A tool for installing the insulating sheath of a transmission wire

A technology for insulating sheaths and installation tools, which is applied in the direction of overhead lines/cable equipment, etc. It can solve the problems of slow operation speed, difficult operation, and laborious buckling action, and achieve the effect of simplifying installation work and reducing danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

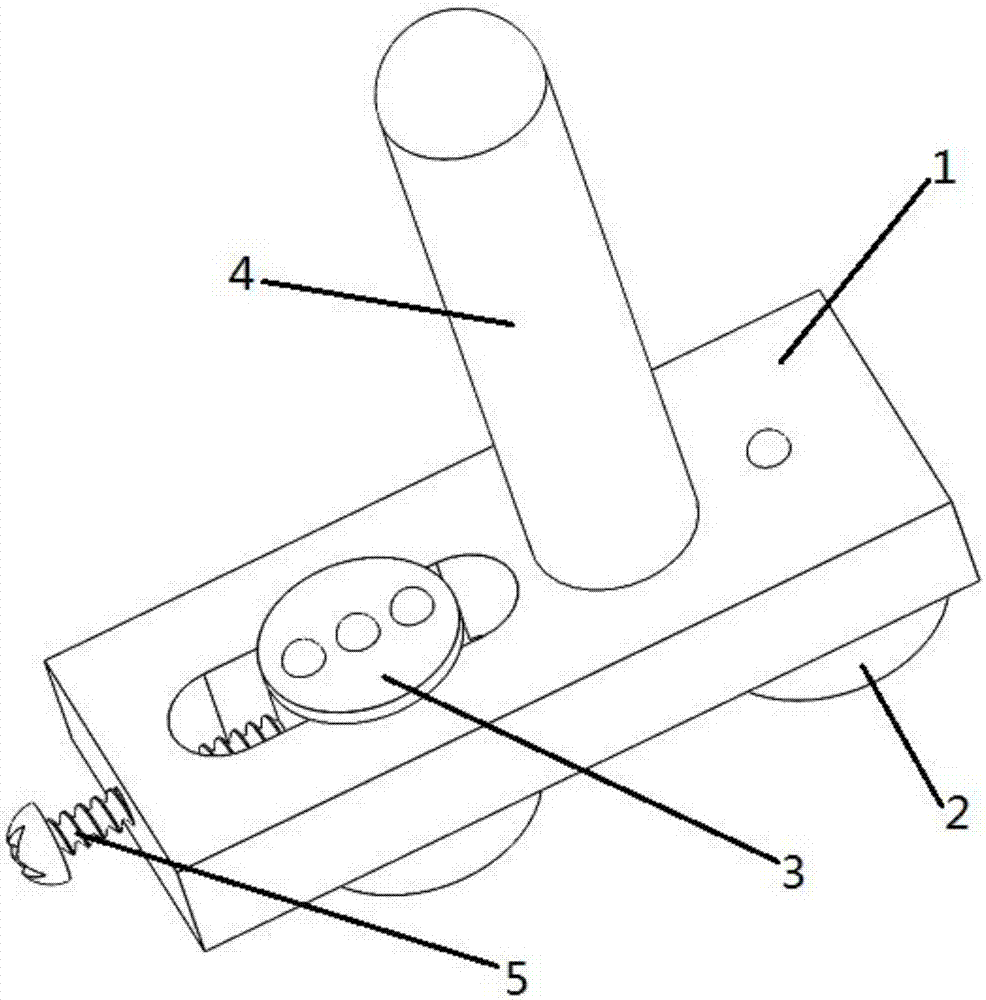

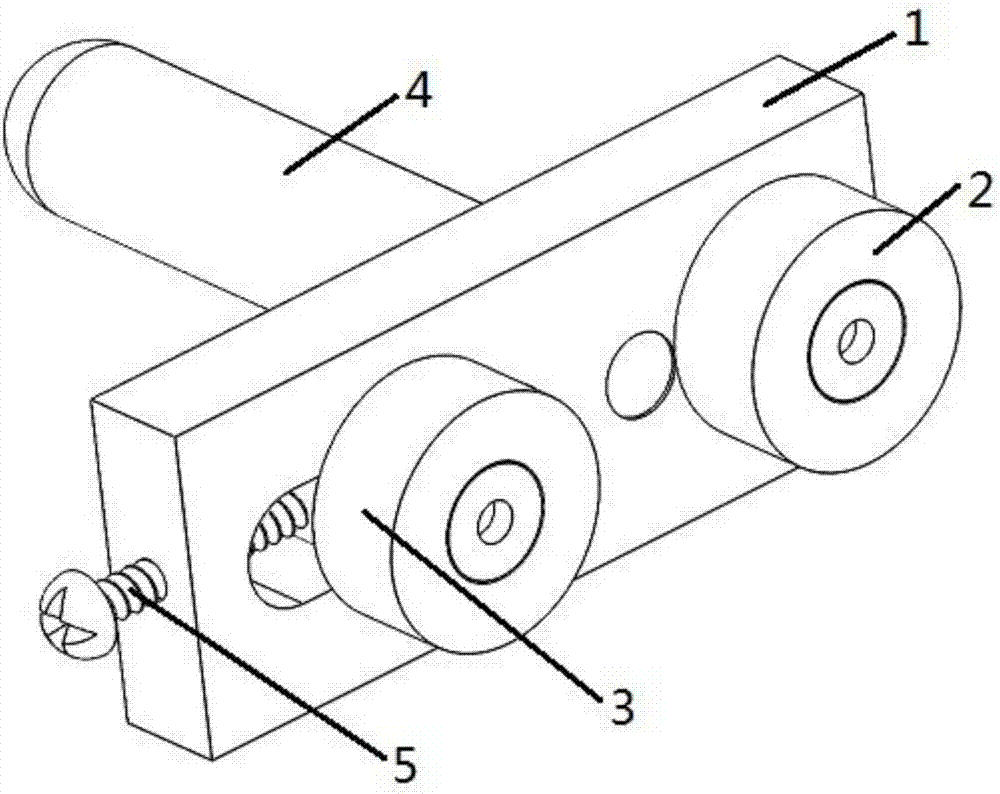

[0019] A tool for installing an insulating sheath of a power transmission wire, comprising a base plate 1, a fixed wheel 2, a moving wheel train 3, a handle 4, and a moving wheel train positioning member 5; wherein, the base plate 1 is provided with a mounting hole for the fixed wheel 2 and a mounting groove for the driving train 3; The driving wheel system 3 includes a sliding bar, a sliding bar baffle and a driving wheel. The driving wheel and the sliding bar baffle are installed on both sides of the sliding bar. 3. The installation groove slides; the moving wheel train positioning part 5 is a screw rod, which extends into the driving train 3 installation groove through the screw hole on the side of the base plate 1, and contacts with the sliding bar; the fixed wheel 2 is installed on the base plate 1 on the moving wheel side through the fixed wheel 2 mounting hole; The handle 4 is installed on the base plate 1 and is located on the opposite side of the moving wheel and the f...

specific Embodiment 2

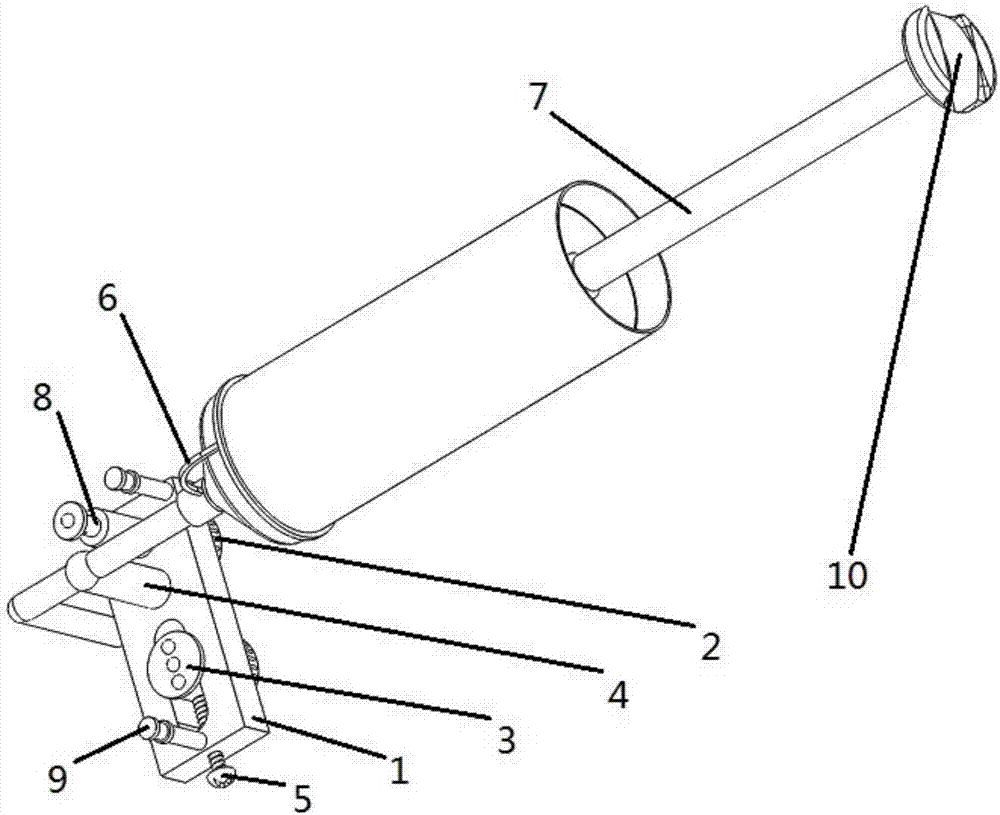

[0020] A tool for installing an insulating sheath of a power transmission wire, comprising a base plate 1, a fixed wheel 2, a moving wheel train 3, a handle 4, a moving wheel train positioning member 5, a rubber tube mounting frame 6, a rubber extruding rod 7, a guide shaft 8 and a winding shaft 9; Among them, the base plate 1 is provided with a mounting hole for the fixed wheel 2 and a mounting groove for the moving wheel system 3; the moving wheel system 3 includes a slider, a slider baffle and a moving wheel, and the moving wheel and the slider baffle are installed on both sides of the slider, and the slider passes through the moving wheel and the sliding bar baffle are embedded in the installation groove of the driving train 3 and can slide along the installation groove of the driving train 3; Contact; the fixed wheel 2 is installed on the moving wheel side of the base plate 1 through the mounting hole of the fixed wheel 2; the handle 4 is installed on the base plate 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com