Plane joint robot with length of arms capable of being adjusted

A planar joint and adjustable technology, applied in the field of robotics, can solve the problems of fixed working space and inability to adapt to various working space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

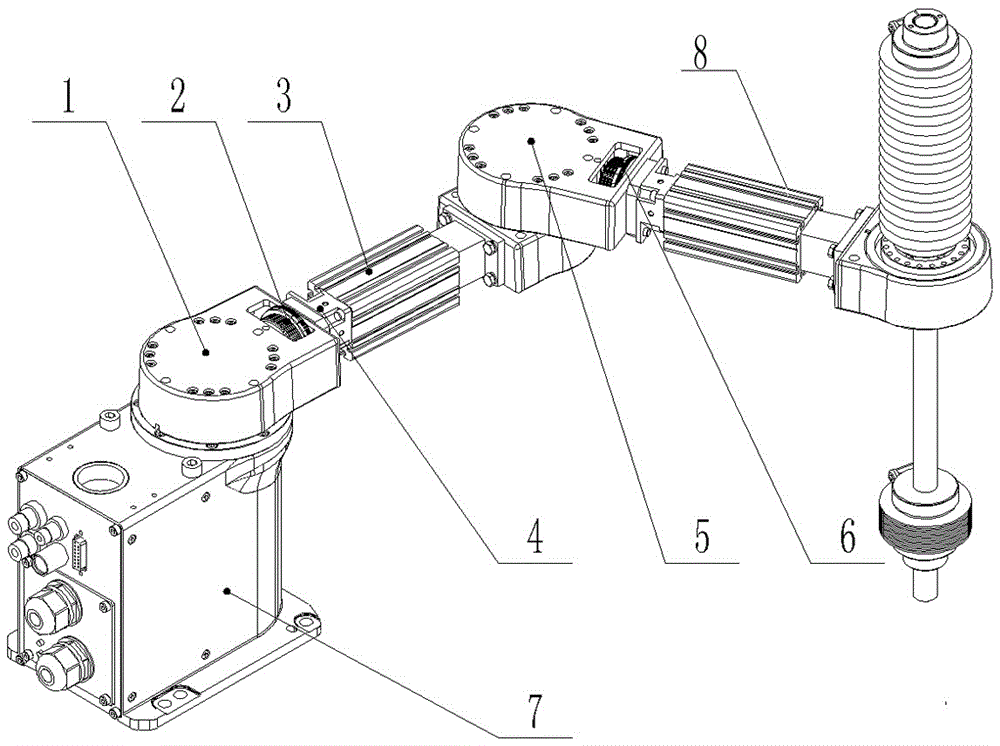

[0011] The structure and principle of the planar joint robot with adjustable length arm of the present invention will be described in detail below with reference to the drawings and embodiments.

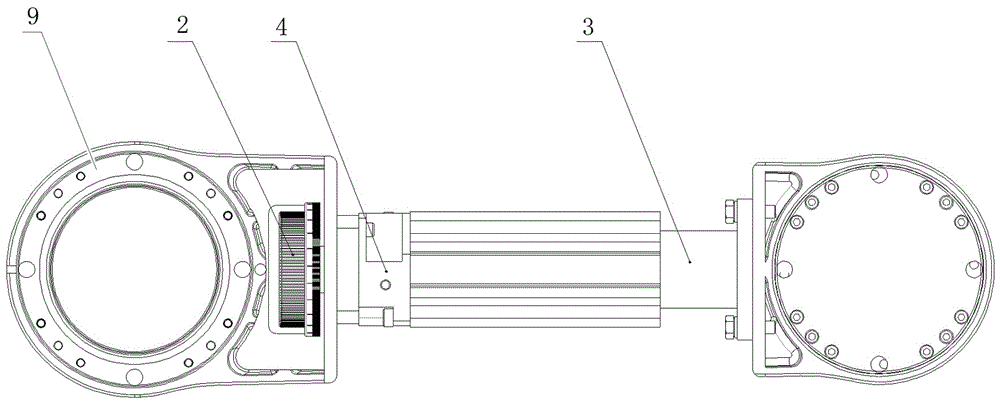

[0012] Such as figure 1 As shown, the planar joint robot with adjustable length arm of the present invention includes a power part 7, a first horizontal rotating arm and a second horizontal rotating arm, wherein the first horizontal rotating arm and the second horizontal rotating arm have the same structure. Such as figure 1 and 2 As shown, the first horizontal rotating arm includes a first horizontal shaft 1, a first length adjustment wheel 2, a first telescopic link 3 and an electronic brake 4, and the first length adjustment wheel 2 and the first telescopic link 3 pass through the link The internal ball screw is connected, and the electronic brake 4 is fixed together with the joint of the first horizontal shaft 1 and the first telescopic connecting rod 3 through bolts.

[0013]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com