Hot heading extrusion feeding manipulator

A manipulator and feeding technology, applied in the field of manipulators, can solve the problems of insufficiency of small and medium-sized enterprises, large volume, complex structure, etc., and achieve the effects of low cost, good stability and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

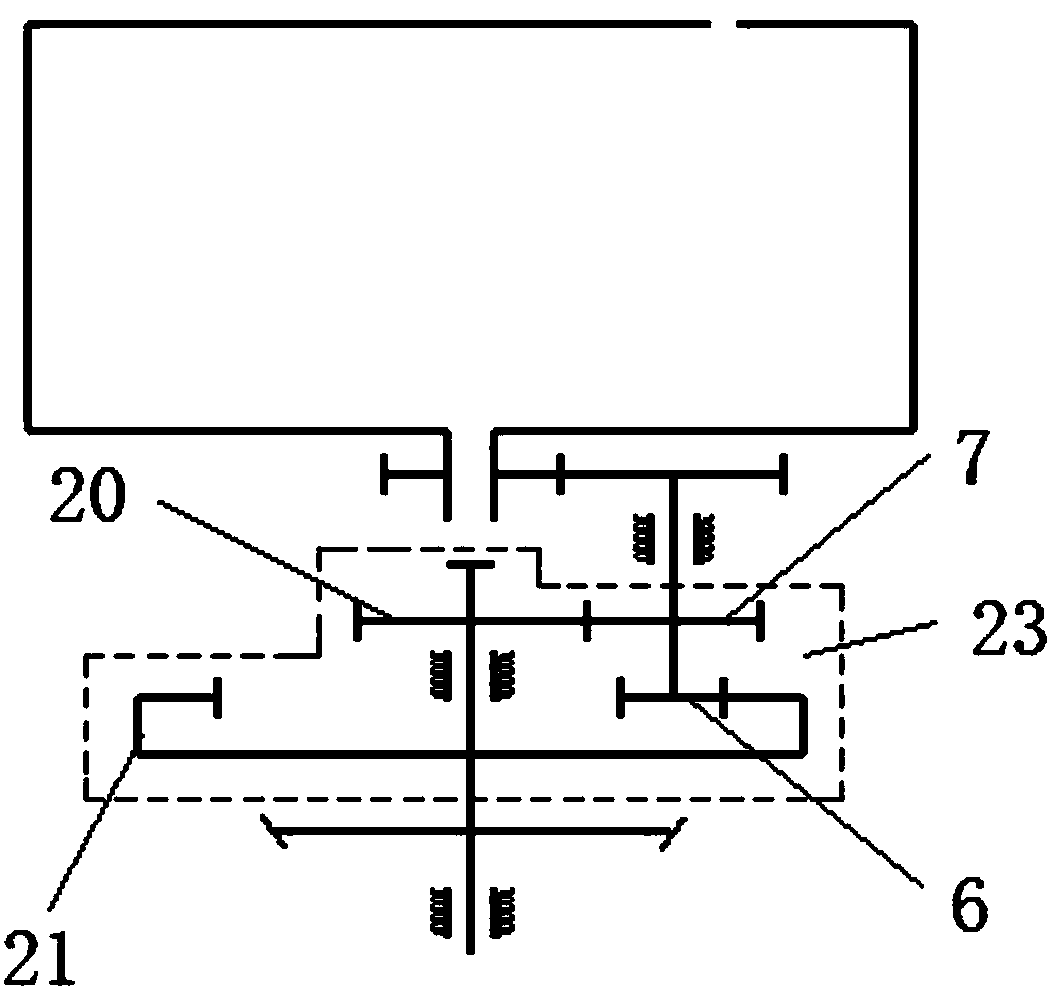

[0023] Such as figure 1 Shown, a kind of hot upsetting extrusion feeding manipulator comprises driving device, arm swing mechanism and arm turning mechanism; Described driving device is motor 1, and it provides power for the motion of arm swing mechanism and arm turning mechanism; Described arm turning mechanism Including incomplete gear mechanism 23, cylindrical gear mechanism and mechanical handpiece body 17, mechanical handpiece body 17 and incomplete gear mechanism 23 transmit motion through coupling 19, incomplete gear mechanism 23 meshes with cylindrical gear mechanism, and drives the mechanical handpiece The body 17 makes intermittent rotary motions; the arm swing mechanism is installed on the mechanical mobile phone body 17 and swings up an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com