Control device and method for planar three-degree-of-freedom parallel robot driven by rodless cylinder

A rodless cylinder and control device technology, which is applied to program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of complex circuit design, oil leakage environment, oil viscosity changes, etc., to reduce control difficulty and respond quickly. , the effect of reducing the installation position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

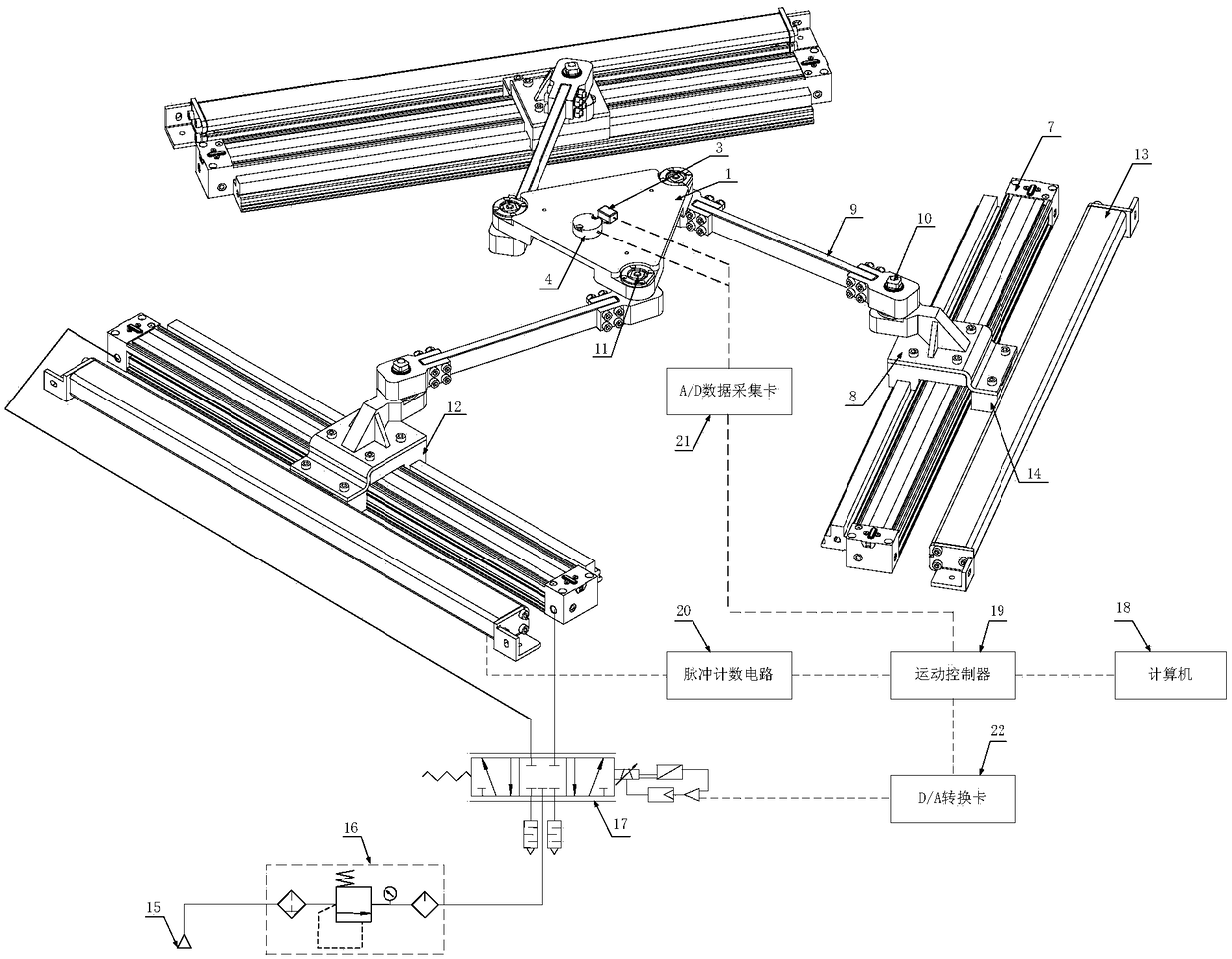

[0035] like figure 1 and figure 2 As shown, this embodiment provides a planar three-degree-of-freedom parallel robot control device, which includes a planar three-degree-of-freedom parallel robot body and a control assembly.

[0036] The body of the planar three-degree-of-freedom parallel robot is a 3PRR (3 moving-rotating-rotating branches) type motion platform, including a moving platform 1, a static platform 2 and three parallel drive control branches, figure 1 The structure of static platform 2 is hidden in , the purpose is to describe the control components of the device more clearly, figure 2 Lieutenant General Jing Platform 2 expressed in detail, figure 1 The dotted line connection in the figure indicates the connection between the electrical signal and the control component, and the solid line connection indicates the connection of the pneumatic control circuit;

[0037] The moving platform 1 is a triangular plate, and the result of the output device operation is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com