Spraying machine for skid-resistant cold glue special for goods stacking and spraying application method of spraying machine

A technology of spraying machine and cold glue, which is applied in the direction of coating, spraying device, and device for coating liquid on the surface, etc. It can solve the problems of increased storage costs and high power consumption of hot melt adhesives, and achieves saving production time and energy saving Anti-slip cost, reduce the effect of working links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in combination with specific embodiments.

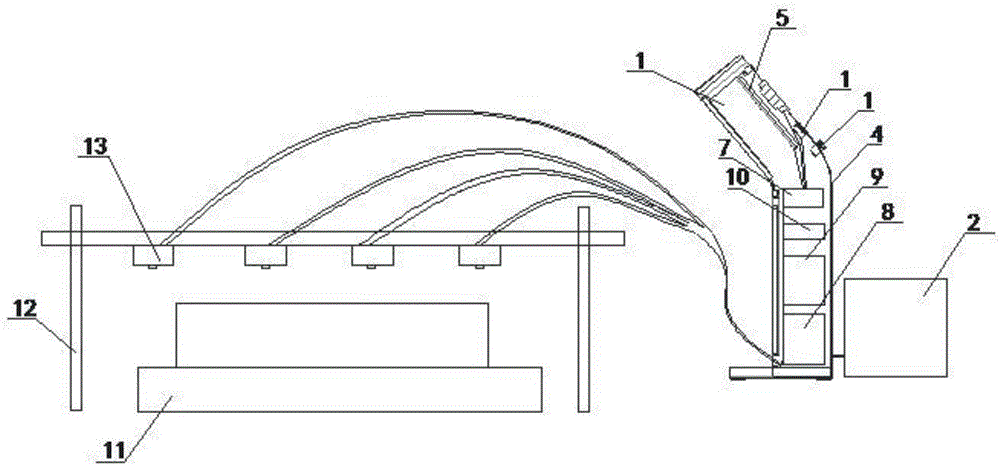

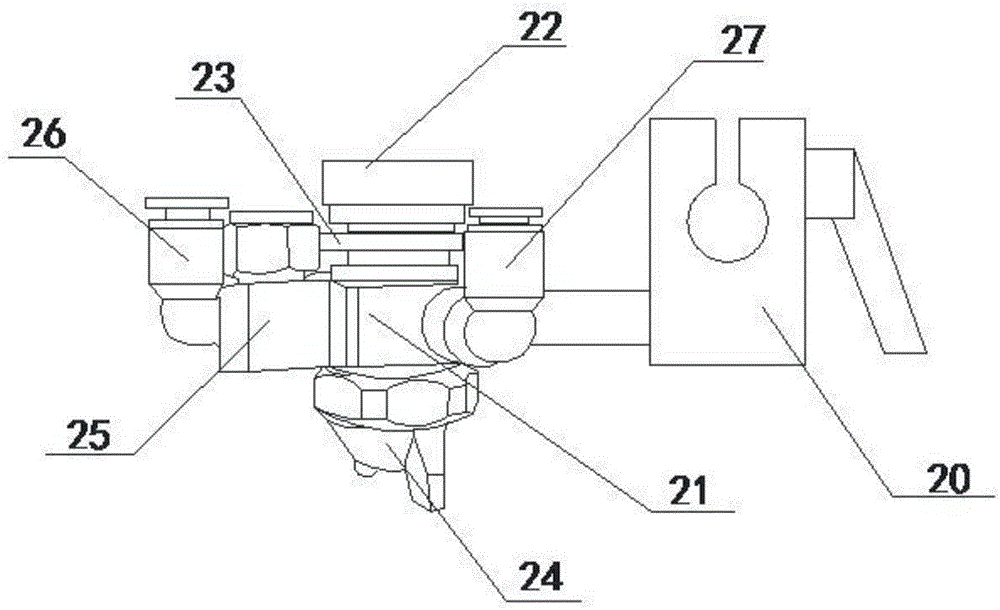

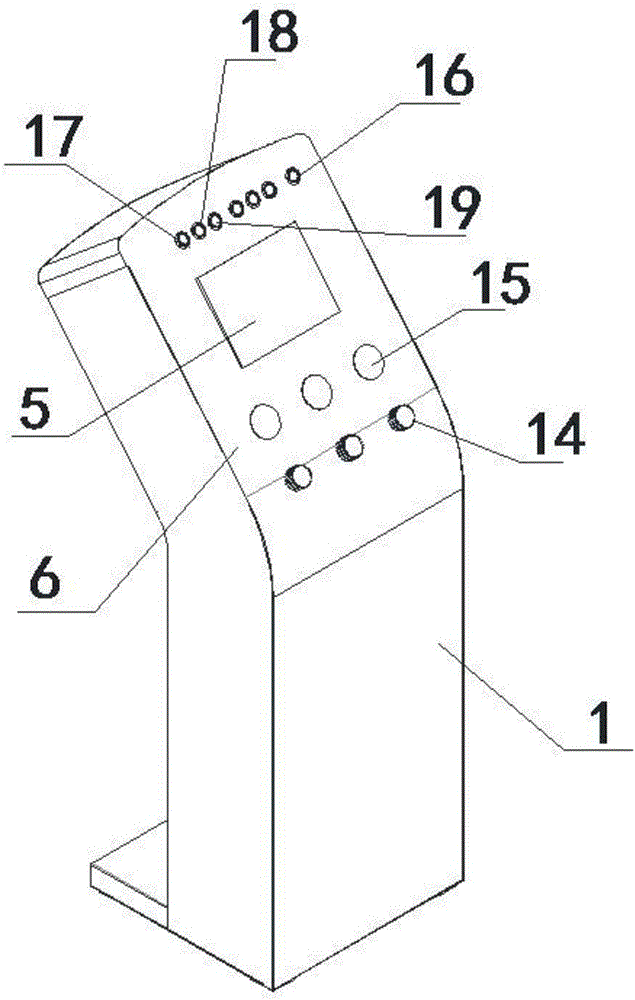

[0026] A special anti-slip cold glue spraying machine for cargo stacking, such as Figure 1-3 As shown, it includes a host 1, the host 1 is connected to the raw material barrel 2 through a pipeline, and the host 1 is connected to the cold glue spraying device assembly 3 through a pipeline; the host 1 includes a shell 4, and a display 5 is arranged on the top of the shell 4, A control panel 6 is installed on one side of the display 5, the display 5 is electrically connected to the control circuit board 7, the control panel 6 is electrically connected to the control circuit board 7, the control circuit board 7 is electrically connected to the input power supply, and the control The circuit board 7 is electrically connected to the glue supply pump 8, the control circuit board 7 is electrically connected to the water separator 9, and the control circuit board 7 is electricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com