Double-station automatic feeding device for silicon steel sheet welding

An automatic material feeding and welding station technology, applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low welding operation efficiency, achieve short moving distance, improve welding accuracy, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

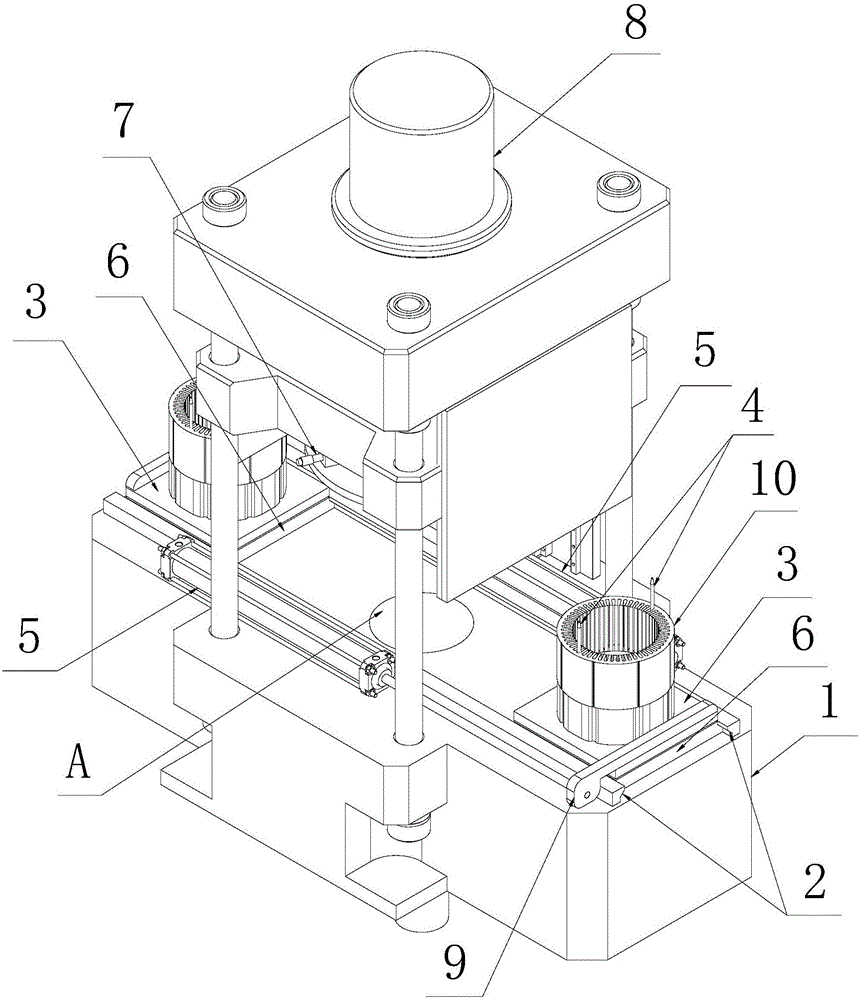

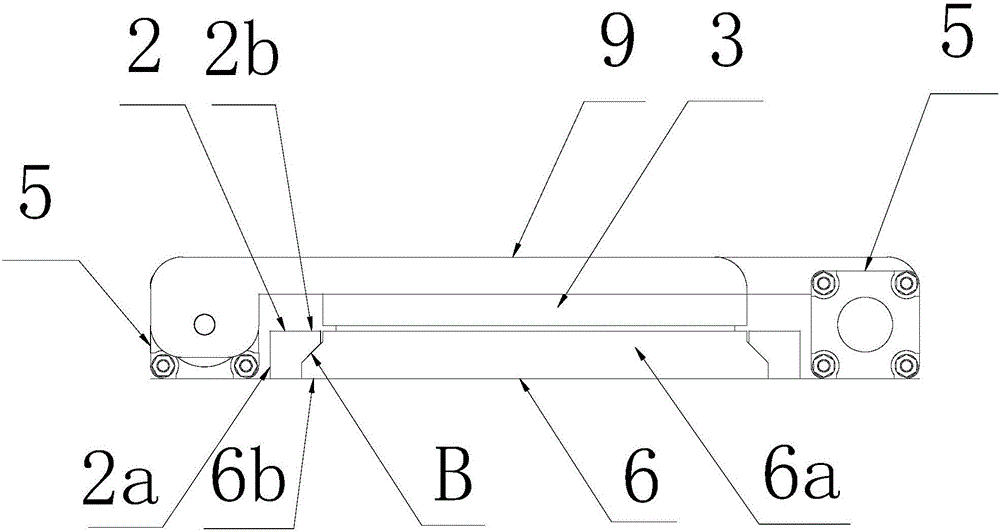

[0020] Example: Combined figure 1 and figure 2 As shown, the specific implementation of the dual-station automatic feeding device for silicon steel sheet welding of the present invention is described as follows:

[0021] This device is the same as conventional technology, has the workbench 1 that is provided with welding station A and is located at workbench 1 top and is opposite to welding mechanism 7 and pressurization mechanism 8 with welding station A, as figure 1 As shown, the welding station A is located in the middle of the workbench 1 . The main improvement of the present invention is that two guide rails 2 arranged in parallel to pass through the welding station A are set on the workbench 1, and two guide rails 2 are slid on the two guide rails 2 for placing silicon steel sheet positioning jigs. 4 sliding stage 3, the two sliding stages 3 are respectively connected to a translation drive mechanism, and are independently reciprocated on the parallel guide rails 2 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com