Detection equipment for reed

A testing equipment and reed technology, applied in measuring devices, instruments, using ultrasonic/sonic/infrasonic waves, etc., can solve the problems of high equipment cost, uneven width, deformation, etc., and achieve low equipment cost, high accuracy, and application wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

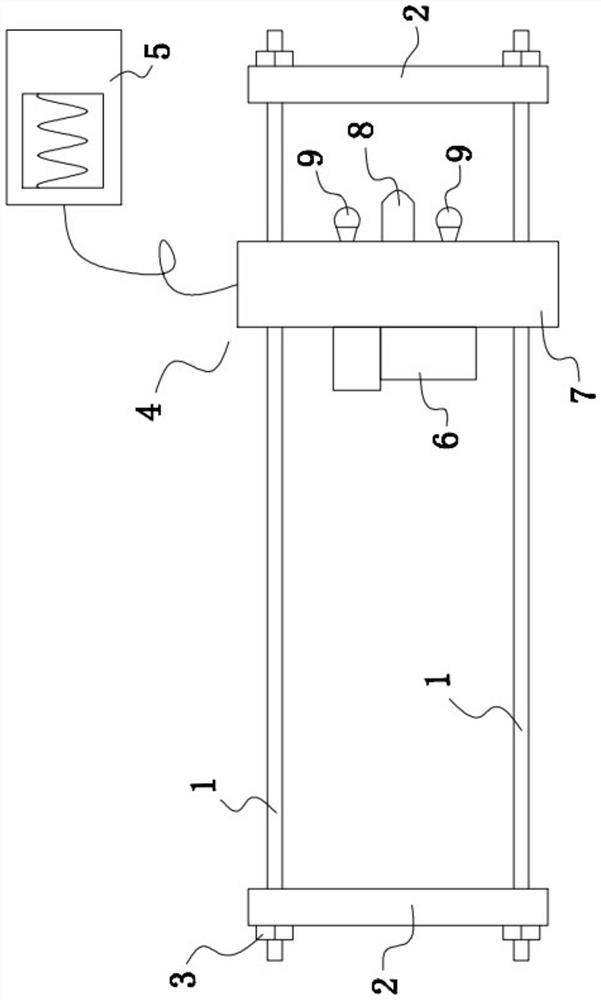

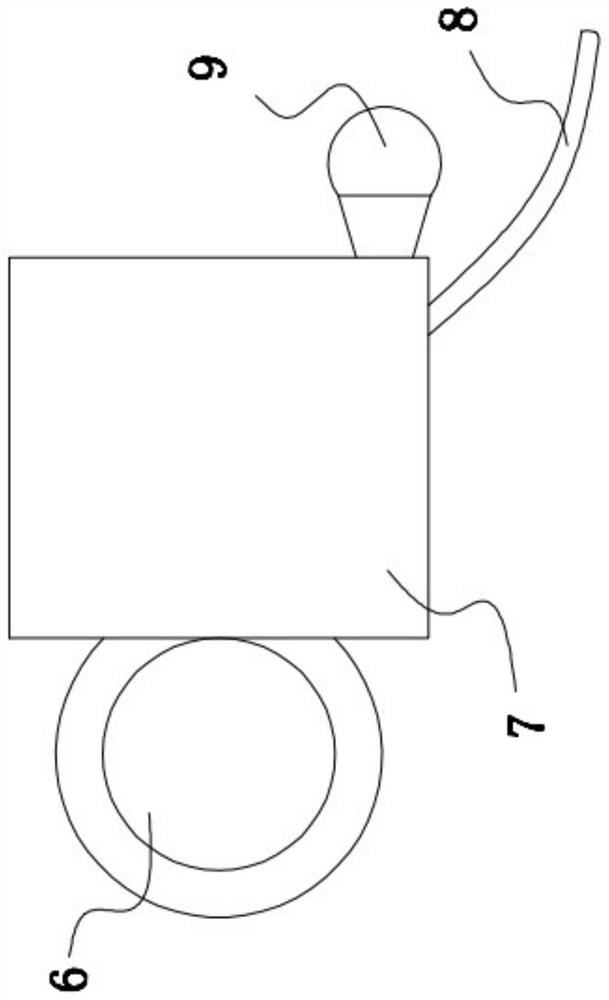

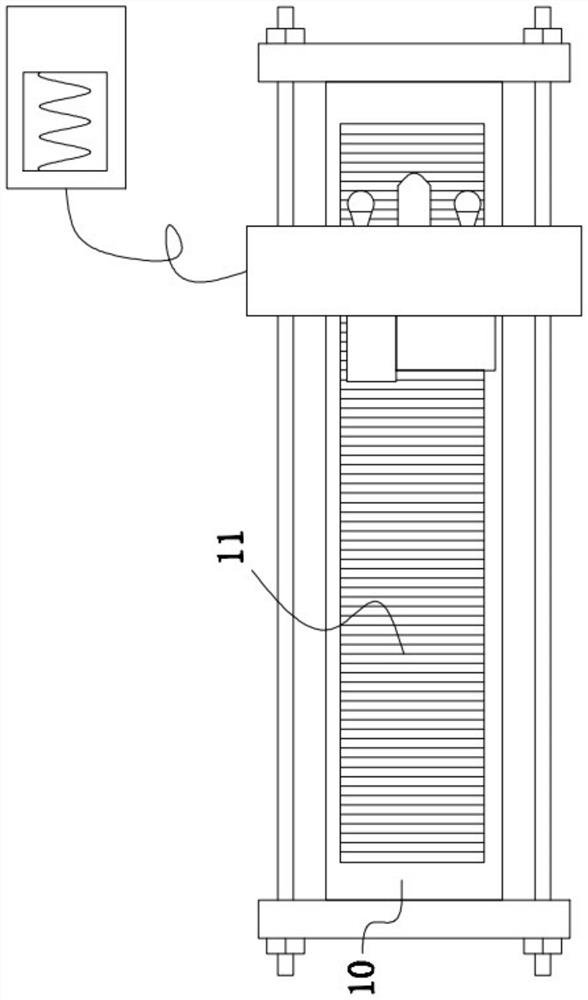

[0025] In order to achieve the purpose of the present invention, a detection device for reeds includes: a clamping mechanism, including two compression blocks 2, the clamping mechanism includes a screw 1 that runs through the two compression blocks 2, and the screw 1 The top assembly is equipped with a nut 3 in contact with the compression block 2, and the two compression blocks 2 clamp the steel reed 10 together, and the steel reed 10 is arranged in a single row with several rows of teeth 11; the toggle mechanism 4 includes a set In the translation block 7 between the two compression blocks 2, the translation block 7 is penetrated by the screw mandrel 1, and the translation block 7 is equipped with a rotating motor 6 that drives the translation block 7 to translate along the length direction of the lead screw 1, and the translation block 7 is equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com