Component mounting machine

A technology for installing machines and components, applied in the direction of electrical components, electrical components, manipulators, etc., can solve the problems of reduced productivity, increased number of types, increased frequency of replacing chuck devices, etc., and achieve the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, an example which actualizes the embodiment for implementing this invention is demonstrated.

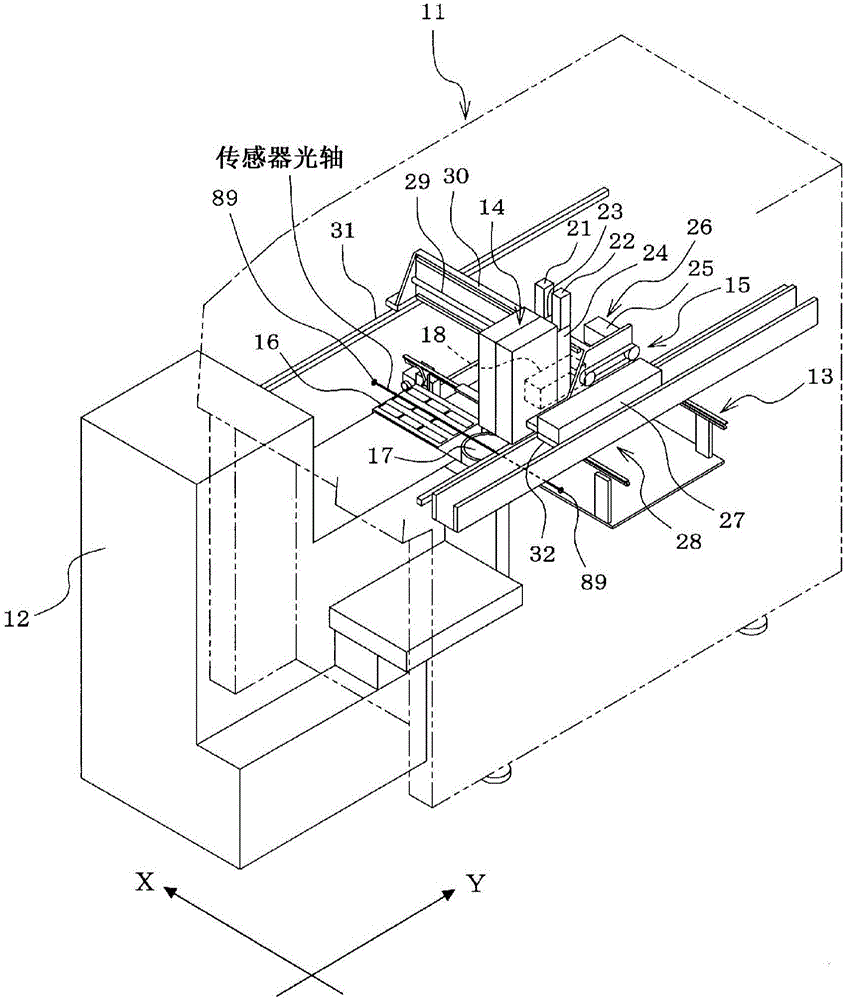

[0038] First, based on figure 1 The structure of the component mounting machine 11 will be described.

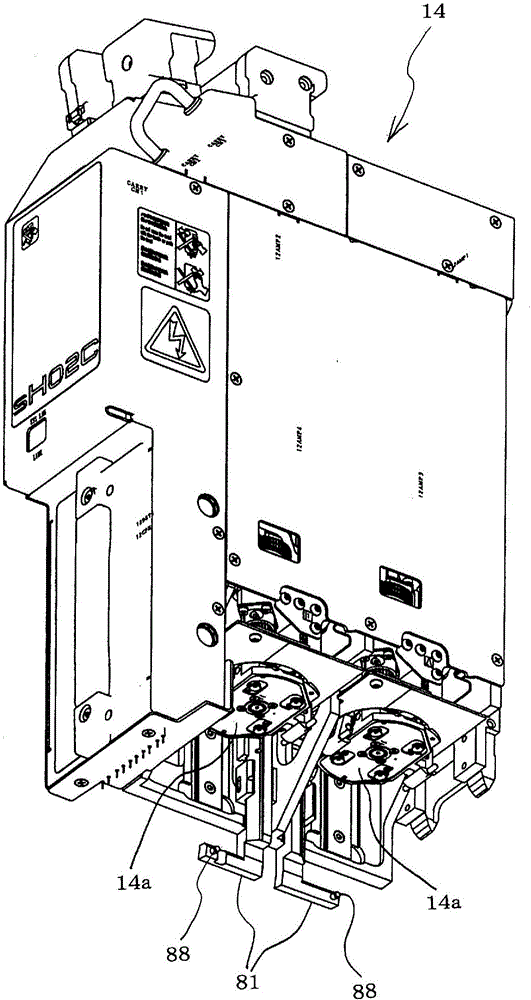

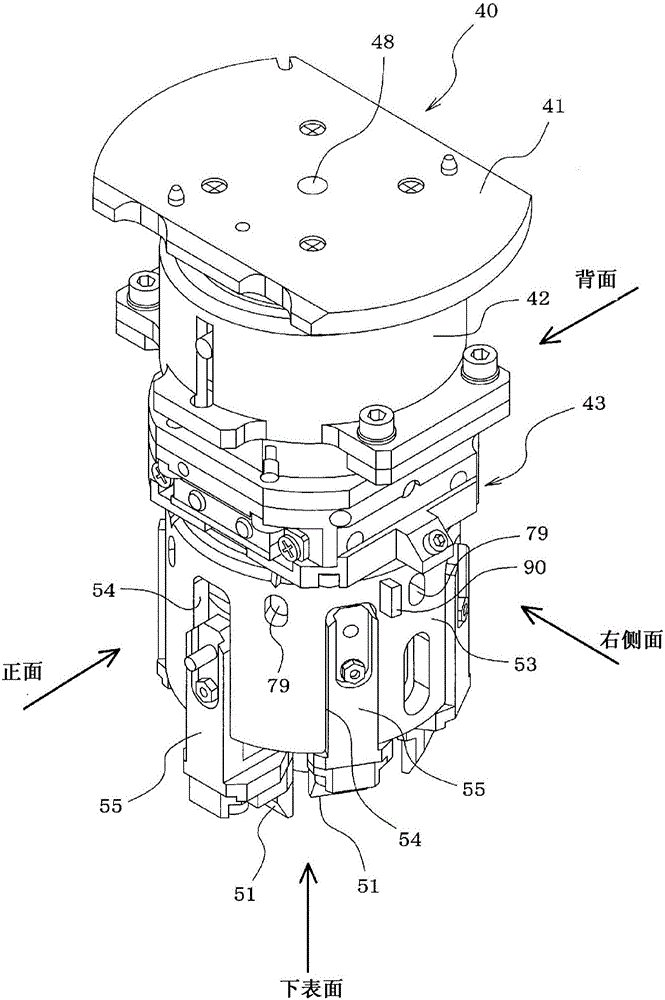

[0039] A component supply device 12 for supplying components is detachably provided on the component mounting machine 11 . The component supply device 12 provided in the component mounting machine 11 can be any one of a tray feeder, a tape feeder, a bulk feeder, a bar feeder, etc. Of course, it is also possible to mix and load a variety of feeder. The component mounting machine 11 is provided with a conveyor 13 for conveying circuit boards (not shown), a mounting head 14 for mounting components supplied from the component supply device 12 on the circuit board, and the mounting head 14 is arranged along the XY axis directions (left and right). The XY-axis moving mechanism 15 that moves in the front-rear direction), the tool station 16 on which the tool for repl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com