A pressure telescopic cleaning device

A cleaning device and telescopic technology, which is applied in the field of pressure telescopic cleaning devices, can solve the problems that the cleaning cannot be completed at one time, cannot meet the requirements of simple structure and convenient use of the cleaning device, and the price of the cylinder is high, so as to meet market needs and reduce production costs. Low, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

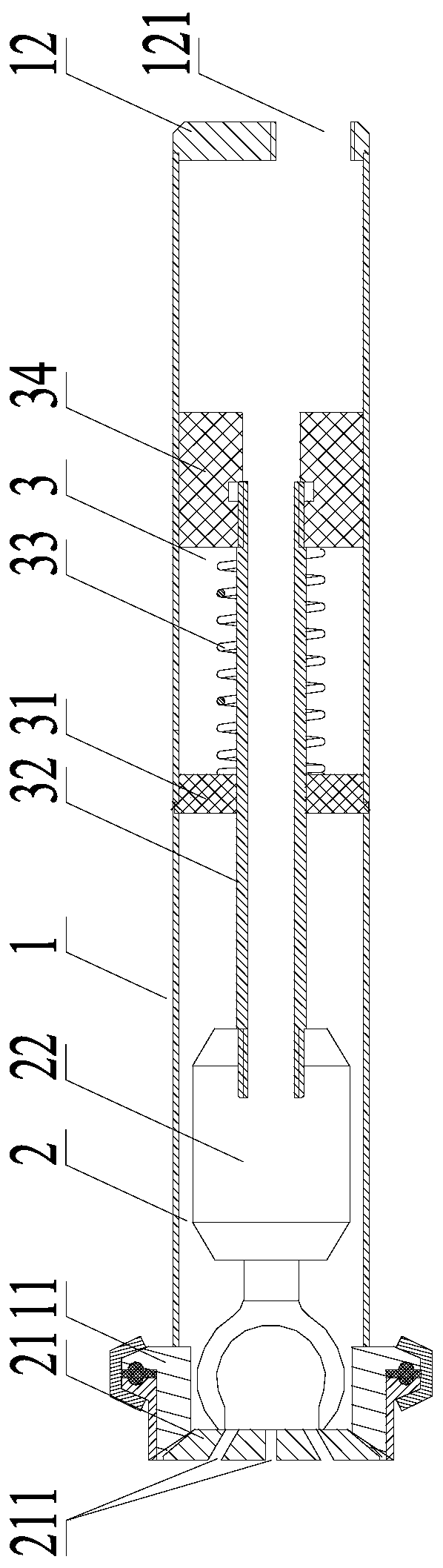

[0028] Such as figure 1 As shown, a pressure telescopic cleaning device provided in Embodiment 1 of the present invention includes a lumen assembly 1 , a cleaning assembly 2 and a telescopic assembly 3 , and the cleaning assembly 2 and the telescopic assembly 3 are connected and sheathed in the lumen assembly 1 .

[0029] The lumen assembly 1 is a cylindrical structure, with an inner clamp joint 11 at one end and an end blocking plate 12 at the other end. The end blocking plate 12 is provided with an opening 121 along the axial direction of the lumen assembly 1 .

[0030] The cleaning assembly 2 includes a cleaning ball blocking plate 21 and a cleaning ball 22. The cleaning ball blocking plate 21 is provided with a cleaning medium outlet 211, and the end is closely matched with the outer end surface of the inner clamp joint 11. The cleaning ball 22 is a cavity structure. The ends are respectively fixedly connected with the cleaning ball blocking plate 21 and the telescopic ass...

Embodiment 2

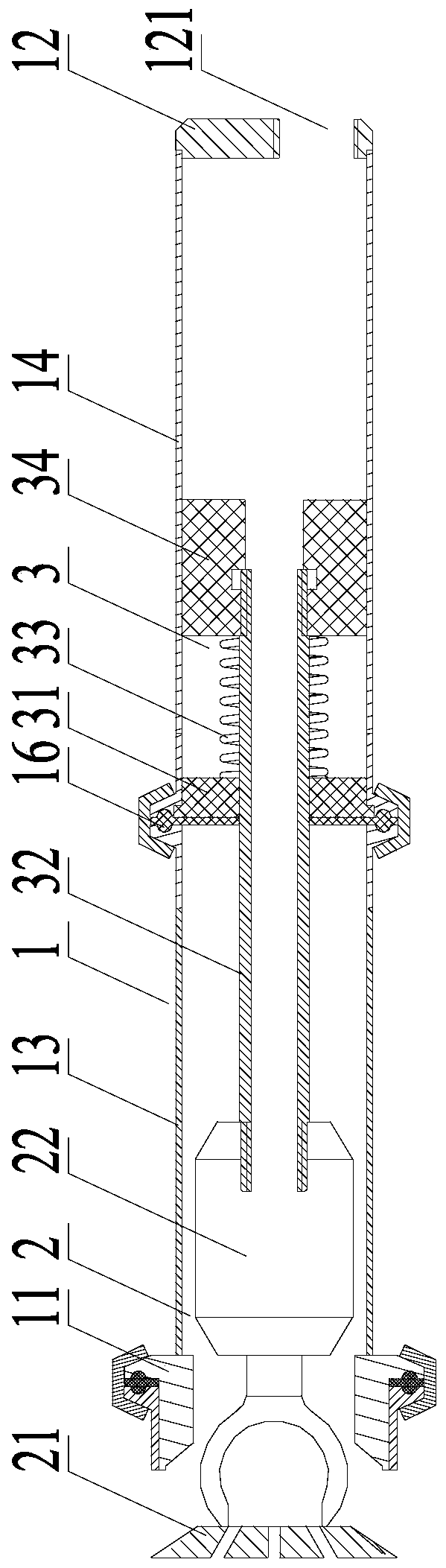

[0035] The pressure telescopic cleaning device provided in Embodiment 2 of the present invention is similar in structure to the pressure telescopic cleaning device provided in Embodiment 1 of the present invention, except that the lumen assembly 1 consists of a first lumen 13 and a The second lumen 14 is spliced by the clamp 15, and the first fixed sleeve 31 is fixedly clamped between the first lumen 13 and the second lumen 14. In addition, the first lumen 13 and the first fixed sleeve There is also a first sealing ring 16 between 31, and the first sealing ring 16 is a silicone sealing ring.

[0036] The working principle and working process of the pressure telescopic cleaning device provided in this embodiment are similar to those in Embodiment 1, and will not be described in detail here. The structural diagram in its working state is as follows figure 2 shown.

Embodiment 3

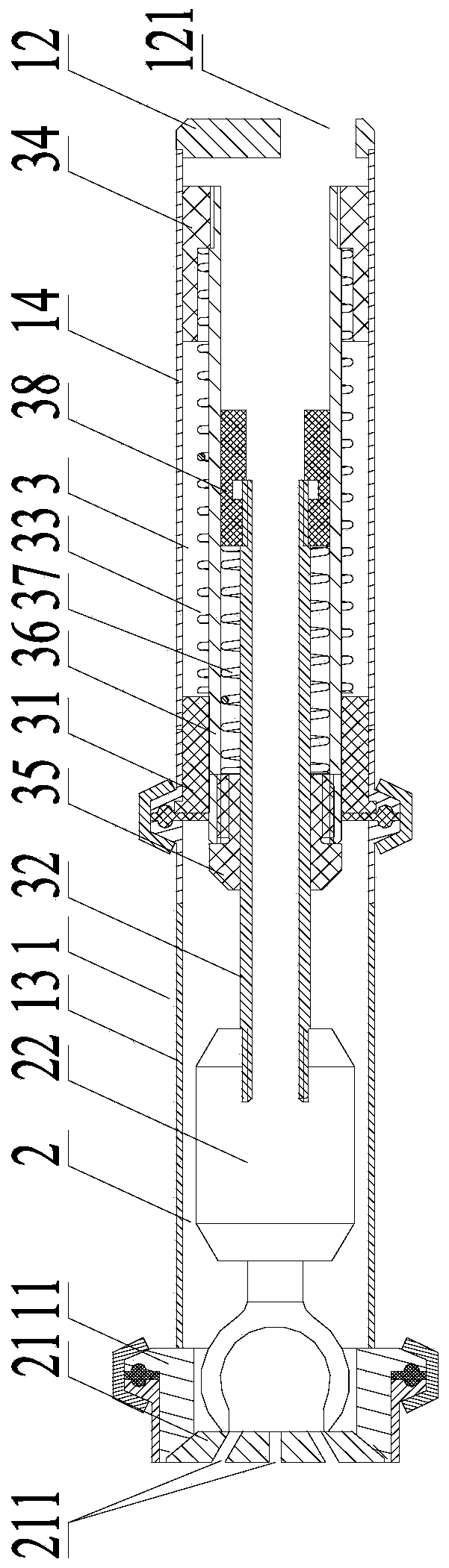

[0038] Such as image 3As shown, the pressure telescopic cleaning device provided in Embodiment 3 of the present invention is similar in structure to the pressure telescopic cleaning device provided in Embodiment 2 of the present invention, the difference is that the telescopic assembly 3 also includes a second fixed Sleeve 35, second connecting pipe 36, second spring 37 and second movable sleeve 38, second fixed sleeve 35, second connecting pipe 36, second spring 37 and second movable sleeve 38 are socketed together Forming an integral telescopic clamp between the first connecting pipe 32 and the first spring 33, the second connecting pipe 36 is telescopically sleeved in the first spring 33, and one end is fixedly arranged in the inner hole of the first movable sleeve 34, The other end passes through the first fixed sleeve 31 and is movably sleeved in the lumen assembly 1, and the second fixed sleeve 35 is fixedly arranged in the inner hole of the second connecting pipe 36 ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com