Eddy current detection uplift shake compensation method

A technology of eddy current detection and compensation method, applied in the direction of measurement device, electromagnetic measurement device, electromagnetic/magnetic thickness measurement, etc., can solve the problem of lack of compensation function and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

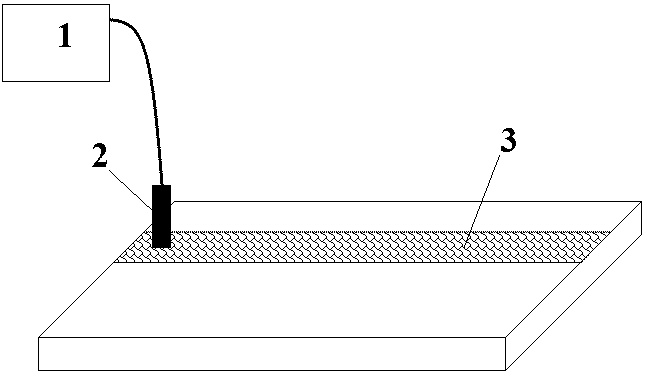

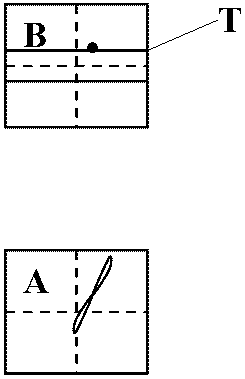

[0016] The first embodiment, such as figure 1 , figure 2 As shown, an eddy current detection lift-off shake compensation method, the eddy current detector 1 uses the main detection excitation signal and the auxiliary excitation signal to simultaneously excite the same eddy current detection coil 2, wherein the main detection excitation signal excites the eddy current detection coil 2 to detect defects in the weld 3 , the auxiliary excitation signal excites the eddy current detection coil 2 to detect the lift-off or shaking of the eddy current detection coil 2, the eddy current detector 1 sets the effective detection lift-off shaking signal threshold T, and the effective detection lift-off shaking signal threshold T is determined according to the detection sensitivity; When the eddy current detection coil 2 scans the weld 3, when there is lift-off or shaking, the main detection excitation signal excites the eddy current detection coil 2 to detect the defect signal A of the wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com