Device and method for converting heat energy

A technology of thermal energy and thermal energy conversion, applied in the field of thermal energy devices, can solve problems such as unsatisfactory results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

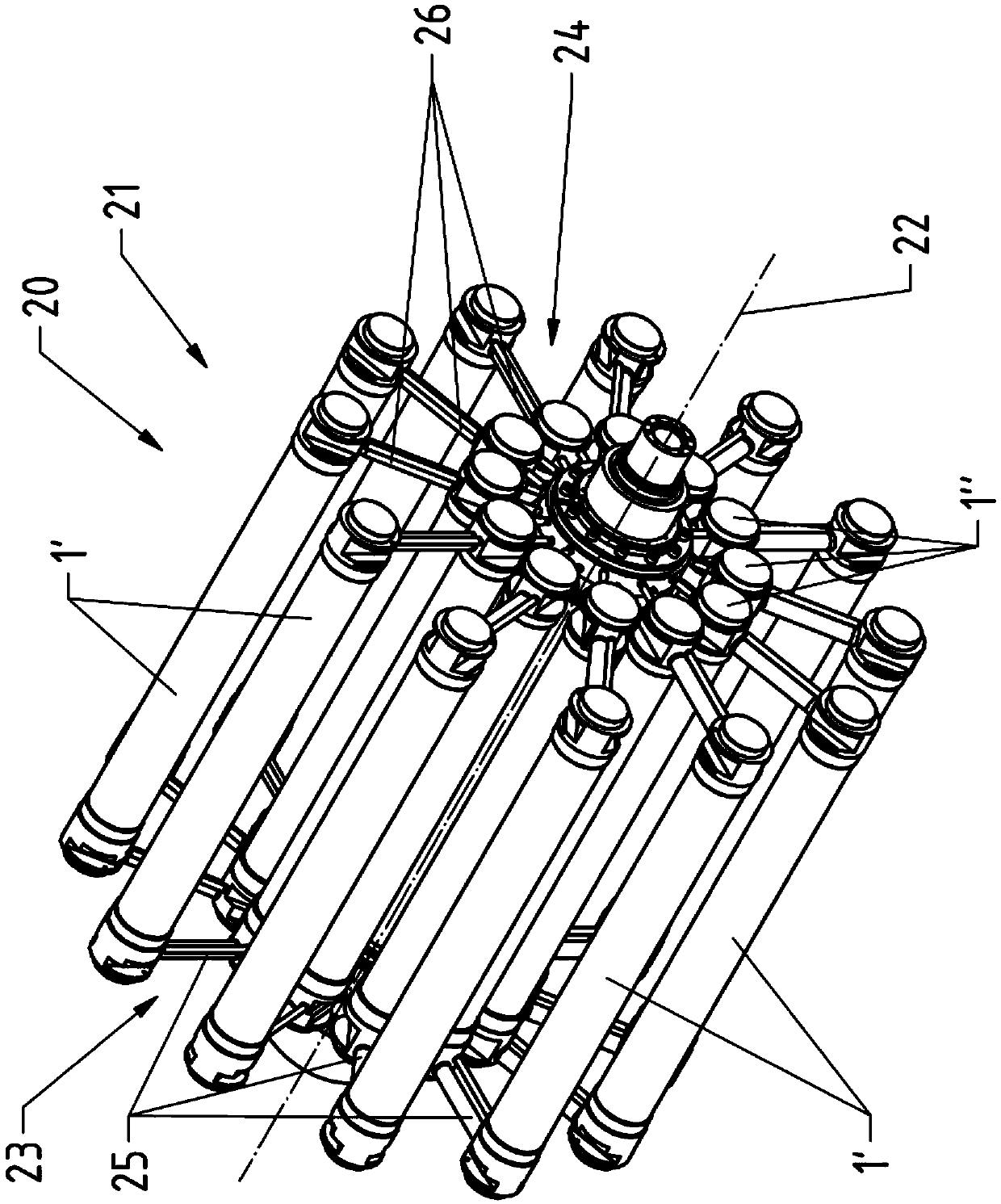

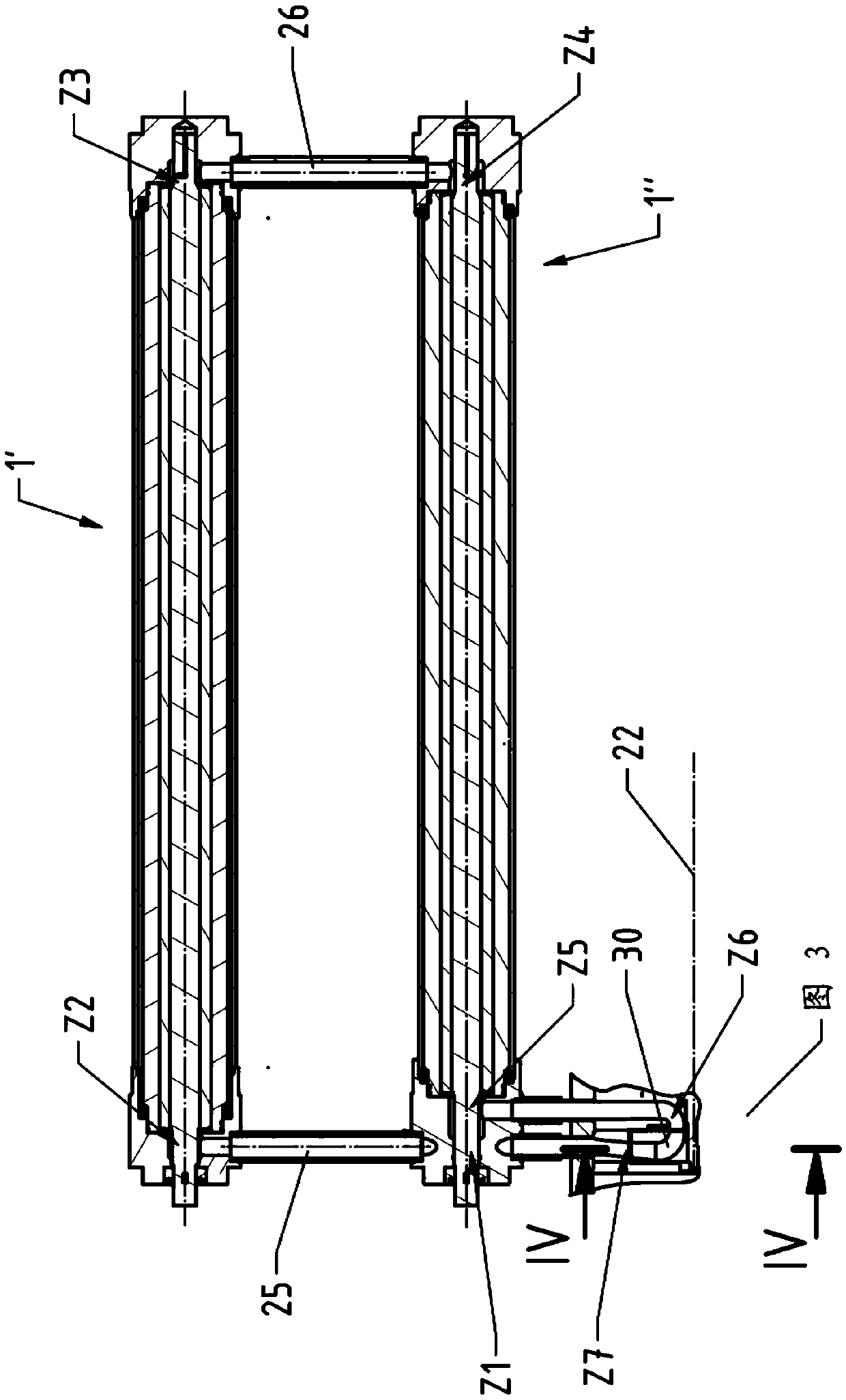

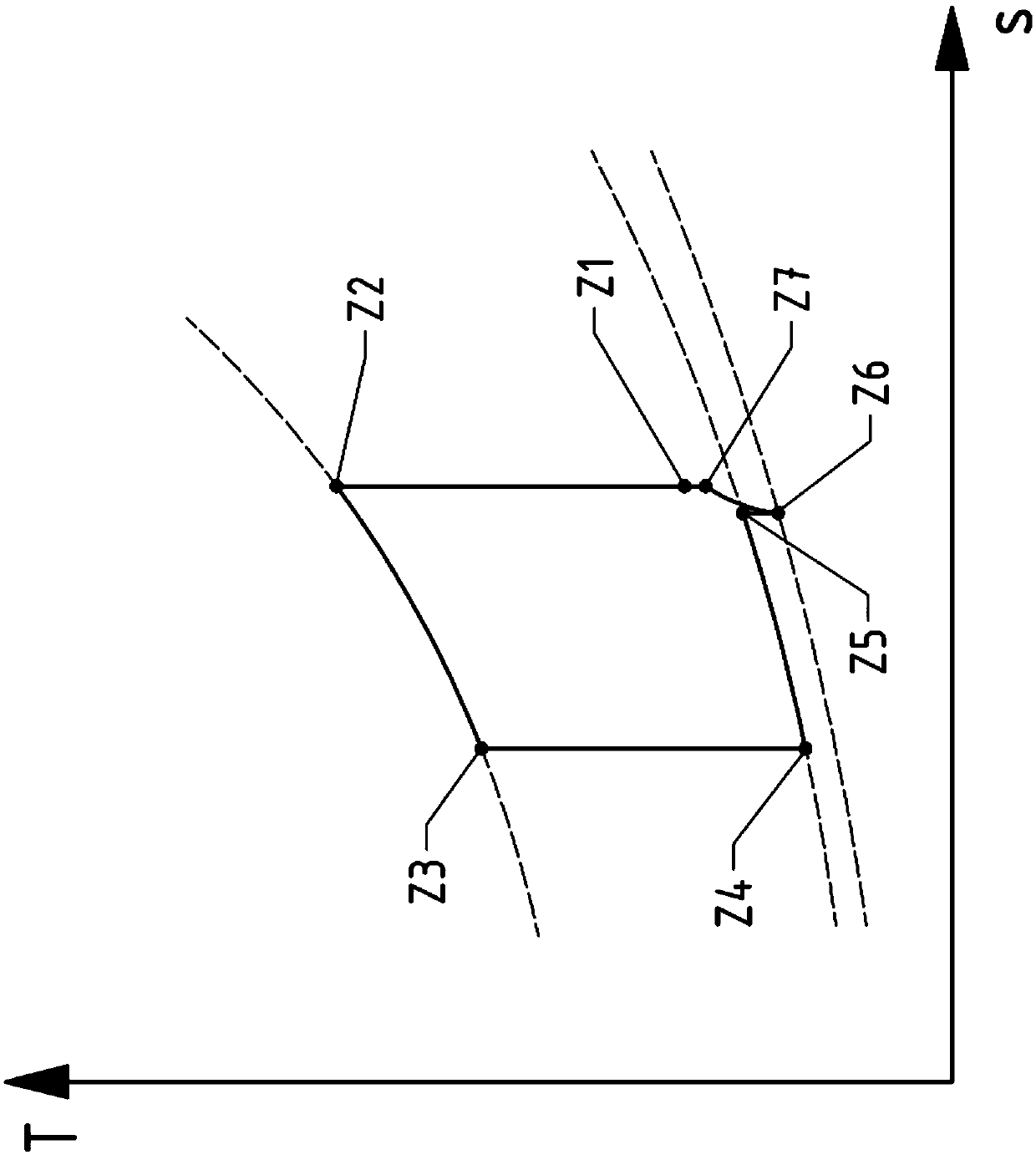

[0045] figure 1A device 20 for converting thermal energy by means of mechanical energy and reversing the process is shown, which in the embodiment shown acts as a heat pump. The device 20 contains a rotor 21 which can be rotated about an axis of rotation 22 by means of a motor (not shown). The rotor 21 has a compression unit 23 and a pressure reduction unit 24 which have flow channels for the working medium. While flowing through the rotor 21, the working medium, for example natural gas, passes through a closed cycle process with the working steps: a) compression of the working medium, b) between the working medium and the heat exchange medium in the external heat exchanger 1' between, c) depressurization of the working medium and d) heat exchange between the working medium and the heat exchange medium in the internal heat exchanger 1". For this purpose, the compression unit 23 has a substantially radially extending A compression channel 25 in which the working medium flows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com