Noise-free tobacco leaf unbundling and cutting machine

A cutting machine, noiseless technology, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of injury to personnel, gnawing knives, material layer jumping chains, etc., to achieve reduced labor intensity, convenient follow-up maintenance, high safety and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

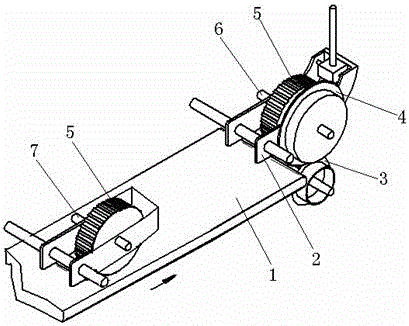

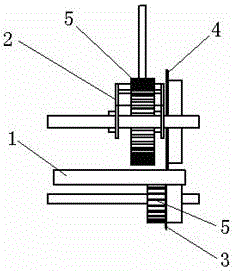

[0022] Such as Figure 1-4 , the tobacco leaf cutting machine that the present invention provides, comprises frame 2, is arranged on the conveyer belt 1 below frame 2, is arranged on the upper and lower hob 4,3 of conveyer belt 1 front end portion, is provided with elastic force on the frame Support the rolling wheel 5, the elastic supporting rolling wheel includes an inner supporting ring 51, an elastic supporting member arranged on the inner supporting ring 51, and a flexible outer ring 52 arranged on the periphery of the elastic supporting member; the elastic supporting rolling wheel 5 They are respectively arranged on the cutter shafts 6 of the upper and lower hobs 4 and 3, and the two ends of the cutter shaft 6 are fixed on the frame 2 through bearings and bearing seats, so that each elastic support rolling wheel 5 can follow the upper and lower cutter shafts 6 R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com