Two-stage filtering self-cleaning filter adopting internal and external filter cylinders

A self-cleaning filter and two-stage filtration technology, which is applied in the direction of fixed filter elements, membrane filters, filtration separation, etc., can solve the problems of increasing the length, and achieve the goals of reducing height, high filtration accuracy, and saving flow loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

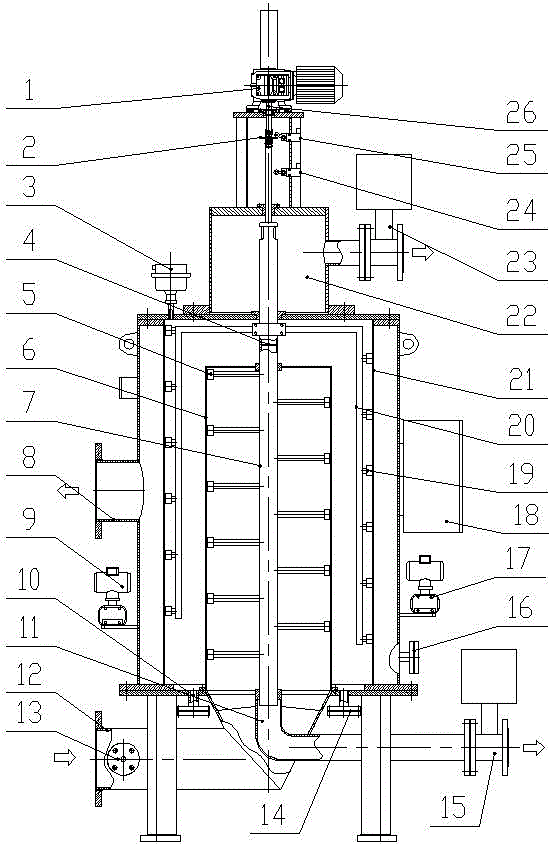

[0021] figure 1 As shown, the specific implementation is as follows:

[0022] A secondary filter self-cleaning filter for inner and outer filter cartridges, including a sealed housing for forming a filter chamber, a sewage suction pipe 7 and a driving device 1, the housing is provided with a water inlet 12 and a water outlet 8, and the sewage suction pipe 7 It extends into the casing and is driven by the driving device 1 to work the sewage suction pipe. It is characterized in that: the casing is provided with a first-stage filter cartridge 6 and a second-stage filter cartridge 21, and the first-stage filter cartridge 6 is covered in the inlet The water port is located on the opening in the shell to isolate the inner cavity of the shell into two spaces: the inner cavity of the first-stage filter cartridge and the outer cavity of the first-stage filter cartridge. The water inlet 12 communicates with the inner cavity of the first-stage filter cartridge, and water passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com