Flexible photovoltaic cell product and preparation method thereof

A photovoltaic cell and photovoltaic power generation technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of reduced photoelectric conversion output, limited series and parallel connection of products, complicated steps, etc., to achieve easy portability and increase the effective lighting area , easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, so they are only examples, and should not be used to limit the protection scope of the present invention.

[0038] It should be noted that, unless otherwise specified, the technical terms or scientific terms used in this application shall have the usual meanings understood by those skilled in the art to which the present invention belongs.

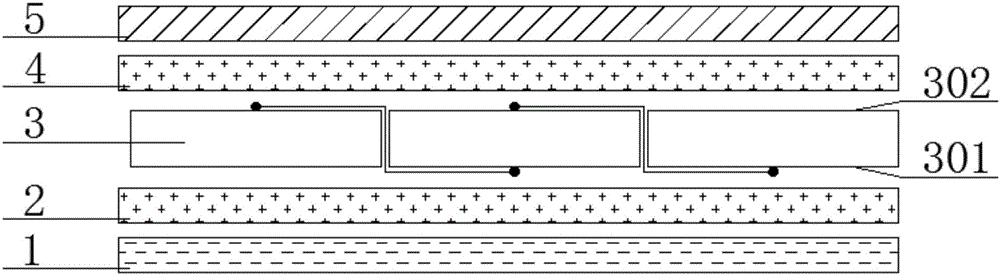

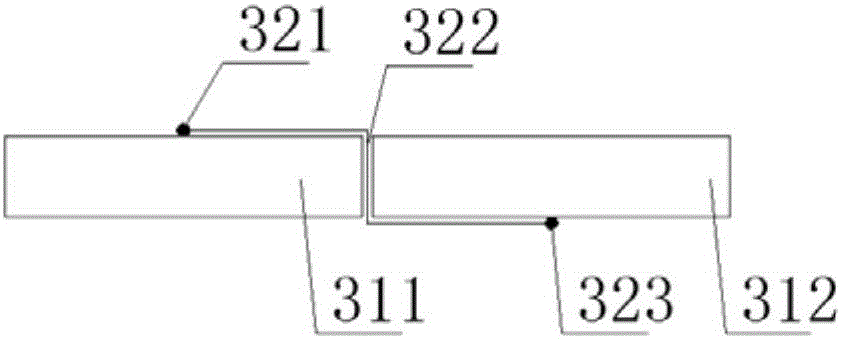

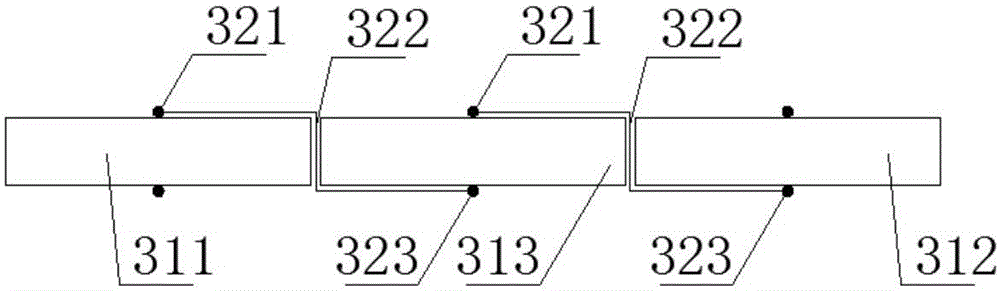

[0039] In the first aspect, an embodiment of the present invention provides a flexible photovoltaic cell product, which combines figure 1 or Image 6 , the flexible photovoltaic cell product includes a flexible photovoltaic cell assembly 100 and a magnetic sheet 200 disposed on the flexible photovoltaic cell assembly 100, the flexible photovoltaic cell assembly 100 includes a ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com