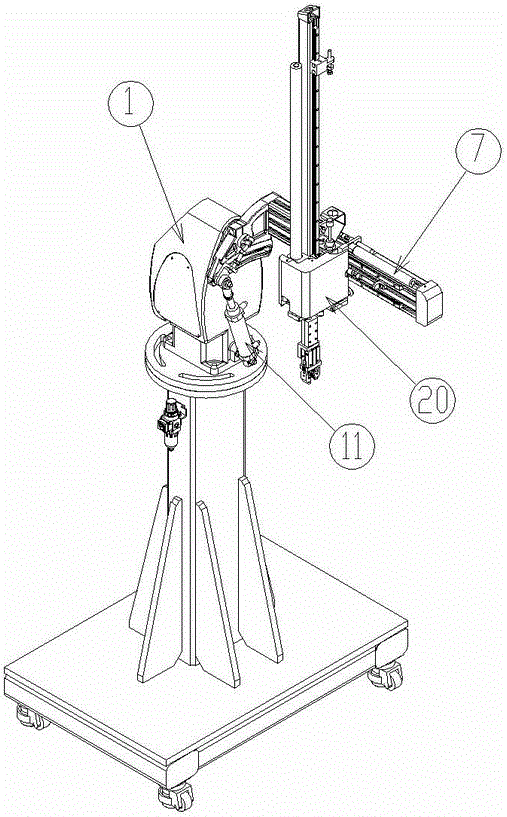

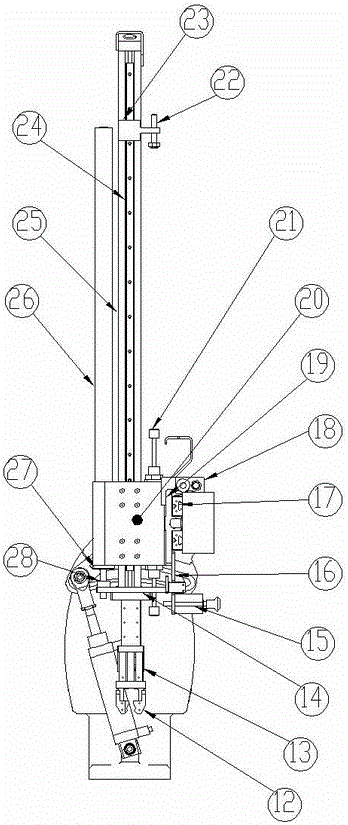

[0022] Such as figure 1 , figure 2 , image 3 As shown, the rotating flange 2 is connected to the body 1 through the rotating base shaft 3, the cylinder barrel of the cylinder 2 11 is connected to the body 1, the piston rod of the cylinder 2 11 is connected to one end of the rotating flange 2, and the other end of the rotating flange 2 One end is connected with the transverse shaft 4. When the piston rod of the cylinder 2 11 is ejected, the rotating flange 2 rotates around the rotating base shaft 3, so that the entire transverse shaft 4 and the vertical shaft 25 also turn over a certain angle. 2 is designed with a section of angle adjustment groove, loosen the lock nut, slide the screw connecting the rotating flange 2 and the piston rod to a suitable position, and then lock the lock nut, the horizontal axis 4 and the vertical axis 25 can be adjusted Flip angle (≤90°). The cylinder barrel of cylinder one 7 is fixed by transverse axis cylinder fixing plate 18, and the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com