Cigarette with porous material

A porous material, cigarette technology, applied in the direction of tobacco, cigar manufacturing, application, etc., can solve the problems of difficult to approach the taste, low use temperature, light smoke, etc., to meet the smoking habits, reduce the amount of use, and satisfy the smoking quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

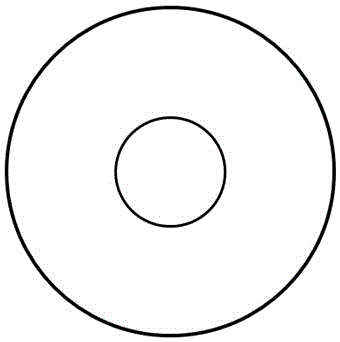

[0031] like figure 1 As shown, the cigarette of this embodiment includes a filter tip 1 and a cut tobacco rod 3, and a hollow tube 6 (made of cigarette paper) is arranged along the axial direction of the cut tobacco rod. A porous material 7 is arranged at the joint between the tube and the filter, and the shape is a circular piece with an area equal to the cross-sectional area of the cut tobacco rod. The control sample of the present invention is a conventional cigarette, the air permeability of the cigarette paper is 70 CU, and the number of cigarettes tested by the smoking machine is 20. In order to describe its effect more accurately, the CO emission in the smoke is calculated by grams of shredded tobacco, and the test results are shown in Table 1 ( Example 1).

Embodiment 2

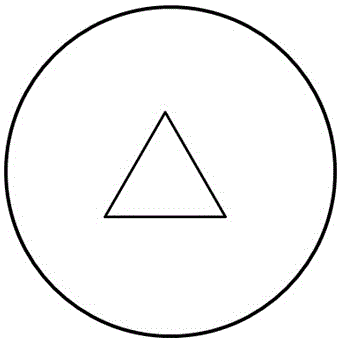

[0033] like Figure 5 As shown, the cigarette of this embodiment includes a filter tip 1 and a cut tobacco rod 3, and a hollow tube 6 (material is cigarette paper) is provided along the axial direction of the cut tobacco rod. The cross section of the hollow tube is circular and the diameter is 2 mm. . A porous material 7 is arranged at the junction of the hollow tube and the filter tip, the shape is a circular piece, the center is on the central axis of the cigarette, and the diameter of the circular piece is 3 mm. The control sample of the present invention is a conventional cigarette, the air permeability of the cigarette paper is 70 CU, and the number of cigarettes tested by the smoking machine is 20. In order to describe its effect more accurately, the CO emission in the smoke is calculated by gram weight of shredded tobacco, and the test results are shown in Table 1. (Example 2).

Embodiment 3

[0035] like Image 6 As shown, the cigarette of this embodiment includes a filter tip 1 and a cut tobacco rod 3, and a hollow tube 6 (material is cigarette paper) is arranged along the axial direction of the cut tobacco rod. The cross section of the hollow tube is circular and the diameter is 2.5 mm. . A cylindrical cellulose porous material with a length of 2 mm is embedded at the junction of the hollow tube and the filter. The control sample of the present invention is a conventional cigarette, the air permeability of the cigarette paper is 70 CU, and the number of cigarettes tested by the smoking machine is 20. In order to describe its effect more accurately, the CO emission in the smoke is calculated by gram weight of shredded tobacco, and the test results are shown in Table 1. (Example 3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com