Cleaning equipment and photovoltaic module cleaning system

A technology for cleaning equipment and photovoltaic panels, which is applied in photovoltaic modules, photovoltaic power generation, cleaning and flexible items, etc., can solve the problems of long cycle, large photovoltaic power station area, and high cost, and achieves a wide range of applications, simple and compact equipment structure, and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

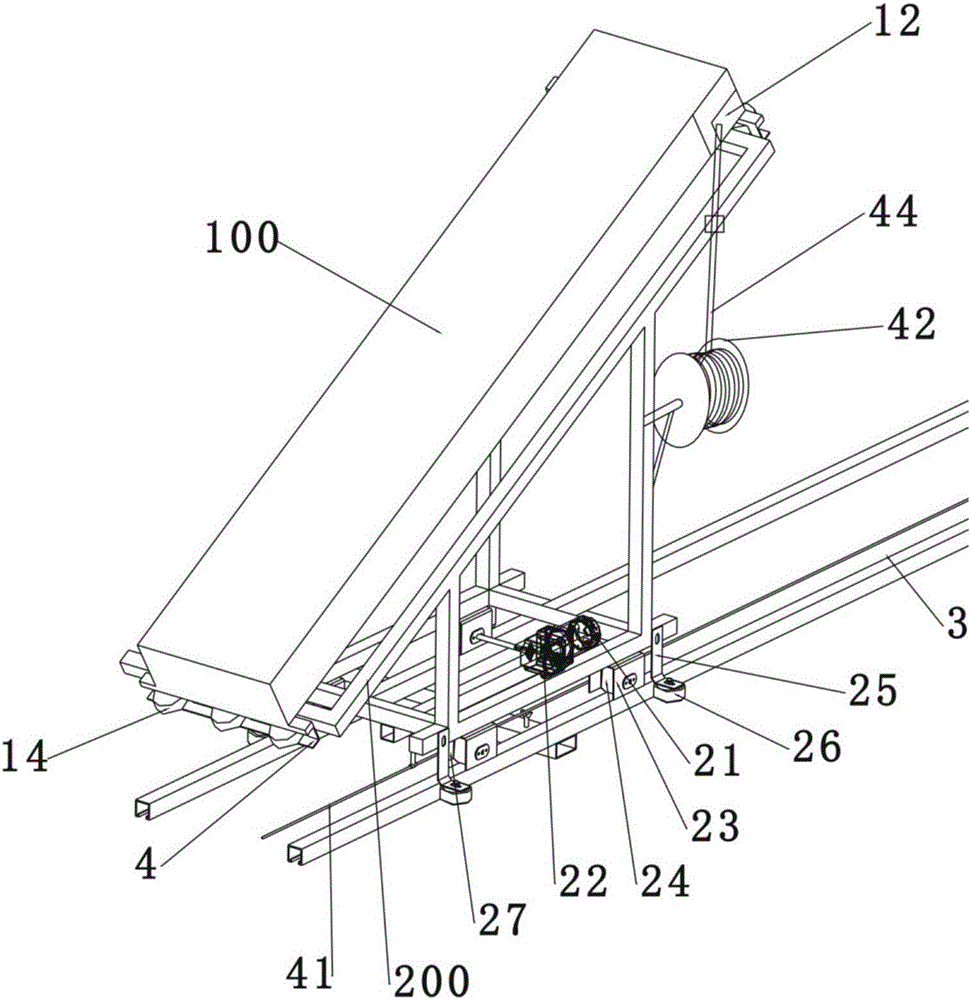

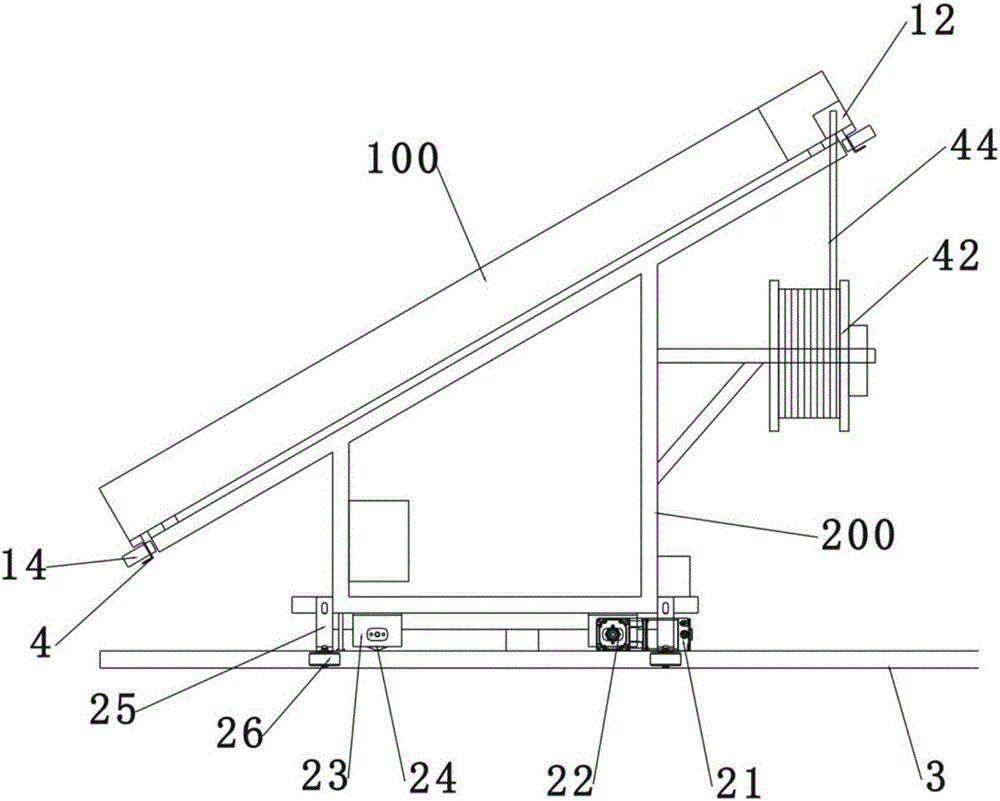

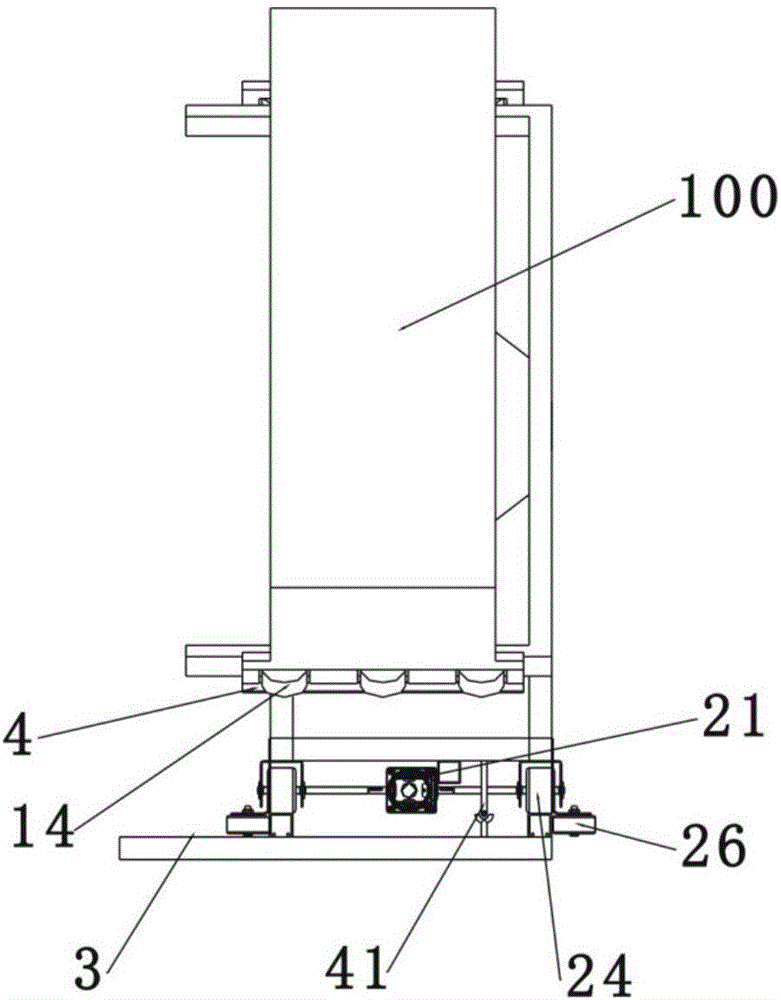

[0028] The technical scheme adopted by the present invention involved in the present invention is a cleaning device, including a cleaning machine 1, a mobile dock 2, a guide rail 3 and a control system, the mobile dock 2 is used to carry the cleaning machine 1, and the control system Under the control of the control system, the cleaning machine 1 can move with the mobile dock 2 under the control of the control system.

[0029] The mobile wharf 2 includes a loading frame 200, a first driving device, and a first traveling mechanism. The cleaning machine 1 is firmly placed on the loading frame 200, and the loading frame 200 is at a certain inclination angle, which is consistent with the array Photovoltaic panels 500 are consistent. The cleaning machine 1 can be fastened on the loading frame 200 through the clamping block 4 . The first driving device includes a transmission-connected first motor 21 and a reduction box 22. During operation, the first motor 21 drives the reduction ...

Embodiment 2

[0033] A photovoltaic module cleaning system using the cleaning equipment in Embodiment 1, the array photovoltaic panel 500 is an m*n matrix, m and n are both positive integers, Figure 4Shown in is the matrix of m=1, n=3. During work, the guide rail 3 is placed on one side of the array photovoltaic panel 500, the mobile dock 2 is placed above the guide rail 3, and the cleaning machine 1 is loaded on the carrier 200 of the mobile dock 2 Above all, the inclination angle of the carrier frame 200 should be basically consistent with the inclination angle of the array photovoltaic panel 500, so as to make the cleaning cleaner without hindering the operation of the cleaning machine. A certain tolerance is allowed for the inclination angle. When there is an angle tolerance, it is necessary to properly adjust the height of the carrier frame 200 and then adjust the height of the cleaning machine 1 to ensure that the operation does not get stuck. The cleaning machine 1 is on the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com